15

IT

EN

FR

ES

Madas Technical Manual

- REV. 0 of 10

th

May 2018

RG/2MC - FRG/2MC

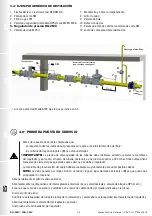

Filter element guides

Filter element guides

The filter element must be

placed inside these guides

The filter element must be

placed inside these guides

fig. a:

DN 15 ÷ DN 50 cover without bottom cover

fig. b:

DN 65 ÷ DN 100 cover without bottom cover

5.0 - MAINTENANCE

• Before carrying out any dismantling operation on the device, make sure that there is no pressurised gas inside.

Check the condition of the filtering element (21) as follows

• Loosen the fastening screws (

17

) and very carefully remove the bottom cover (

16

) from the body (

11

);

• Extract the filter element and check its conditions. Blow it and clean it and, if necessary, replace it (see figures “a” and “b”

below for the positioning);

• Check the conditions of the sealing O-Ring of the bottom cover (

16

) and replace if necessary;

• Make sure the sealing O-Ring (

18

) of the bottom cover (

16

) is inside the relevant groove before putting it back on;

• Reassemble the bottom cover (

16

) and secure it in its original position, being very careful not to “pinch” or damage the

O-ring

during

tightening.

IMPORTANT:

1. for DN 15 ÷ DN 50 connections make sure that the centre pin (

10

) is centred in the guide of the bottom cover (

16

);

2. for DN 65 - DN 80 - DN 100 connections pay attention to the Teflon split ring (

14

): when reassembling the bottom

cover (

16

) it must be placed inside the specific guide (as shown in figure 6);

• Tighten the screws gradually, following a “cross” pattern, until the torque (tolerance -15%) indicated in table 2 on page 41

is reached. Use a calibrated torque wrench to do this.

• Check the body/cover seal;

NOTE

: for internal inspections, it is recommended to:

• Also check the obturator’s integrity and, if necessary, replace the rubber seal (

15

);

• Replace the seals before reassembling.

• It is recommended to contact the Technical Department to check or replace the membranes.