18

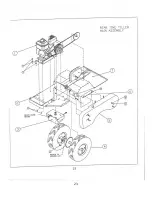

Inspection of Wheel Drive Transmission

The front bottom housing should be regularly removed for cleaning. To access this area, loosen 4 bolts that secure front

bumper, remove the 2 front bolts and pivot bumper up, undo latches that secure housing and remove housing.

Transmission and shift linkage should be inspected and drive chain and sprocket should be lubricated regularly. When it is

necessary to make internal repairs to the transmission, it is recommended that you contact your nearest authorized

Tecumseh/Peerless service center.

If excessive play develops in the shift pattern, you should inspect the transmission shift arm for elongation of the hole where

it attaches to the transmission. The bottom housing will need to be removed to access this transmission.

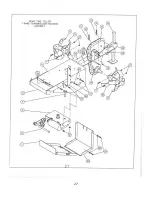

Right Angle Drive Lubrication and Maintenance

The normal recommended oil level should be near the center of the horizontal shaft. The oil level should be

checked at least after every 100 hours of operation. It is advisable to change the lubricant after the first 500

hours of operation and flush the unit out with a light oil prior to refilling. It is recommended that the oil be

changed every six months or every 2,500 hours of operation, whichever comes first.

If the unit is going to be idle for a period of several months, it should be drained, flushed and filled with a light

rust inhibiting oil.

The recommended lubricant is AGMA 5EP oil if the unit is operated under normal operating conditions.

Engine Maintenance

By following the maintenance sched

ule in the engine owner’s manual you will ensure maximum engine and tiller

life. The engine will normally consume oil,

so check oil level regularly and before each use.

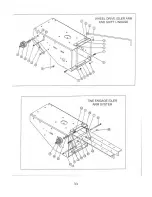

TIME TO CHANGE THE TINE SHAFT SEALS

Tine Shaft Seal Replacement Instructions

It is extremely important that the oil seals on the tiller transmission be inspected and replaced regularly to ensure

proper lubrication and to prevent dirt from entering the transmission. Both sides of the tine shaft have two oil seals.

These seals are inserted back to back over the tine shaft. The inner seal faces into the transmission and is

designed to keep lubricant from escaping from the transmission. The outer

seal faces outward and is designed to keep dirt out of the transmission. The

Merry Tiller t

ransmission is lubricated with heavy “00” grease. If the seals fail,

it may not be noticed due to the heavy consistency of the grease. This is the

best possible lubricant available and will add years of life to your Merry Tiller.

Seals should be inspected regularly and replaced as needed or before periods

of expected extended use.

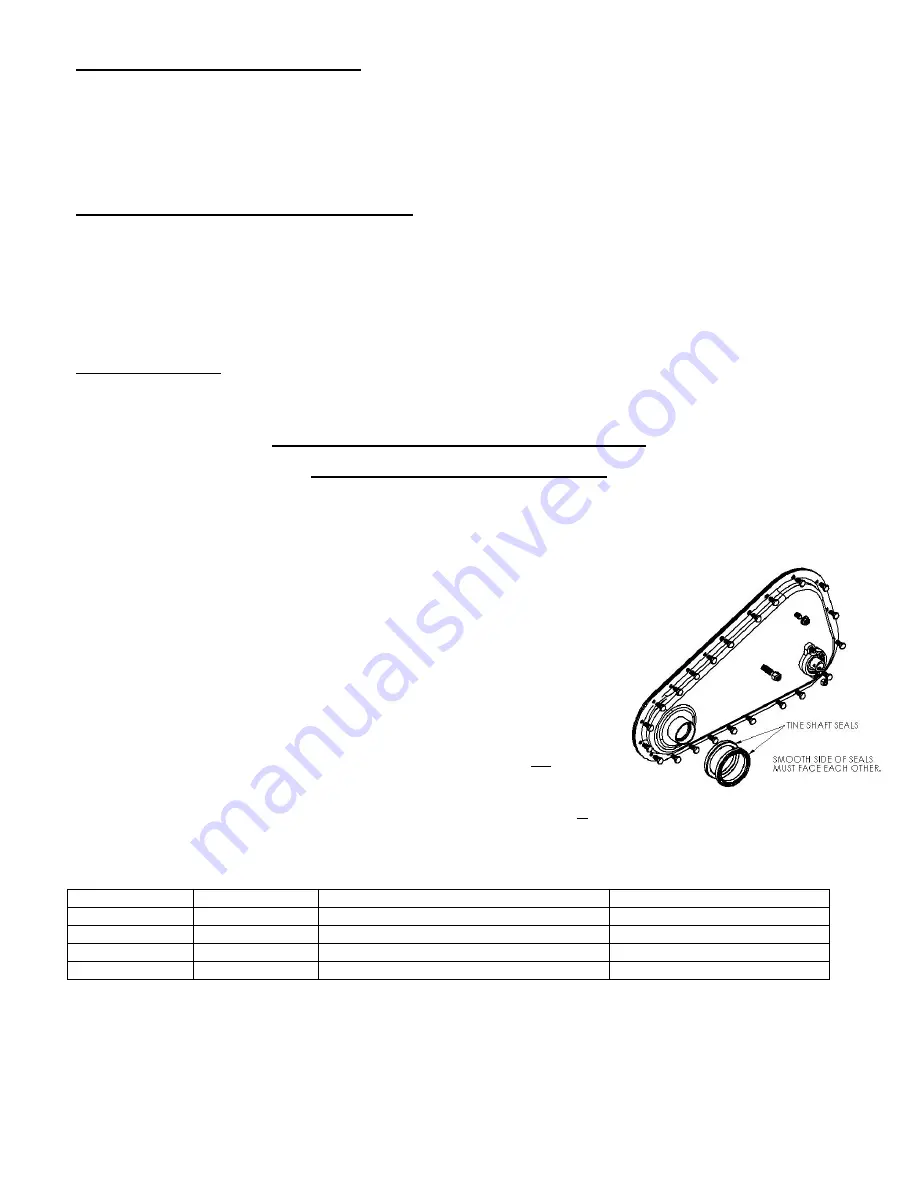

To replace the seals proceed as follows.

1. Take a screwdriver or awl and hammer along the tine shaft until you

can pry the first seal out.

2. Repeat and take the second seal out.

3. Place the new seal on the tine shaft with smooth side facing out, and

press into place. (Note: A 1 ½” ID piece of plastic pipe works great to

do this).

4. Place the second seal on the tine shaft with the smooth side facing in, and press into place.

5. Repeat to other side of the transmission.

Note: It is very important that the smooth side of the two seals be against each other.

Replacement Parts

PART #

QTY

WHERE USED

DESCRIPTION

706-0344

1

REAR TINE TILLER

OIL SEAL

706-0344-10

10

REAR TINE TILLER

OIL SEAL

– 10 PACK

706-0344-50

50

REAR TINE TILLER

OIL SEAL

– 50 PACK