REPAIR INSTRUCTIONS, PART 2

Page 433

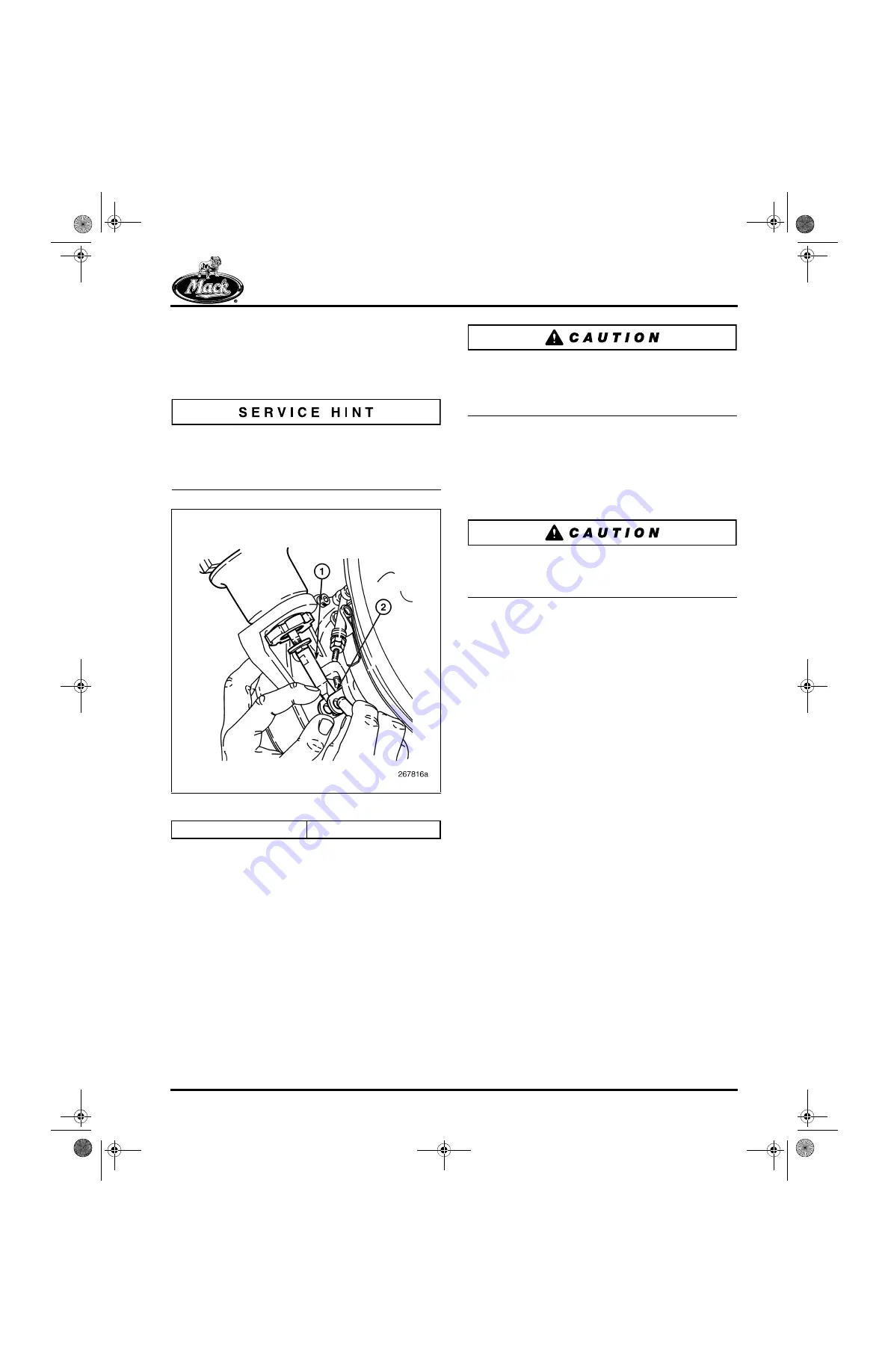

6. With air pressure applied and the actuator

rod extended, move the lever arm clevis to

align the hole in the clevis with the hole in

the rod end and insert the clevis pin

(Figure 530).

