I

I

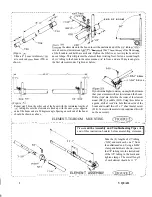

E N D O F B O O M

I

I

I

I

I

(Figure

. .

tubing

.

. . .

- - -

the elements onto the boom, insert the unslotted end of the

(Figure

into a boom-to-element mount

Y).

Now

tnis

I

tne

or tne Doom

a U-bolt, saddle,, and hardware as shown. Tighten the U-bolt so as to crimp the boom into

Slide a 4” boom reinforcer

an oval shape. This will prevent the element from twisting. Next, fasten a second length

,

mto each end

boom (T28) as

of

tubing to the boom in the same manner,

in from, and at a 90 degree angle to

shown.

the first element mount. Tighten as before.

I

(Figure

Repeat step 2B on the other end of the boom with the remaining lengths of

tubing. Be sure the elements are lined up with the ones

opposite

end of the boom and at a 90 degrees angle. Spacing on each end of the boom

should be shown as above.

I

I

D R I L L I

I

- 1

D R I L L

I

Ifyouliveinahighwindareayoumayfurtherinsure

that your elements will not twist around the boom.

Drill a

dia. hole thru the center of the element

mount (BE

saddle (SO2). Using these holes as

a guide, drill a 1

dia. hole thru one side of the

boom and install the

x 1” sheet metal screw

(S3 0). In areas with normal wind conditions this will

not be necessary.

I

I

I

ELEMENT-TO-BOOM MOUNTING

----

- - - - - - - -

---- ----

I

\

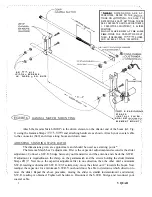

Please

read the Assembly and Troubleshooting Tips

at the

end of this instruction booklet before assembling elements.

i

1 1

‘-9”

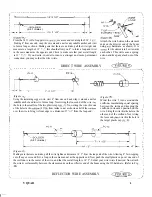

Take the (4) lengths of

tubing

and mark each one 3” from

I

I

the unflattened end. Using a

clamp and hardware shown, insert

I

the

tubing into the slotted end

of the

tubing to the mark and

tighten clamps. The overall length

I

of each element should be 11’ 9”.

I

I

I

I

I

I

I

I

I

I

ELEMENT ASSEMBLY

- - - - - - - - - - - - - - - - _ _ - _ - - - - - - - - - - - - - - - - - - - - - - - - - - -

3

V QUAD