Macurco RD-xx User Manual

REV – 2.1

[34-2900-0511-7 ]

22

|

P a g e

5.2

Sensor Poisons

The gas sensor in the detector is designed with extreme sensitivity to the environment. Alcohols, ammonia, cleaning solvents,

paint thinner, gasoline vapors, and aerosol propellants may cause nuisance alarms.

In addition, the sensing function may be deteriorated if it is exposed to a direct spray from aerosols such as paints, silicone

vapors, etc., or to a high density of corrosive gases (such as hydrogen sulfide or sulfur dioxide) for an extended period of time.

•

Avoid contamination by alkaline metals. Sensor characteristics may be significantly changed if the sensor is

contaminated by alkaline metals, especially salt-water spray.

•

Sensor performance may be affected if exposed to a high density of reactive gases for a long period of time, regardless

of the powering condition.

•

If water freezes on the sensing element surface, the sensing material may crack, which will irreversibly affect sensor

characteristics.

•

If water condenses on the sensor element surface and remains for an extended period, sensor characteristics may

temporarily drift. Light condensation under normal conditions of indoor usage would not pose a significant problem for

sensor performance.

•

Regardless of its powering condition, if the sensor is exposed in extreme conditions such as very high humidity, high

temperatures, or high contamination levels of organic vapors or other gases for a long period of time, sensor

performance may be impaired.

•

Sensors cannot properly operate in a zero or low oxygen content atmosphere. They require the presence of normal

ambient oxygen in their operating environment in order to function properly.

•

Sensor characteristics may be changed due to soaking or splashing the sensor with water.

•

Avoid mechanical shock. Breakage of lead wires may occur if the sensor is subjected to a strong shock.

5.3

End-of-Life Signal

The RD-xx has a long life, non-replaceable solid-state sensor. Seven (7) years after the RD-xx is installed the sensor end-of-life

signal will be activated indicating that the RD-xx has reached the end of its typical usable life. The end-of-life signal will cause an

error code t200 “Sensor expired”. See Error Codes section. The end-of-life signal can be silenced for 48 hours by pressing the

"ENTER/TEST" button or by temporarily dropping power to the unit. The end-of-life signal provides the user an opportunity to

test the sensor assuring that it is still performing within acceptable parameters through the sensor is nearing the end of its

expected life. The silence function will continue to be available for 29 days after the RD-xx initiates the initial end-of-life signal.

After this 29-day period, the RD-xx can no longer be silenced, and the sensor life must be reset, or the RD-xx detector replaced.

6

Maintenance

The RD-xx is low maintenance. The unit uses a long-life solid-state sensor that has a 7+ year life expectancy (in normal

conditions). The detector’s performance should be tested regularly by using gas as detailed in the Gas Testing section. All

maintenance and repair of products manufactured by Macurco are to be performed at the appropriate Macurco manufacturing

facility. Macurco does not sanction any third-party repair facilities.

6.1

Sensor Life Reset

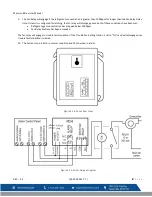

1.

Remove the Philips screw on the front of the RD-xx. Pull the front cover of the unit off.

2.

To reset the sensor life (rSt), from normal or warm-up mode, press the Next button four times to get to “SEn” or Sensor

Mode.

3.

Then press the Enter button to get to “rSt” - Reset Sensor Mode.

4.

Press the Enter button again to see the sensor reset status. If the sensor life has already been reset, done “don” will be

displayed. If it has not already been reset, “nO” will be displayed. Push Next to change it to “ yES” (flashing) then push

Enter to confirm the change (solid) and push Enter again to return to "rSt” in the “SEn” menu. Push Next until “End” is

displayed then push Enter to get back to normal operation.