© 2015 MacroAir Technologies Toll Free: 866 668 3247 Fax: 909 890 2313 www.macroairfans.com 13

Rev. Date 090415

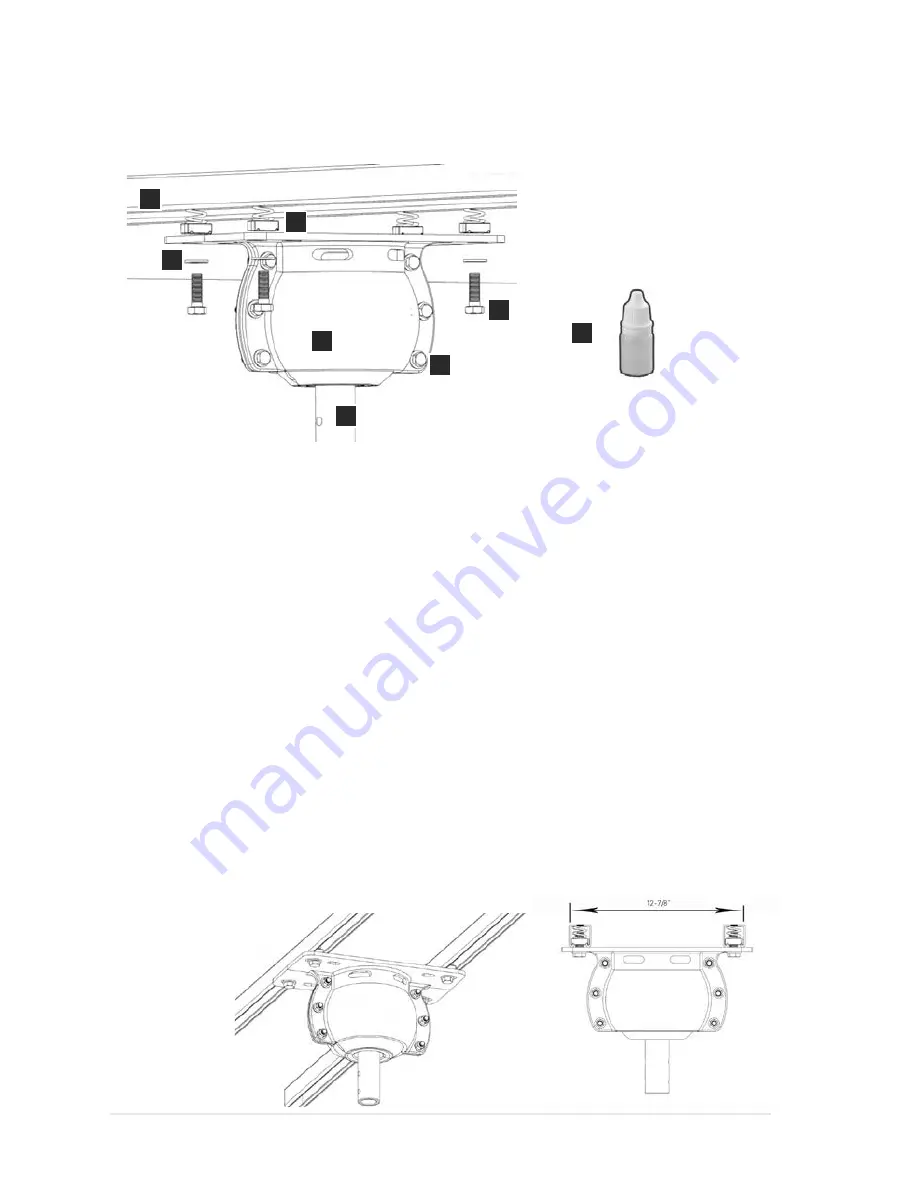

Components:

A - 1/2”-13 x 1” Grade 5 Bolts (4)

B - 1/2’’ Flat Washers

C - 1/2”-13 Unistrut Spring Nuts (P1010) (4)

D - Liquid Thread Lock

E - Rapid Mount Industrial

F - 1-5/8” Unistrut Unpierced Channels (P1000 or P1001B) (2)

G - Locking Hardware (Locking Hardware is left loose from factory. Do not remove prior to

installation.)

H - Drop Length Attachment Point

This method is used to span components of a building structure. The attachment point to the

building structure can vary greatly and we recommend Unistrut be contacted so they may

recommend the best method to attach the Unistrut to the building (www.unistrut.us). If the

spanning distance is greater than 6 feet (P1000) or 10 feet (P1001B), please consult a Structural

Engineer. Please refer to page 3

for the maximum torque and weight for both Model 550 and 780.

1.1.1A:

Span two pieces of 1-5/8” Unistrut open side facing down and space apart so there is

12-7/8” from outside edge to outside edge (See illustration for example).

1.1.2A:

Once the Unistrut is in place, apply liquid thread lock to the recommended bolts and use

the remaining recommended hardware to attach the mount to the Unistrut. Torque the bolts to

50ft-lbs. Recommended torque is based on 1/2-13’’ hardware.

1.1.3A:

Tighten the locking hardware on the rapid mount to 30 ft-lbs once the drop length

attachment point is level.

Final Results:

1.1A Unistrut Span Mounting

A

B

C

D

E

F

H

G

NOTE: Mounting to Z-purlins requires span mounting. Mounting to trusses requires two or

more trusses to be linked with Unistrut or angle iron.