262391

123

Revision A

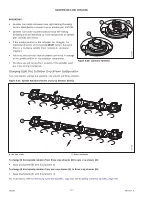

Inspecting Quick Change Plates

Check the thickness of the retaining bolts and the quick change plate using the supplied gauge.

DANGER

To prevent injury or death from the unexpected start-up or fall of a raised machine, always stop the engine and remove

the key from the ignition before leaving the operator

’

s seat or making adjustments to the machine. If the rotary disc

header is raised, always close the lock-out valves, and place blocks under the header. Never work on or beneath an

unsupported header.

DANGER

Ensure that all bystanders have cleared the area.

WARNING

Disc blades have two sharp cutting edges that can cause serious injury. Exercise caution and wear gloves when working

with, or near, blades.

DANGER

To avoid serious injury or death due to worn quick change plate, check the plates for damage before and after each

use. The wear limit of the quick change plate is reached when the application seam is worn away at one point. The

wear limit must be checked with a gauge.

1.

Position the rotary disc header at an appropriate height for the task.

2.

Shut down the engine, and remove the key from the ignition.

3.

If the rotary disc header is raised:

a.

Place blocks under each end, or just inside each end, of the cutterbar.

b.

Lower the rotary disc header onto the blocks.

c.

Shut down the engine, and remove the key from the ignition.

d.

Close the auxiliary lift cylinder lock-out valves. For instructions, refer to

3.2.1 Locking and Unlocking Auxiliary Lift

.

1033221

A

B

C

Figure 4.76: Installing Quick Change Blade

4.

Remove hairpin clip (A).

5.

Remove pin (B).

6.

Remove change tool (C).