5

CHAPTER1

OVERVIEW

1.1

Overview

PRISMA Series Desktop 3D Printers through the stl file into gcode document production model. The printer make part in the following

ways: through computer-controlled printing nozzle, squeeze ABS or PLA material that can be used to produce high-quality parts.

PRISMA Series Desktop 3D Printers product dimensions and sizes can be made as follows. Materials available for each material

carrier is equipped with 1000g, enough to make about 120 hours in a row without having to reload, and you can add a second material

to extend time.

Product Dimensions (W×D×H)mm

300×350×380

The size can be made (W×D×H)mm

150×150×150

1.2

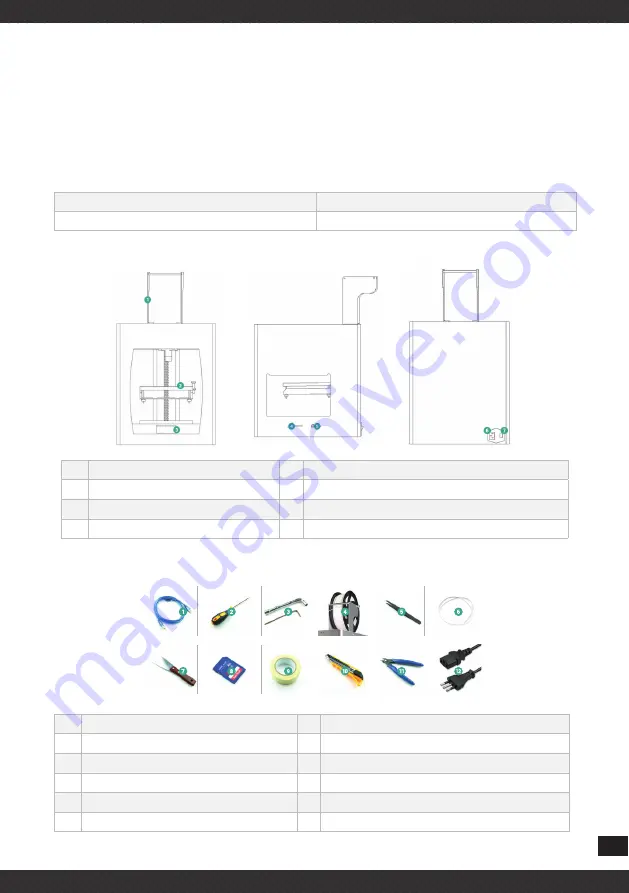

Front, Left and Back View

1

Material shelf

5

USB port

2

Print platform

6

Power Socket

3

Display panel

7

ON/OFF Button

4

SD card slot

1.3

Start Kit Contents

1

Jumper cable

7

Scraper knife

2

Screwdriver

8

SD card

3

Extrusion nozzle, Hexagon screw, Wrench, socket

9

Masking tape

4

Material shelf

10

Art knife

5

Tweezer

11

Diagonal pliers

6

Feeding tube

12

Power cable