Because of preload, it is easier to install the pin

through the vane lever arm clevis and actuator

rod hole when the rod is in an extended position

and not retracted into the housing.

530

Figure 530 — Vane Operating Lever Connection

7. Set the pressure regulator to 0 psi. The

actuator rod should retract and pull the vane

operating lever against the upper stop

(vanes open).

8. Adjust the regulator to apply 95–100 psi of

shop air pressure to the actuator. The

actuator rod should extend, pushing the

vane operating lever down against the lower

stop (vanes fully closed).

Use care in applying air pressure to the actuator

assembly. DO NOT apply more than 100 psi.

Pressures greater than 100 psi will result in

damage to the actuator.

9. Verify that the lever arm clevis moves fully

from stop-to-stop. Then, carefully tighten the

actuator rod end jam nut to 106 lb-in

(12 N

폷

m) while using an open-end wrench

on the flats of the rod end to hold the end in

place.

Damage to the actuator diaphragm will occur if

the actuator rod is allowed to twist while

tightening the jam nut.

10. Install the C-clip to secure the secure the pin

in the lever arm clevis.

11. Disconnect the regulated shop air line from

the actuator and reconnect the air line from

the VTG position control valve to the

actuator. Tighten the fitting to 140 lb-in

(16 N

폷

m).

12. Re-calibrate the VTG actuating system for

proper open and closed vane-position

voltages using the procedure that follows in

this section.

13. After the VTG vane position calibration has

been successful, complete the installation

procedures by routing the vane position

sensor and turbocharger wheel speed

sensor wire harnesses as shown in

Figure 531.

1. Actuator Rod

2. Lever Arm Clevis

5-111.bk Page 433 Monday, July 10, 2006 2:26 PM

Summary of Contents for ASET AC

Page 6: ...TABLE OF CONTENTS Page iii TABLE OF CONTENTS 5 111 bk Page iii Monday July 10 2006 2 26 PM...

Page 14: ...INTRODUCTION Page 1 INTRODUCTION 5 111 bk Page 1 Monday July 10 2006 2 26 PM...

Page 23: ...Page 10 NOTES 5 111 bk Page 10 Monday July 10 2006 2 26 PM...

Page 96: ...COMPONENT LOCATOR Page 83 COMPONENT LOCATOR 5 111 bk Page 83 Monday July 10 2006 2 26 PM...

Page 99: ...Page 86 NOTES 5 111 bk Page 86 Monday July 10 2006 2 26 PM...

Page 100: ...TROUBLESHOOTING Page 87 TROUBLESHOOTING 5 111 bk Page 87 Monday July 10 2006 2 26 PM...

Page 140: ...MAINTENANCE Page 127 MAINTENANCE 5 111 bk Page 127 Monday July 10 2006 2 26 PM...

Page 153: ...Page 140 NOTES 5 111 bk Page 140 Monday July 10 2006 2 26 PM...

Page 383: ...Page 370 NOTES 5 111 bk Page 370 Monday July 10 2006 2 26 PM...

Page 479: ...Page 466 NOTES 5 111 bk Page 466 Monday July 10 2006 2 26 PM...

Page 480: ...SPECIFICATIONS Page 467 SPECIFICATIONS 5 111 bk Page 467 Monday July 10 2006 2 26 PM...

Page 505: ...Page 492 NOTES 5 111 bk Page 492 Monday July 10 2006 2 26 PM...

Page 513: ...Page 500 NOTES 5 111 bk Page 500 Monday July 10 2006 2 26 PM...

Page 519: ...Page 506 NOTES 5 111 bk Page 506 Monday July 10 2006 2 26 PM...

Page 520: ...APPENDIX Page 507 APPENDIX 5 111 bk Page 507 Monday July 10 2006 2 26 PM...

Page 528: ...INDEX Page 515 INDEX Index fm Page 515 Monday July 10 2006 2 48 PM...

Page 535: ...Page 522 NOTES Index fm Page 522 Monday July 10 2006 2 48 PM...