262391

199

Revision A

4.7

Electrical System

The R1 FR's electrical system is powered by the tractor. The electrical harness from the header connects to the tractor and

supplies power to the position lights and the header lift assist system.

4.7.1

Maintaining Electrical System

Proper maintenance of the electrical system helps prevent future problems.

•

Use electrical tape and cable ties as required to prevent the wiring harness from dragging or rubbing.

•

Keep the lights clean and replace any defective bulbs or LED lights.

4.7.2

Replacing Amber Hazard/Signal Bulb

Replace the amber hazard or signal bulbs if they are damaged or inoperable.

DANGER

To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the

key from the ignition before leaving the operator

’

s seat.

DANGER

Ensure that all bystanders have cleared the area.

1.

Lower the header fully.

2.

Shut down the engine, and remove the key from the ignition.

1021281

A

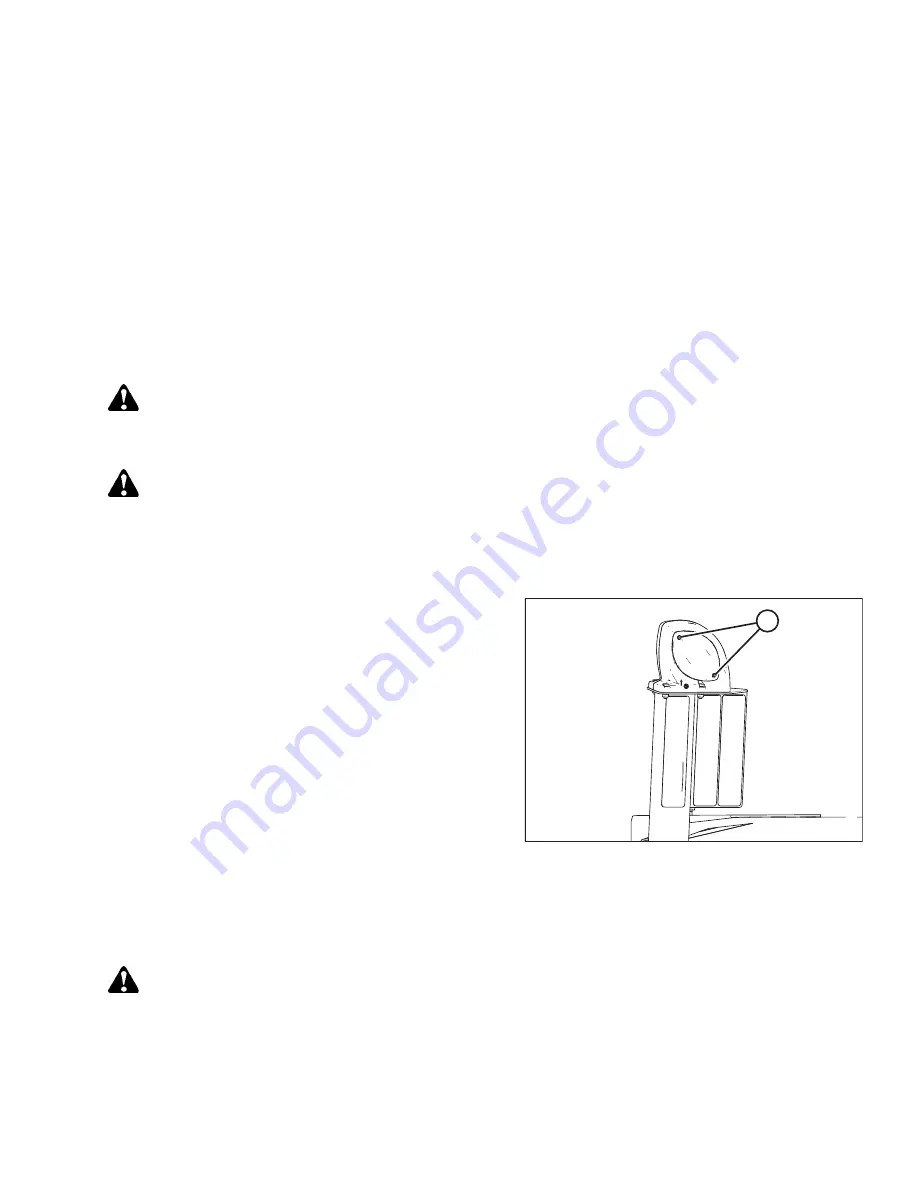

Figure 4.219: Plastic Lens and Screws

3.

Remove two Phillips screws (A) from the fixture. Remove

the plastic lens.

4.

Replace the bulb.

5.

Reinstall the plastic lens and screws.

4.7.3

Inspecting Auxiliary Lift System Sensors

Sensors are used to determine when the auxiliary lift cylinders are activated to adjust the header position.

DANGER

To prevent bodily injury or death from the unexpected start-up or fall of a raised machine, stop the engine, remove the

key from the ignition, and engage the lift cylinder lock-out valves before going under the machine.