SECTION 7 MAINTENANCE AND SERVICING

169000

163

Revision F

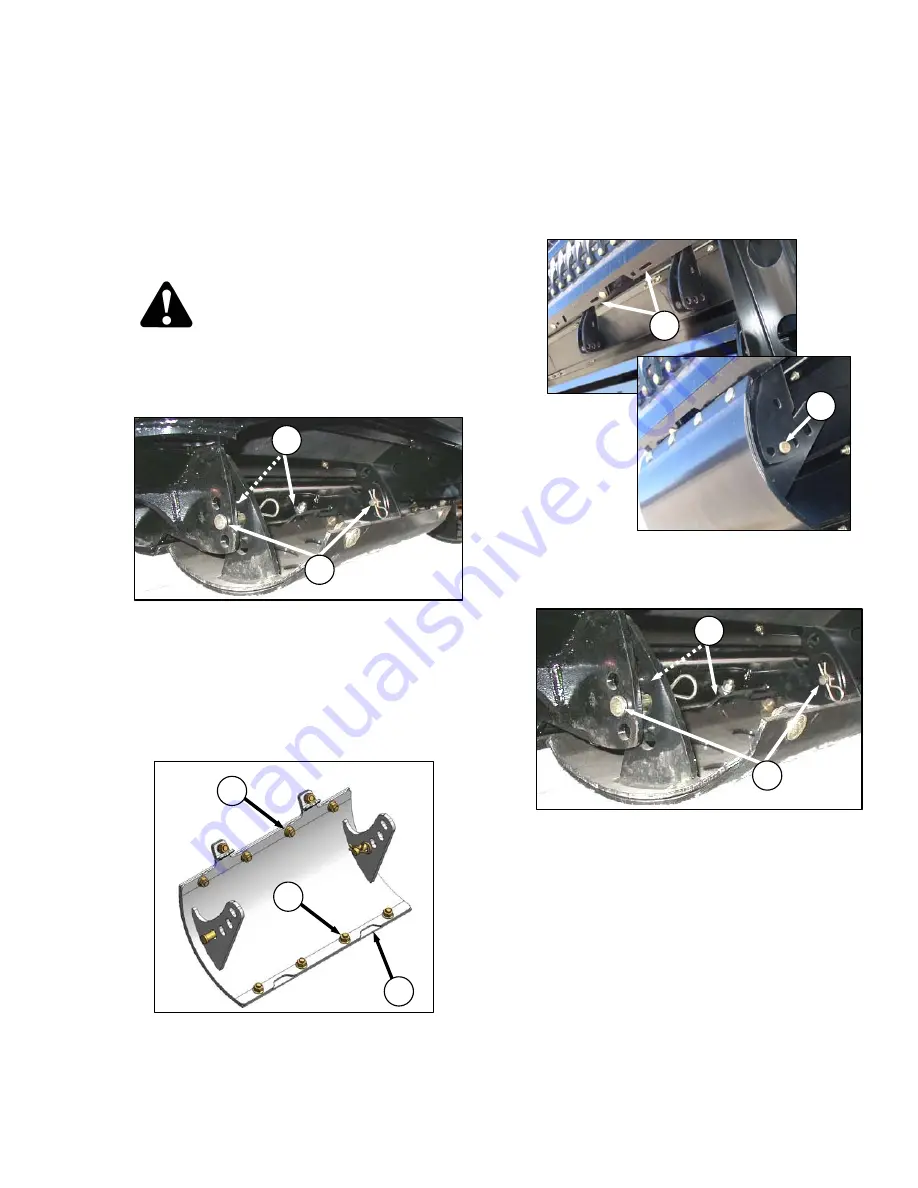

7.15 REPLACING SKID SHOE WEAR

PLATE

Skid shoes are equipped with replaceable wear

plates that can be reversed for increase service

life. It is recommended that wear plates be

replaced when the skid shoe weldment

becomes exposed.

a. Raise header, and engage lift cylinder stops.

CAUTION

Stop engine, and remove key from ignition

before leaving Operator’s seat for any

reason. A child or even a pet could engage

an idling machine.

b. Remove bolts (A), and clips from forward edge

of skid shoe.

NOTE

Use a socket and ratchet wrench to

access the nuts.

c. Remove clevis pins (B), and disengage tabs on

skid shoe from slots in cutterbar.

d. Remove eight bolts (C), and remove wear

plates (D).

e. Position replacement wear plate (D) as shown.

(The same wear plate can be reinstalled, but in

the reverse position).

f.

Secure wear plate with bolts and nuts (C).

IMPORTANT

If bolt heads are worn down, replace with

new 1/2 in. x 1 carriage bolts.

g. Insert tabs on skid shoe into slots (E) on

cutterbar at inboard mounting locations on

frame, and secure with clevis pin (B).

h. Reinstall clips (A) with bolts and nuts removed at

step b. to secure skid shoe to cutterbar.

NOTE

Use a socket and ratchet wrench to

access the nuts.

i. Remove clevis pin, adjust skid shoe to desired

height, and reinstall two clevis pins. Secure with

lynch pins.

A

B

E

B

A

C

C

C

D

Summary of Contents for A30-D

Page 2: ...MACDON A40 D SELF PROPELLED AUGER HEADER MACDON A30 D PULL TYPE MOWER CONDITIONER...

Page 3: ...169000 1 Revision F...

Page 4: ...169000 2 Revision F...

Page 6: ...169000 4 Revision F...

Page 181: ...NOTES 169000 179 Revision F...

Page 182: ......