© Copyright. Machine Solutions Inc. All Rights Reserved

PM-62319 REV B

7

Equipment User Manual

Autotune (PRoG > PId > TUNE)

Select the Autotune (AUto) command. The unit displays StRt.

Confirm Autotune activation. The unit attempts to optimize the P, I, and d

settings by stimulating the system and measuring the response. If the A.to

time out period expires before the Autotune operation can complete, the

unit displays a failure message E007. If the Autotune operation completes

successfully, the unit displays the message “doNE” and the Run mode is

switched to IDLE.

The Autotune function will select the tuning algorithm depending on the stability of

current process and the error difference between current process and the Control

Setpoint (SP1). If the process is relatively stable (i.e: at room temperature), a bump test

will be performed to determine the plant characteristics.

If the process is hot, or if the process is within 10% of Control Setpoint, limit cycle

oscillation will be performed with the tuning setpoint taken at the process value when

the Autotune function is triggered. Autotuning may be performed as many times as

needed or when the operating conditions (i.e: process load, or setpoint) have changed

significantly. To obtain good tuning results, ensure the process is stable prior to

triggering autotune function. The process is stable when it is at ambient temperature, or

it is tracking Control Setpoint (SP1) in auto mode.

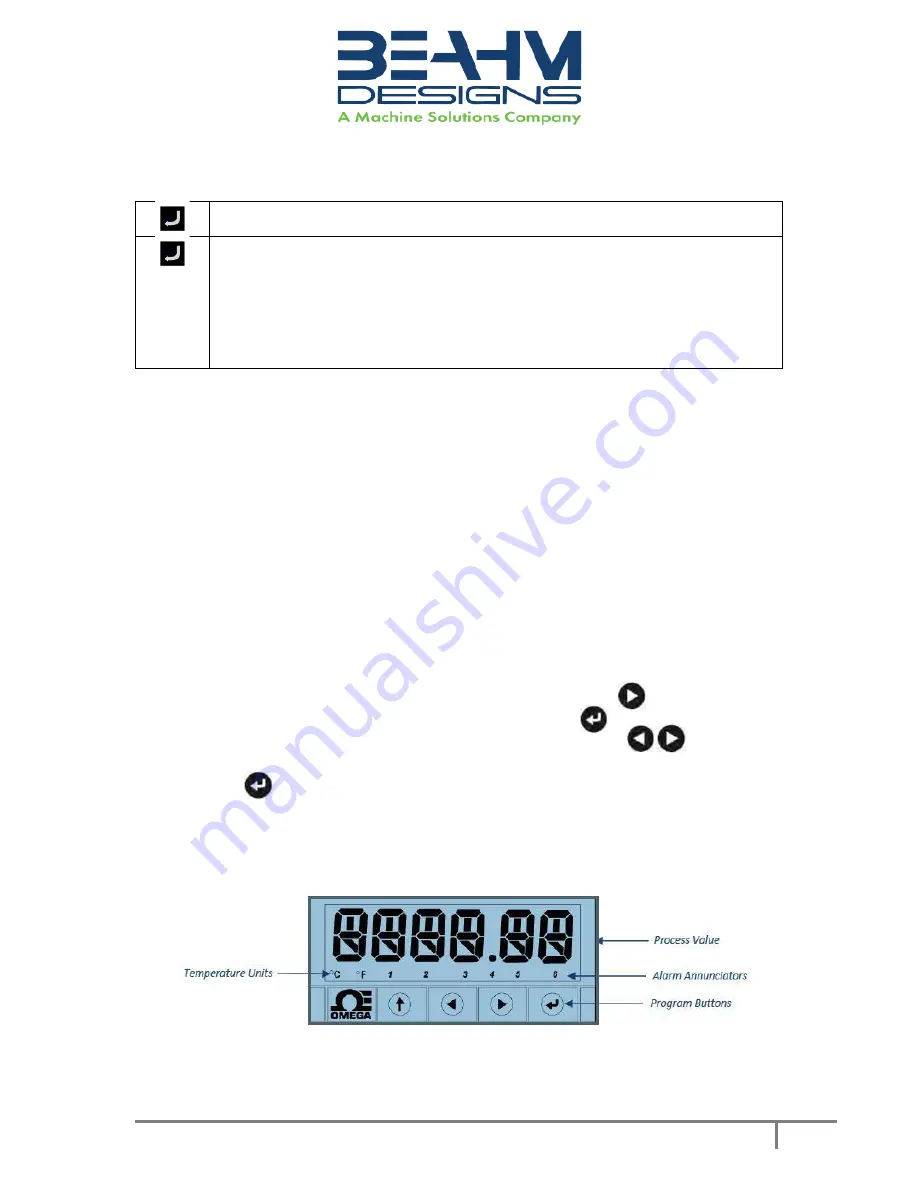

Adjusting Temperature on Controllers (Omega Platinum Model)

1.

Press the right arrow button one time until “SP

-

1” is displayed.

2.

Press the enter button to access the temperature screen.

3.

Use the left and right arrow buttons to set desired temperature.

4.

Once the desired temperature is set, press the enter button to return to the main

screen. Heaters will ramp to correct temperature.

Temperature Controller Layout and Description of Button Actions

Figure 1. Controller Layout

Summary of Contents for BEAHM DESIGNS 43-B

Page 1: ...BEAHM DESIGNS BENCH TOP DIE NECKER MODEL 43 B...

Page 9: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 9 Equipment User Manual...

Page 10: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 10 Equipment User Manual...

Page 11: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 11 Equipment User Manual...

Page 12: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 12 Equipment User Manual...

Page 14: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 14 Equipment User Manual...

Page 15: ...Copyright Machine Solutions Inc All Rights Reserved PM 62319 REV B 15 Equipment User Manual...