3) Remove the lid from the grease container. This grease

pump is recommended for use with grease up to and

including NLGI No.2. Heavy grades of grease or cold

temperatures can result in operating difficulties.

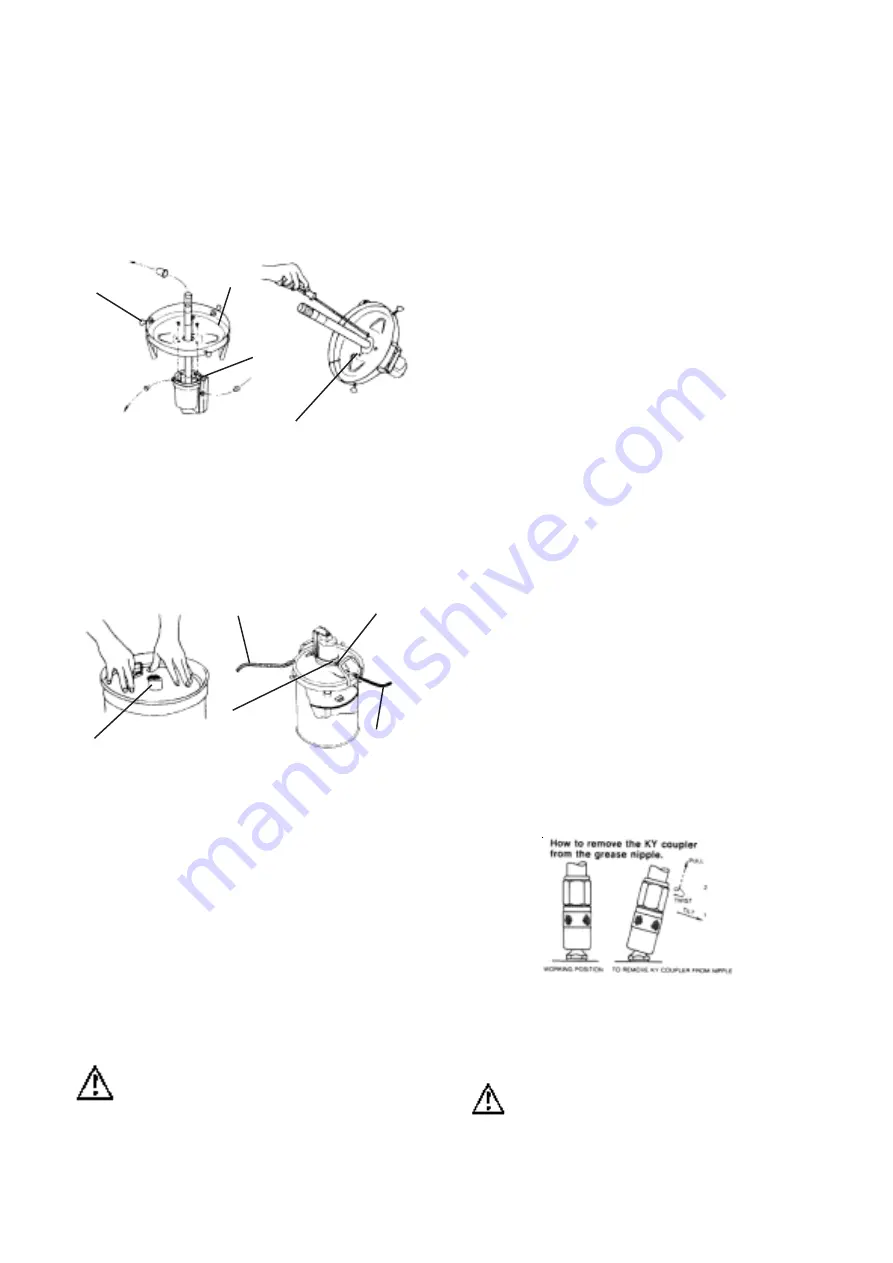

4) Place the follower plate in the grease container with the

follower handle and boss facing upwards (Fig 3). Push

the follower plate down onto the grease until some

grease is forced through the centre (boss) hole.

5) Insert the suction tube through the follower boss and

push the lid / pump assembly down until the lid sits

squarely on top of the grease container. Screw in the lid

positioning the thumb screws equally, until finger tight.

The lid must be centrally located on the grease container.

6) Apply thread tape or other thread sealant to both ends of

the high pressure grease hose. Pass the hose through

the lid assembly and screw the hose into the pump outlet

tightly ( fig 4). Screw the other end of the hose into the

ZSB swivel on the inlet of the B2 booster gun.

7) Before connecting the air supply the customer should

add a “stop” compressed air cock. The air cock must be

a ¼ turn type ( allowing quick closure) and should be

located close to the body of the pump and be easily

recognised. There is a wire mesh strainer located

inside the brass air inlet. It is recommended that a

micro- fine (5 micron) in line air filter be fitted to ensure

maximum efficiency of this pump. Then connect you

airline to the swivel type, brass air inlet.

CAUTION

It is important to read all warnings and operating

instructions before use.

8) Turn on your air supply and press the reset button

(fig 1). Hold the B2 booster gun near a waste container

(to collect the test grease) and squeeze the gun trigger.

The air motor will start to operate and the factory test

grease will appear followed by air (in high pressure

grease hose), followed by your grease. Tighten

connections as required.

(

Fig 1)

(Fig 2)

(Fig 3)

(Fig 4)

Follower Boss

3 Slotted 1/4”

BSW Screws

Thumb Screw

Lid

Reset Button

Remove plugs and

sleeves

Air-Line

Pump outlet

High Pressure

Grease Hose

Seal Condition

Hole (above

pump outlet)

OPERATION

1)

Before connecting the air supply check that all fittings

have been tightly fastened and all hoses are checked

for wear and or damage.

2)

Fully depress the reset button (fig 1), add air cock and

recommended air filter (as described in item ‘2’ of

assembly section) then connect the air supply. The

optimum pressure range is 550 to 700 kPa (80-

100psi / 5.5–7 bar).

3)

When air is connected to the pump and is turned on,

the air motor will start operating, this will allow grease

pressure to build, which pushes grease through the

pump and hose to the grease gun until ‘stall’ pressure

is reached,at this pressure the pump will stop.

For grease delivery press the trigger on the booster

gun. To stop grease delivery release the trigger on the

booster gun. When the trigger is released the grease

flow will stop and the pump will again build to ‘stall’

pressure and stop.

4)

To grease, connect the B2 booster gun coupler to the

grease nipple then squeeze the trigger. Normally, the

air motor will operate and grease will be pumped

through the nipple. If the grease nipple is blocked, the

air motor will stop (stall). If this happens do not

remove the gun from the nipple, just squeeze

the trigger on the B2 gun three or four times. The B2

booster gun has a boost facility which allows the

grease pressure delivered to the grease nipple to be

boosted and will clear most blocked nipples.

Note: The B2 booster gun creates the extra pressure and

not the pump.

5)

Remove the coupler from the grease nipple by first

tilting (to release any pressure) then a twist and pull

motion. Loosen the black coupler cap if difficult to

remove.

CAUTION

Use the lid handles to move the greasing unit. Do not

move the pump by pulling the air or grease hose.

(Fig 5)

2