I

( O P T I O N A L )

7

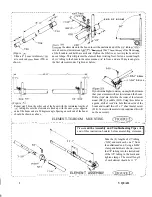

From the 34 ft. roll of copper wire

measure and cut a length of 14’ 3

,

Starting 4” from one end, wrap the wire around a nail or any suitable anchor and twist

I

to form a loop as shown. Making sure that there are no kinks, pull the wire tight and

measure to a length of 13’ 7

this should allow you 4” to form a loop and twist

in the same manner as the opposite end. Check to make sure that your overall length

I

I

I

I

I

I

I

s21

Attach the wire between the element

ends on the director end of the boom

,

I

is 13’ 7

If you desire, in order to insure a stronger and more permanent

I

I

connection, you may solder the wire twists.

using

hardware as shown. It is

for the elements to bow towards

I

each other. This will cause a spring

action and keep any slack out of the

wire.

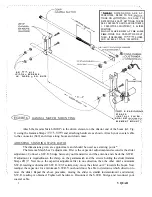

DIRECT WIRE ASSEMBLY

- - - - - - - - - - - - - - - - - - - - - _ _ _ _ _ _ _ _ _ _ _ _ _

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

P

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

(Figure

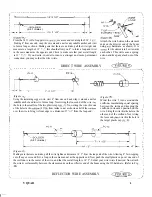

Using the remaining copper wire, start 4” from one end and wrap it around a nail or

suitable anchor and twist to form a loop. Next string the loose end of the wire

the hole in the smaller of the two plastic caps

1). Now string the wire thru one

of the holes in the

(FO

from inside to out as shown and slid the

over the wire to bring its front edge to a distance of 7’

from the loop end.

( O P T I O N A L )

(Figure

Making sure there are no kinks, pull the wire tighten and measure 14’ 3”

the loop end of the wire. Allowing 4” for wrapping,

cut off any excess and

a loop in the same manner as the opposite end. Now push the small plastic cap over one end of

the coilfonn is in the center of the wire, and that the overall length is 14’ 3”. Solder your wire twists if desired. Now attach

the wire coil assembly between the element ends on thee

end of the boom using the

hardware. (Refer to Fig.

REFLECTOR WIRE ASSEMBLY

(Figure

Wind the wire 3 turns around the

coilfonn, maintaining equal spacing

between the turns and keeping the

coilfonn in its same position on the

wire. String the wire thru the hole in the

other end of the coilfonn. Next string

the loose end

wire thru the hole in

the larger plastic cap

0).

V QUAD

4