Page 366

REPAIR INSTRUCTIONS, PART 1

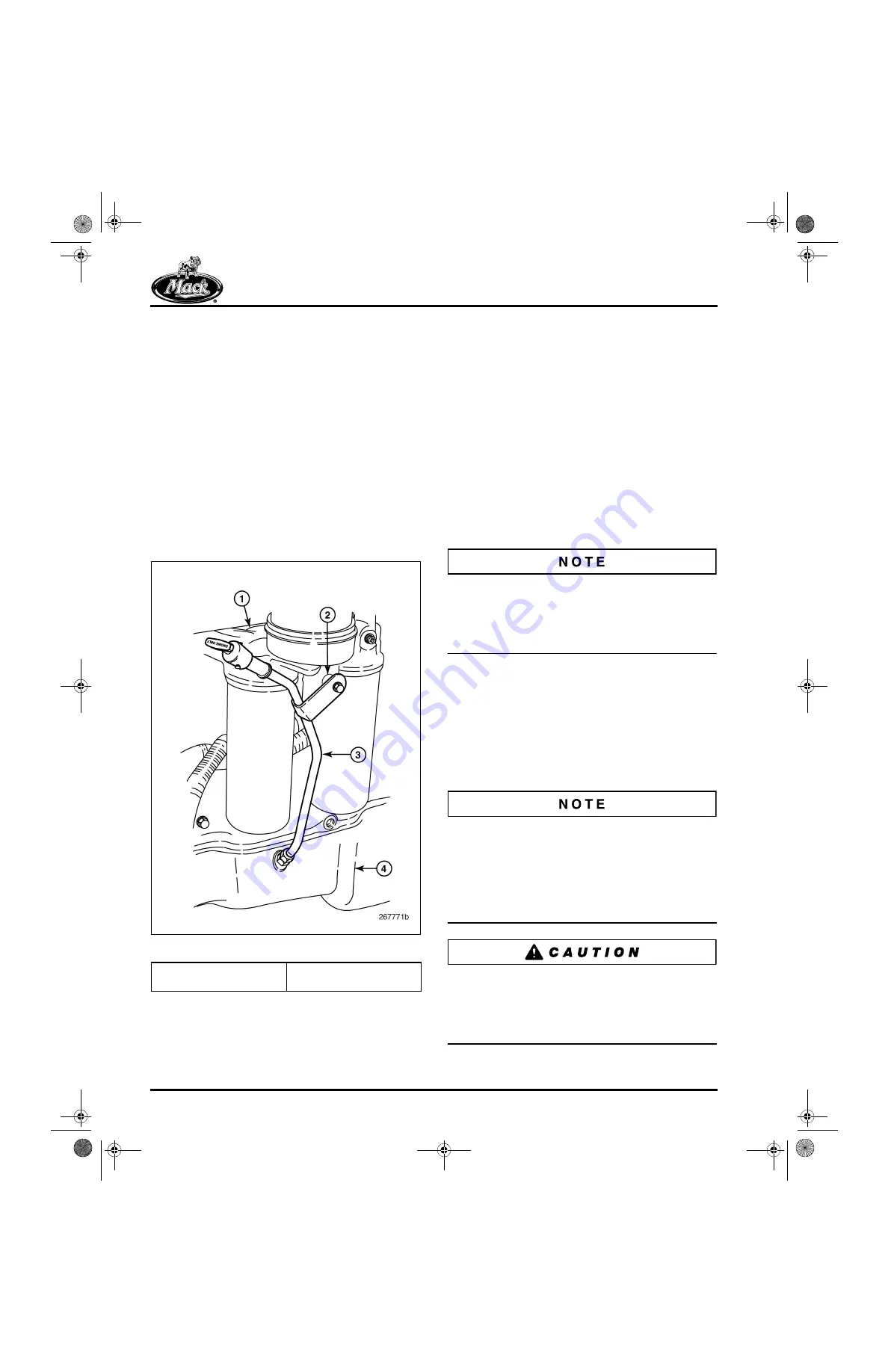

Dipstick Tube Installation

All AC engines have the dipstick tube installed in

the oil pan on the left side of the engine.

Installation instructions are as follows:

1. Install the tube guide into the side of the oil

pan and tighten the guide nut to

specifications.

2. Apply Loctite

®

242 (blue) to the threads of

the dipstick tube attaching capscrew.

3. Insert the dipstick tube into the guide tube

and attach the tube to the oil filter pedestal

bracket with the capscrew. Locate the

isolator between the tube bracket and oil

filter pedestal, as shown in Figure 443.

443

Figure 443 — Dipstick, Left-Side Installation

4. Tighten the dipstick tube attaching capscrew

to the specified torque of 24 lb-in (3 N

폷

m).

5. Install the dipstick guide tube compression

nut and tighten to specifications.

ENGINE INSTALLATION

General Instructions

Engine installation details vary from vehicle to

vehicle. The following procedure provides

general installation guidelines for MACK engines.

Before beginning, make sure all equipment has

been inspected for safety and is available for use.

Place the vehicle on a flat, level surface. Make

sure the area has ample work space.

Engine Installation into Vehicle

Obtain assistance when installing the engine. Be

sure to watch for obstructions, such as engine or

chassis components, brackets, clamps or other

components, that may interfere with installation of

the engine.

1. Using a suitable lifting device, lower the

engine into position on the chassis.

2. Align the engine with the torque converter or

clutch (as applicable) and install the

transmission bell housing-to-flywheel

housing capscrews. Tighten the capscrews

to specification which is dependent on size

of fastener.

A new-style flywheel housing initiated into

production in mid-2004, introduced a larger

transmission-to-flywheel housing connection bolt.

The bolt size increases from 10 mm to 7/16-inch.

This bolt size change will need to be considered if

the flywheel housing was replaced during

overhaul.

If the flywheel housing was replaced with the

new-style which uses a 7/16-inch

transmission-to-flywheel housing bolt, it is very

important to also use the correct hardened

washer with this bolt.

1. Filter Mounting Bracket

2. Isolator

3. Dipstick Tube

4. Oil Pan

5-111.bk Page 366 Monday, July 10, 2006 2:26 PM

Summary of Contents for ASET AC

Page 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Page 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Page 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Page 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Page 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Page 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Page 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Page 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Page 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Page 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Page 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Page 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Page 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Page 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Page 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Page 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Page 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...