9

ELECTRICAL CONNECTIONS

Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply through

an approved 13 amp BS 1363 plug, or a suitably fused isolator switch.

WARNING! THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in the mains lead are coloured in accordance with

the following code:

Green & Yellow

-

Earth

Blue

-

Neutral

Brown

-

Live

As the colours of the flexible lead of this appliance may not correspond with the

coloured markings identifying terminals in your plug proceed as follows:

•

Connect GREEN & YELLOW cord to terminal marked with a letter “E”

or Earth symbol “ ” or coloured GREEN or GREEN & YELLOW.

•

Connect BROWN cord to terminal marked with a letter “L” or

coloured RED.

•

Connect BLUE cord to terminal marked with a letter “N” or coloured

BLACK.

If this appliance is fitted with a plug which is moulded onto the electric cable

(i.e. non-rewireable) please note:

1.

The plug must be thrown away if it is cut from the electric cable.

There is a danger of electric shock if it is subsequently inserted into a

socket outlet.

2.

Never use the plug without the fuse cover fitted.

3.

When replacing a detachable fuse carrier, ensure the correct

replacement is used (as indicated by marking or colour code).

4.

Replacement fuse covers can be obtained from your local dealer

or most electrical stockists.

FUSE RATING

The fuse in the plug must be replaced with one of the same rating

(13 amps)

and this replacement must be ASTA approved to BS1362.

We strongly recommend that this machine is connected to the mains supply via

a Residual Current Device (RCD)

If in any doubt, consult a qualified electrician. DO NOT attempt any repairs

yourself.

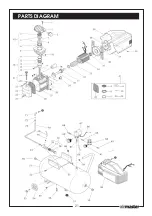

Summary of Contents for airmaster TIGER 9/24

Page 1: ...1 TIGER 9 24 AIR COMPRESSOR OPERATION MAINTENANCE INSTRUCTIONS 1107...

Page 21: ...21 PARTS DIAGRAM...

Page 23: ...23...

Page 24: ...24...