7

OPERATION MANUAL

UNPACKING

This machine was carefully packaged for safe transport. When unpacking, separate all enclosed

items from packaging materials and inspect them for shipping damage. If items are damaged,

please contact your distributor.

NOTE: Save all the packaging materials until you are completely satisfied with the machine and

have resolved any issues with the distributor, or the shipping agent.

When unpacking, check the packing list to make sure that all parts shown are included. If any

parts are missing or broken, please contact the your distributor.

4 SETUP

The unpainted surfaces of the machine have been coated with a waxy oil to protect them from

corrosion during shipment. Remove the protective coating with a solvent cleaner or a citrus

based degreaser.

Optimum performance from your machine will be achieved when you clean all moving parts or

sliding contact surfaces that are coated with rust prevented products.

It is advised to avoid chlorine based solvents, such as acetone or brake parts cleaner, as they

will damage painted surfaces and strip metal should they come in contact. Always follow the

manufacturer’s instructions when using any type of cleaning product.

CLEAN - UP

SITE PREPARATION

When selecting the site for the machine, consider the largest size of workpiece that will be

processed through the machine and provide enough space around the machine for operat-

ing the machine safely. Consideration should be given to the installation of auxiliary equip-

ment. Leave enough space around the machine to open or remove doors/covers as required

for the maintenance and service as described in this manual.

It is recommended that the machine is anchored to the floor to prevent tipping or shifting. It

also reduces vibration that may occur during operation.

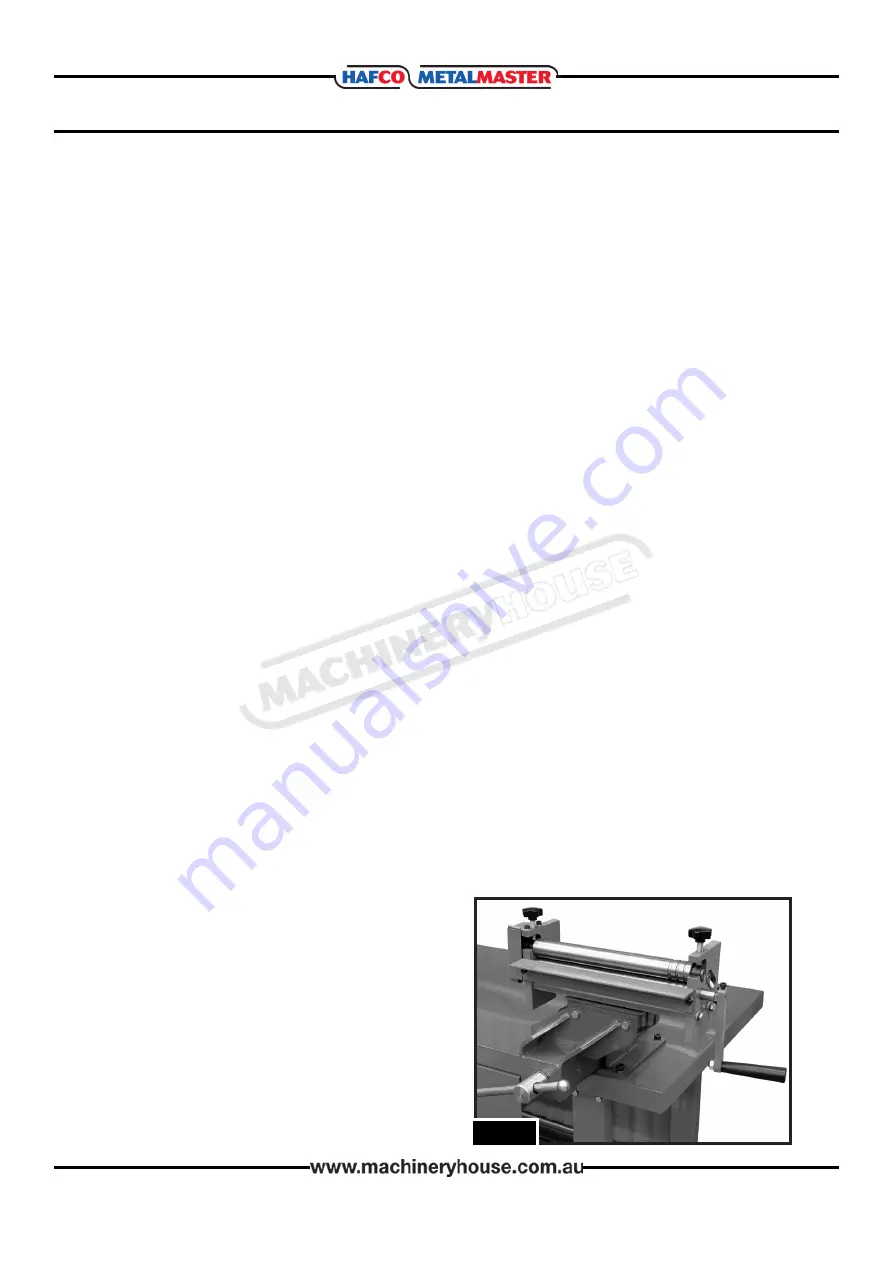

MOUNTING IN VISE

There are substantial forces exerted on the metal

curving rolls during operation. With this in mind,

the curving roll must be firmly secured in a vise

that is solidly attached to a workbench that will

support the weight and dynamic forces of the

operation. (Fig. 2)

F

ig

. 2