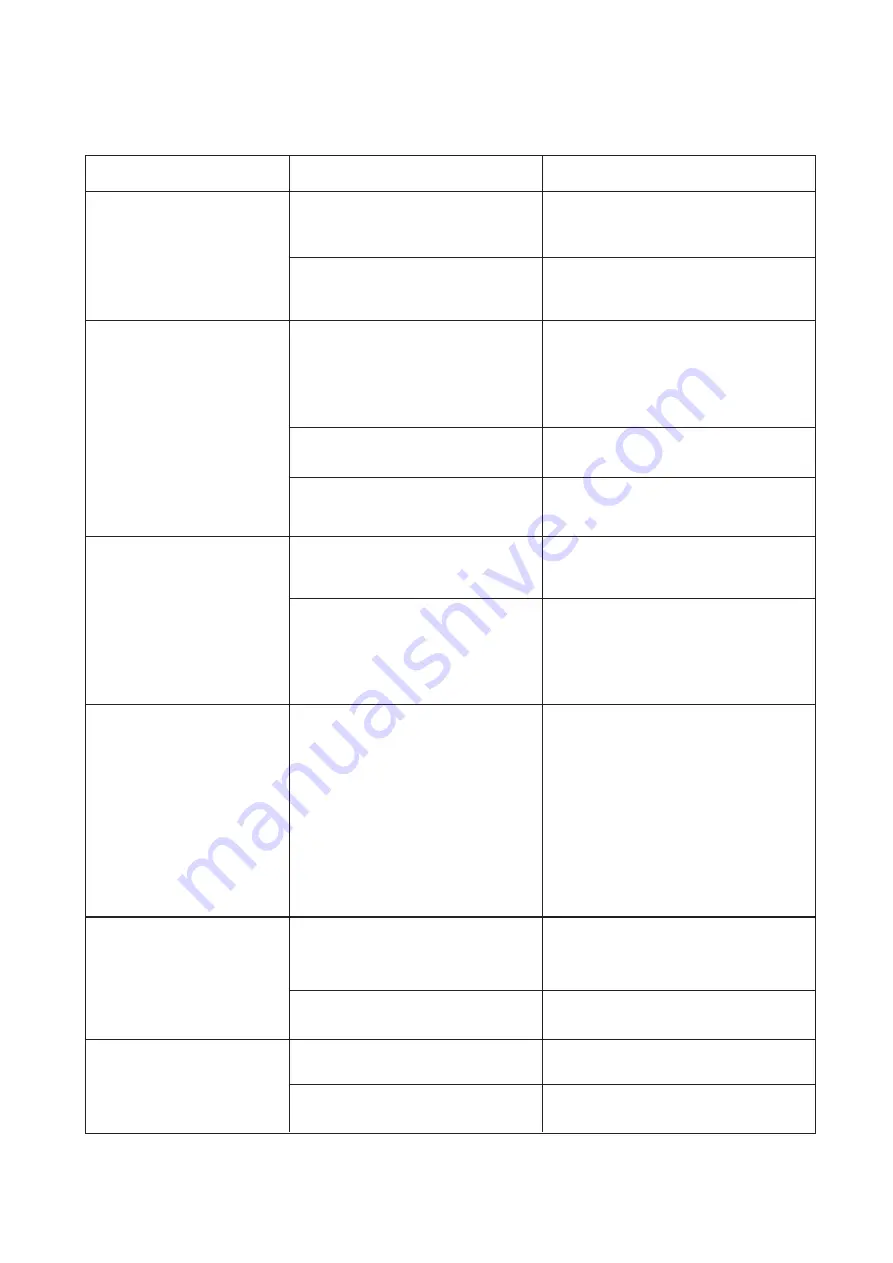

TROUBLE SHOOTING GUIDE

K6 PUMP UNIT

TROUBLE

CAUSE

REMEDY

The pump rod cap rises

slowly when not using the

gun.

( No visible leakages)

The rod cap springs up and

the unit will not pump grease.

The rod cap stays down, but

the unit will not pump grease.

Grease leaks at the top of the

clamp nut (7).

Grease leaks from the bottom

of the strainer cover (11).

Grease leaks from under the

clamp nut (7).

a) Dirt trapped between the inlet ball

(26) and the piston (10).

b) The piston o’ring (25) is defective

or worn.

a) Unscrew the clamp nut (7) and withdraw

the assembly. Clean the ball (26) and

piston (10) thoroughly. Reassemble.

b) Replace the piston o’ring (25).

a) Air lock in the grease caused by :-

i) Dent in the container stopping

the follower

.

ii) Damaged follower o’ring (21).

b) Grease container empty.

c) The footvalve assembly (19) is faulty,

holding the ball (18) off the seat.

a)

i) Remove the dents or tilt the follower

(20) under the dent.

ii) Replace the o’ring (21) in the

follower (20).

b) Change over to a new grease container

or refill the old container with grease.

c) Replace with a new footvalve assembly

(Do not attempt to rework this part).

a) The grade of grease is too Heavy.

b) The strainer (13) is blocked.

a) Use NLGI No2 grease, or lighter.

(Force out the old grease).

b) Unscrew the clamp nut (7) and withdraw

the assembly. Using a screwdriver, lever

off the strainer cover (11).Clean or replace

the strainer (13).

Gland o’ring (6) and back up washer

(5) are defective or worn.

Unscrew the clamp nut (7) and withdraw

the assembly. Hold the piston (10) and

loosen the nut (27), by pushing against the

spring (2) on the clamp nut (7), then carefully

undo the nut (27).

Replace the o’ring (6) and back up washer

(5). When re-assembling, support the

piston (10) when driving the pin (9) home.

Ensure that the flat end of the spring (2) fits

in the cap (1).

a) O’ring (14) damaged.

b) Spot welds broken.

a) Unscrew the clamp nut (7) and withdraw

the assembly. Using a screwdriver, lever

off the strainer cover (11). Replace o’ring

(14)

b) Replace the lid base (15).

a) Dirt under the clamp nut (7).

b) Damaged seal washer (8).

a) Undo and clean surfaces.

b) Replace seal washer (8).

5

Summary of Contents for MINI-LUBE K6

Page 7: ...NOTES 7...