TROUBLESHOOTING

Page 103

Core Inspection

GUIDELINES

With the exception of straightening minor bends

in the cold fins, the CMCAC core is not repairable

and should be replaced when more extensive

damage is encountered. To ensure that the

CMCAC system will function properly after repair

or replacement, a pressure/leak test is

recommended.

INSPECTION

1. Carefully inspect the entire system to

determine the exact location and extent of

damage.

2. Inspect the cold fins and cold bars that run

horizontally in the cooler.

3. Inspect all brazed or welded joints in the

header tank.

CMCAC Preventive Maintenance

In case of engine and/or turbocharger failure, the

charge air cooler should be flushed to make sure

the cooler is free of debris.

FLUSHING PROCEDURE

1. Remove the chassis-mounted cooler and

flush the inside with a safety solvent to

remove oil and other foreign debris.

2. Shake cooler to remove large pieces.

3. Wash with hot, soapy water. Rinse with

clean water and blow dry with compressed

air in the reverse direction of flow.

4. Carefully inspect cooler to ensure

cleanliness.

Do not use caustic cleaners when flushing the

cooler. Be extremely careful when handling the

cooler so as not to damage the core.

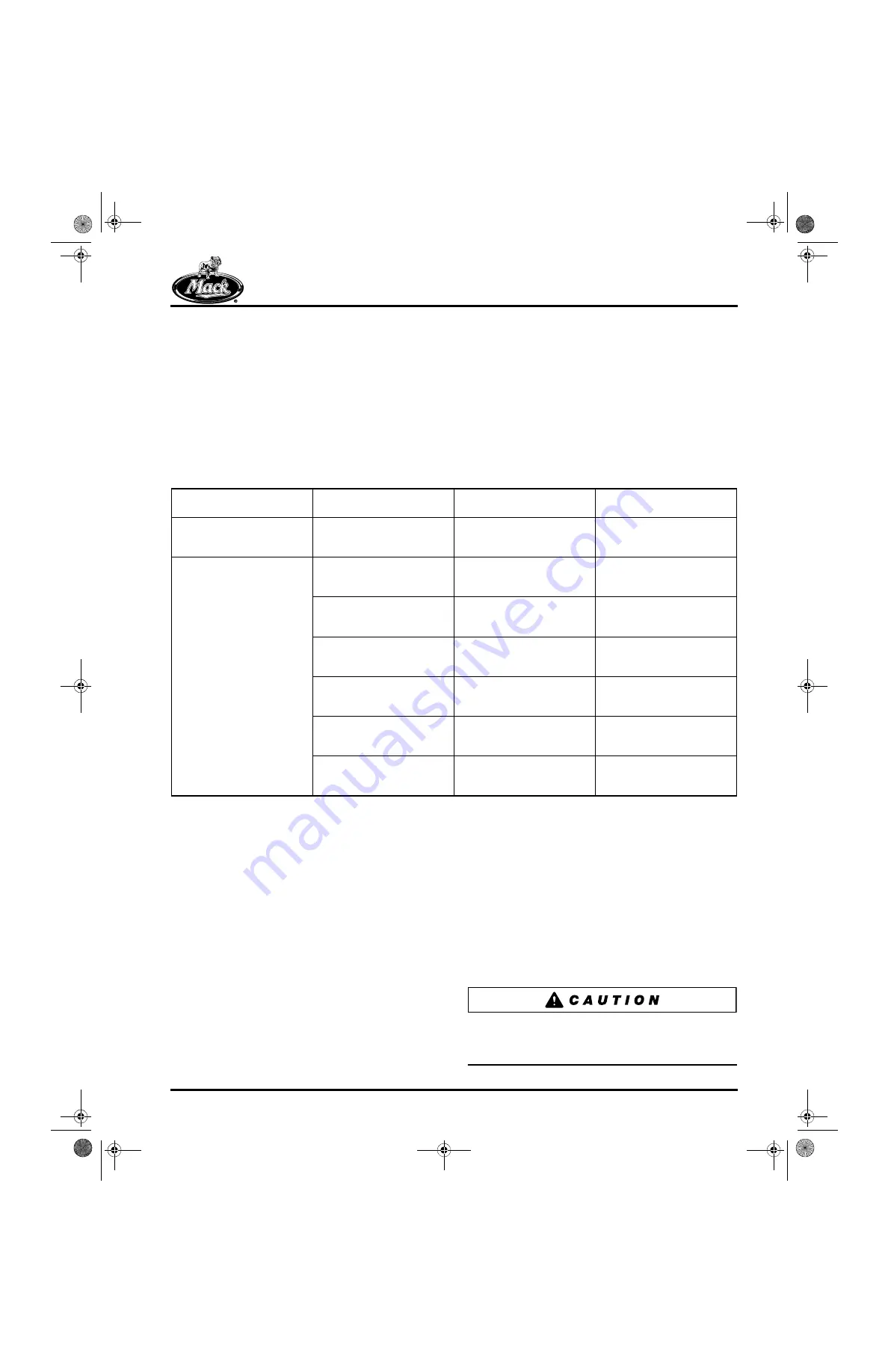

Damage

Core Failures

Recommended Repair

Procedure

System Check

Repairable

Bent cold fins

Straighten with small

screwdriver or pair of small

needlenose pliers.

Perform pressure/leak test.

Nonrepairable

All header tank-to-core

separations

No repair procedure is

recommended — replace

unit.

Perform pressure/leak test.

All header tank cracks

No repair procedure is

recommended — replace

unit.

Perform pressure/leak test.

Internal fins damaged and

separated from tube plate

No repair procedure is

recommended — replace

unit.

Perform pressure/leak test.

Tube blockage

No repair procedure is

recommended — replace

unit.

Perform pressure/leak test.

Tube/plate cracks or welds,

cold bar separations or

openings

No repair procedure is

recommended — replace

unit.

Perform pressure/leak test.

Excessive cold fin damage

(original shape of fins

distorted beyond repair)

No repair procedure is

recommended — replace

unit.

Perform pressure/leak test.

5-111.bk Page 103 Monday, July 10, 2006 2:26 PM

Summary of Contents for ASET AC

Page 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Page 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Page 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Page 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Page 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Page 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Page 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Page 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Page 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Page 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Page 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Page 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Page 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Page 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Page 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Page 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Page 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...