© Copyright. Machine Solutions Inc. All Rights Reserved

PM-62319 REV B

17

Equipment User Manual

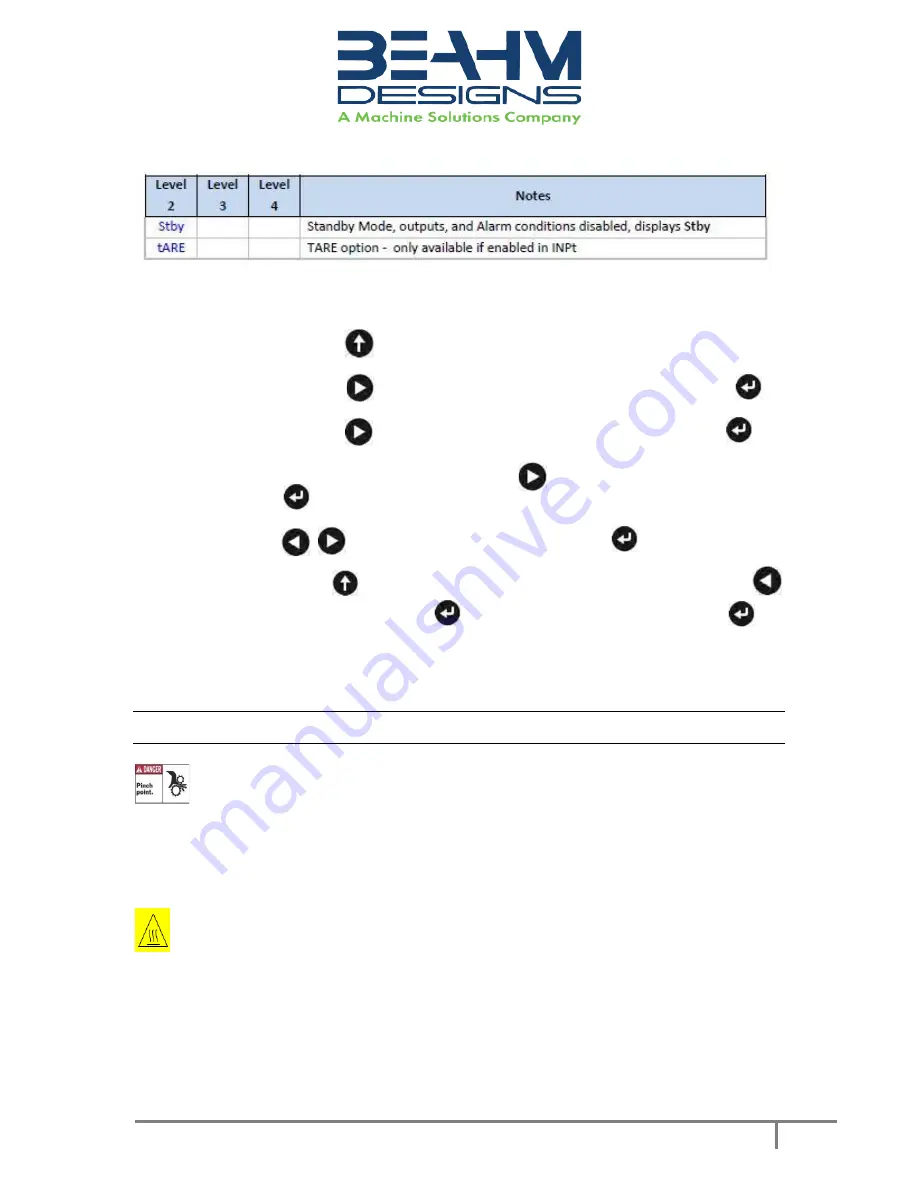

Changing Temperature Units on the Omega Temperature Controller

1.

Press the up button

until “oPER” appears on the screen.

2.

Press the right arrow

until

“1 NI t”

appears on the screen. Press enter.

3.

Press the right arrow

until

“RdG”

appears on the screen. Press enter.

4.

“dEC.P”

should be on screen. Press right arrow

to show “

°F °C

” on

the screen.

Press enter.

5.

Use arrows

to switch from °C to °F. Press enter.

6.

Press the up arrow

to go back to the “1 NI t” scree

n. Press the left arrow

to go

back to “oPER”

. Press enter

to see “RUN” and

press enter again

to return to normal operating status.

Maintenance

Caution: pinch point/crush hazard. Keep fingers, hands, and clothing

clear of moving parts.

1.

Use 99% isopropyl alcohol to wipe down the outside of the machine. Do not

attempt to clean the inside of the machine. The machine should not be washed

down.

2.

Cleaning should be with a soft dry cloth only.

Warning

Note: Ensure the machine is unplugged for any servicing or maintenance work.

Note: Perform these steps ONLY when the machine is at room temperature.

Summary of Contents for BEAHM DESIGNS 43-B

Page 1: ...BEAHM DESIGNS BENCH TOP DIE NECKER MODEL 43 B...

Page 9: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 9 Equipment User Manual...

Page 10: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 10 Equipment User Manual...

Page 11: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 11 Equipment User Manual...

Page 12: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 12 Equipment User Manual...

Page 14: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 14 Equipment User Manual...

Page 15: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 15 Equipment User Manual...