9

When printing bottom layer, Observe the print nozzle .If the material can not be pasted on the hotbed, you need to Adjusting nut coun-

terclockwise. If the tape was broken, you need to Adjust the nut clockwise. the best print state is that the material paste on hot bed is

like flat ribbon rather than strips or flat shape.

CHAPTER3

PRINTING OPERATION

3.1

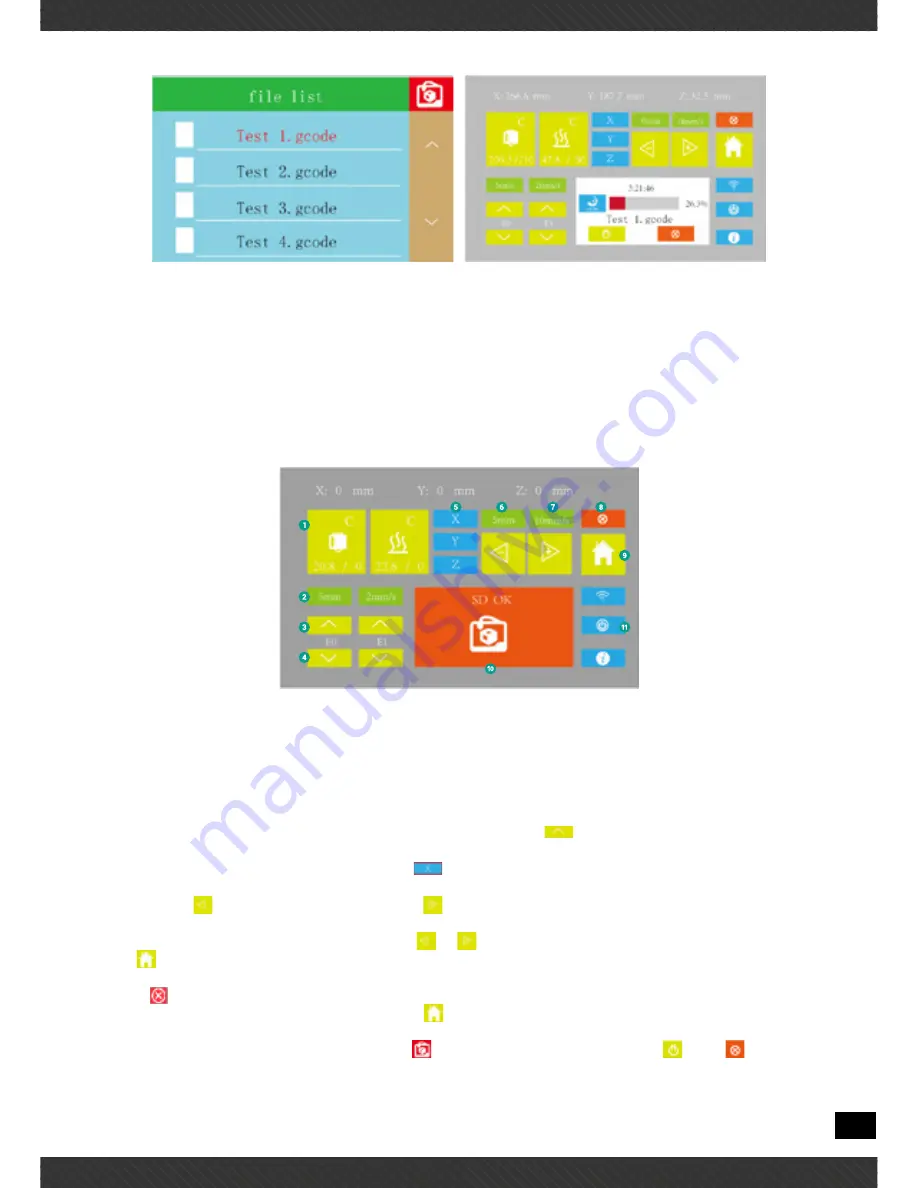

Display

1.

XYZ axis coordinate values displayed in real time

2.

Head preheating and Bed preheating: press the icon, input a number and click OK, it will begin to heat while the icon turns red.

Click again to cancel heating

3.

Length and speed of extrusion: It can be manual adjusted

4.

Extrusion and Retraction: E0 is to left extruder while E1 is to right extruder. E0 and E1 will be the same if there is only one extruder

in machine.

Attention:

For double extruders , head 1 and 2 mean E0 and E1 in repetier host

Icon means retraction, we suggest not use

retraction, it may cause extruder blocked

5.

XYZ axis: It will show red border when clicking the icon

, then you can click to move the head or bed.

6.

Length and speed of moving: moving settings of head, also it can be manual adjusted

7.

Moving: Icon

means moving towards zero axis, icon

means moving outwards from zero axis. Zero axis is located in upper

left corner of front print area.

When moving , choose X, Y or Z axis first, then click icon

or

to move. When coordinate shows zero, that you can only click

icon

to move towards zero axis

8.

Unlock the motors: If you click, the motors will be unlocked, then you can push printing head by hand. You can stop moving by click

button

at any time.

9.

Reset: When choosing X、Y or Z axis, you can press icon

to reset that axis you choose. If there is not any axis to be chosen, it

will reset XYZ axis in turn.

10.

Card: Click into SD card, select file ,and click button

on top right corner to print. You can pause

or stop

printing at

ay time

Attention:

It may need several seconds to preheat before printing.

11.

Wifi, Automatic shutdown and system information: This machine is not installed components, not for use temporary

Summary of Contents for EB-3DP322-017

Page 1: ......

Page 2: ...2 REV 020817 ...

Page 13: ...13 NOTE ...

Page 14: ...14 ...

Page 15: ......

Page 16: ...16 ...