262391

119

Revision A

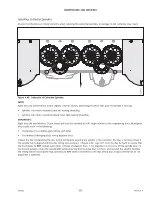

1004027

A

B

C

Figure 4.69: Disc Blade Aligned with Hole in

Rock Guard

4.

Rotate disc (A) so blade (B) faces forward and lines up with

hole (C) in the rock guard.

1004028

B

C

A

Figure 4.70: Disc Blade

5.

Place a pin (or equivalent) in the front hole of the rock

guard to prevent the disc from rotating while loosening

blade bolts.

6.

Clean debris from the blade attachment area.

7.

Remove nut (A) and discard it.

IMPORTANT:

Nuts are one-time use items. When flipping or replacing a

blade, replace it using a

NEW

nut.

8.

Remove shoulder bolt (B) and blade (C).

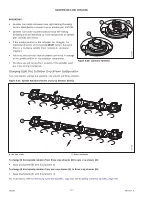

Installing Disc Blades

Check the disc blade hardware for damage while you are installing the disc blades. Be sure to always use new nuts when

installing disc blades.

DANGER

To prevent injury or death from the unexpected start-up or fall of a raised machine, always stop the engine and remove

the key from the ignition before leaving the operator

’

s seat or making adjustments to the machine. If the rotary disc

header is raised, always close the lock-out valves, and place blocks under the header. Never work on or beneath an

unsupported header.

DANGER

Ensure that all bystanders have cleared the area.

WARNING

Disc blades have two sharp cutting edges that can cause serious injury. Exercise caution and wear gloves when working

with, or near, blades.