262391

160

Revision A

1011164

A

B

C

D

E

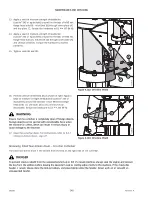

Figure 4.146: Cover Plate and Top Plate

14. Apply a bead of medium-strength threadlocker

(Loctite

®

243 or equivalent) around the threads of M10 hex

flange head bolt (B). Install bolt (B) through cover plate (A)

and top plate (C). Torque the hardware to 61 Nm (45 lbf·ft).

15. Apply a bead of medium-strength threadlocker

(Loctite

®

243 or equivalent) around the threads of M10 hex

flange head bolt (D). Install bolt (D) through cover plate (A)

and vertical shield (E). Torque the hardware to 61 Nm

(45 lbf·ft).

16. Tighten bolts (B) and (D).

1011078

A

B

Figure 4.147: Vertical Shield

17. Position vertical driveshield (B) as shown. Apply a bead of

medium-strength threadlocker (Loctite

®

243 or equivalent)

around the threads of four M10 hex flange head bolts (A).

Use bolts (A) to secure the vertical driveshield. Torque the

bolts to 61 Nm (45 lbf·ft).

WARNING

Ensure that the cutterbar is completely clear of foreign objects.

Foreign objects can be ejected with considerable force when

the machine is started, which can result in serious injury or

cause damage to the machine.

18. Close the cutterbar doors. For instructions, refer to

Closing Cutterbar Doors, page 27

Removing Large Non-Driven Drums

The non-driven large drums are held in place with four bolts.

DANGER

To prevent injury or death from the unexpected start-up or fall of a raised machine, always stop the engine and remove

the key from the ignition before leaving the operator

’

s seat or making adjustments to the machine. If the rotary disc

header is raised, always close the lock-out valves, and place blocks under the header. Never work on or beneath an

unsupported header.