KF139 Issue 17 © 2014

Page 2 of 12

4) Hold Flexigun and pump J3 handle. The Follower Rod

will slowly move out the end of the barrel because the

Follower is “locked” to the rod.

5) Stop pumping when groove in Follower Rod is visible.

Overfilling can cause grease to by-pass the follower.

6) Bleed air from grease (see Fig 5).

How To “Lock” the Follower

There is a slot in the front face plate of the Follower Assy.

The Follower Rod has a matching lug which allows the

Rod to be “locked” to the Follower so force can be applied

to the Follower to expel any air pockets in the grease.

To “lock” the Follower, align the Follower Rod lug and

Follower slot. Pull the Rod back then turn through 90 deg.

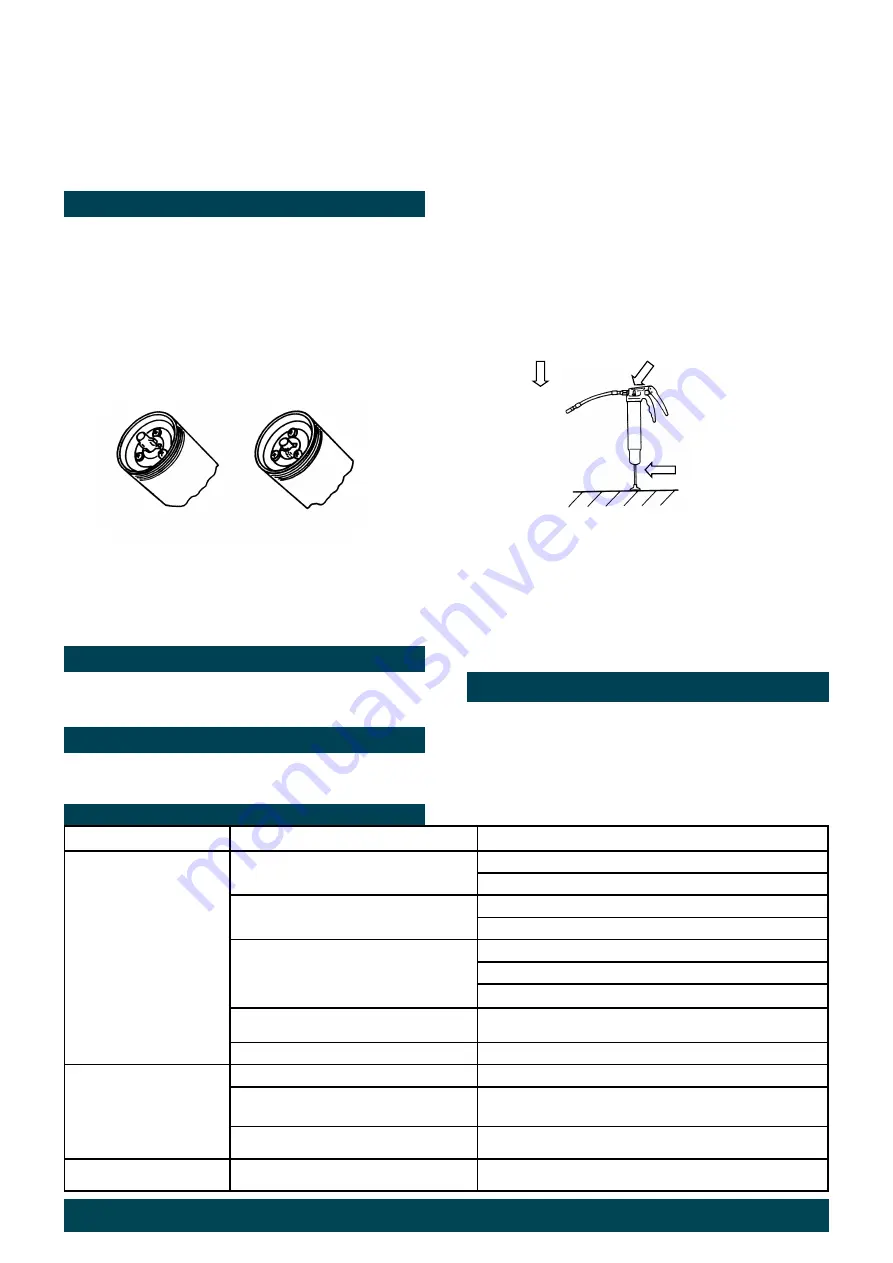

Fig 4

UNLOCKED LUGS LOCKED LUGS

PARRALLEL TO SLOT 90° TO SLOT

To “unlock” the Follower, gently push and turn the Follower

Rod. When the lug and slot are aligned, the Rod will be

free to move through the follower.

To Bleed Air From Grease

Normally there is no need to bleed air through the Filler/

Bleeder Valve. The gun will self bleed by pumping the

handle 5 to 10 times.

After each reload of grease:

1) Release the Follower Rod from the End Cap.

2) Gently push and turn the rod until it goes fully into the

barrel.

Pump the handle until grease appears at the coupler

(usually 5 to 10 times is sufficient).

If the grease is thick, cold or “tacky”, or an air-lock is

present, you will need to bleed the gun as follows:

Force air out through the Filler/Bleeder valve:

Important: Follower must be “locked” to rod ( see Fig 4).

1) Release Follower Rod From slot in end cap.

2) Unscrew the Filler/Bleeder Valve two full turns

(see Fig 5). Lock the Pull rod into the follower.

PUSH

FILLER BLEEDER

FOLLOWER ROD

Fig 5

3) Place the rod Pull Handle on a flat surface and push

gun down firmly (see Fig 5). Some grease will appear

before air is expelled.

4) Close the Filler/Bleeder Valve by hand, firmly.

5) Gently push and turn the Follower Rod until it goes

fully into the Barrel.

The Variable Stroke Feature

Your Flexigun is fitted with an extra Check Valve which

allows you to use shorter hand strokes for fast easy

greasing and to achieve higher pressures. The Handle

does not have to return all the way to its original position

before the next pumping stroke.

TROUBLE SHOOTING

How to Lock Follower

Rotate the follower to align the lugs to the slot in the follower

TROUBLE

CAUSE

REMEDY

1) Gun pumps little or no

grease.

a) Air lock – Follower stuck in cartridge.

1) Check condition of cartridge. Replace if

damaged.

2) “Lock” follower to rod (refer fig 4 ) and push

follower into cartridge.

b) Air lock – Grease too thick or cold.

1) Consult grease supplier.

2) Store grease gun and grease away from

extreme cold.

c) Check valve (10) ball seat damaged or dirty.

1) Remove check valve (10).

2) Clean and inspect all components. Replace as Required.

Important - use Loctite (or similar) thread sealant on

check valve threads.

d) Body outlet (6) ball seat dirty or damaged

Remove spring (3) and ball (4). Disassemble, clean, and inspect all

components.

Replace as required.

e) Worn or damaged Piston O-ring.

Remove handle (20), pull out plunger (13) and replace O-ring (12).

a) Follower (15) damaged or perished.

Replace follower (15).

b) Over filling gun when using filler pump

Stop pumping filler pump when groove on piston rod

i

s visible at the

back of barrel. Refer to filling instructions

c) Follower in wrong position for bulk

Grease.

If using bulk grease, Follower must be forward (Fig 1)

3) Unable to remove KY coupler

Coupler is a tight fit on the grease Nipple

Refer to the instruction on the “Notes” page

2) Grease leaks past

follower