MAINTENANCE/SERVICE

Form 169216

January 2009

22

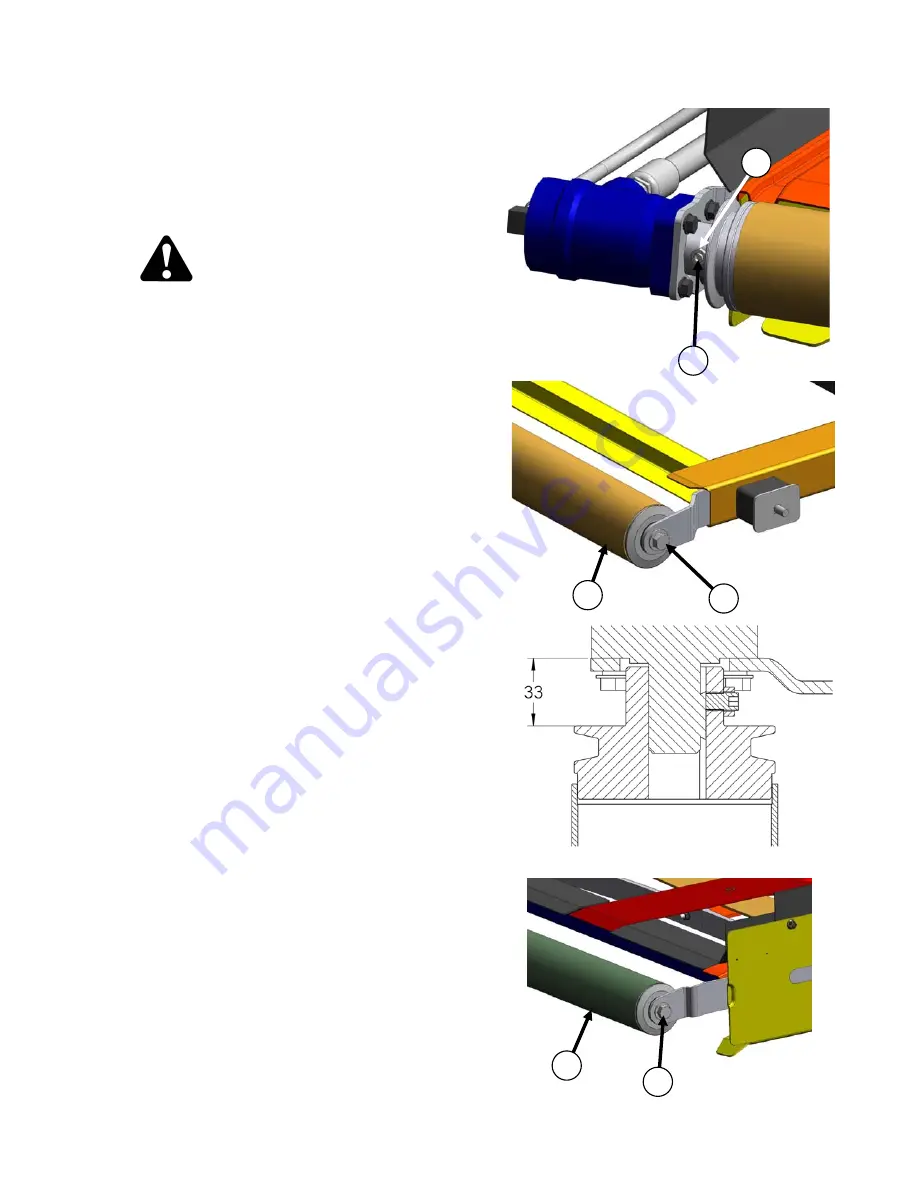

Draper Roller Maintenance:

The draper rollers have non-greaseable

bearings. The external seal should be checked

every 200 hours or more frequently in sandy

conditions to obtain the maximum bearing life.

Remove front skid to inspect seals.

DANGER

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine, stop engine, remove key and

engage safety pin before going under

machine for any reason.

Drive Roller:

1. Raise deck and engage safety pin.

2. Remove front skid, loosen and remove

draper. See page 21 for instructions.

3. Loosen two jam nuts (N) and set screws

(P).

4. At the front of the drive roller (S) remove

bolt and washer (R). The arm can be

pulled out of the deck.

5. Pull drive roller off of motor shaft.

6. Re-install drive roller in reverse order.

7. Apply grease to motor shaft.

8. Slide drive roller on to motor shaft.

Make sure it is fully engaged. The drive

roller should be 33 mm (1.3”) from the

face of the motor.

9. Install two set screws (P) with jam nuts.

Torque set screws to 20 ft-lbs (27 N-m).

10. Torque bolt (R) to 70 ft-lbs (95 N-m).

Idler Roller:

1. Raise deck and engage safety pin.

2. Remove front skid. Loosen draper.

Draper does not need to be removed

but removal will ease roller disassembly.

3. Remove idler roller (T) by removing bolt

and washer (R) at each end of roller.

4. Re-install idler roller in reverse order.

5. Torque bolts (R) to 70 ft-lbs (95 N-m).

P

N

R

T

R

S

Summary of Contents for M150 2009

Page 2: ...MACDON DOUBLE WINDROW ATTACHMENT ...

Page 26: ...MAINTENANCE SERVICE Form 169216 January 2009 24 Hydraulic Schematic ...

Page 30: ...Form 169216 January 2009 28 DECK DRAPER ROLLERS Illustration 2 ...

Page 32: ...Form 169216 January 2009 30 DECK SUPPORTS LINKAGE Illustration 1 ...

Page 34: ...Form 169216 January 2009 32 DECK SUPPORTS LINKAGE Illustration 2 ...

Page 36: ...Form 169216 January 2009 34 HYDRAULICS IN CAB ELECTRICAL ...

Page 38: ...Form 169216 January 2009 36 HYDRAULIC SERVICE COMPONENTS ...