13

IT

EN

FR

ES

M16/RM N.C. EEX

Madas Technical Manual

- 2|2.2b - REV. 0 of 10

th

May 2018

1

2

3

4

5

6

7

8

9

piping

application

discharge in

open air

internal thermal unit

ZONE 1

external roof

10

discharge in

open air

discharge in

open air

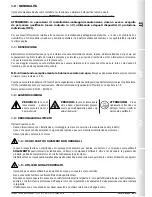

3.4 - GENERIC EXAMPLE OF INSTALLATION

1. SM jerk ON/OFF valve

2. FM gas filter

3. M16/RM N.C. Manual reset solenoid valve EEX

4. OPSO series MVB/1 MAX shut off valve

5. RG/2MC pressure regulator

6. MVS/1 relief valve

7. Pressure gauge and relative button

8. Gas detector

9. SM remote jerk ON/OFF valve lever control

10. Compensation/Vibration damping joint

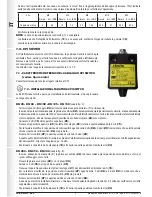

4.0 - MANUAL RESET

To reset the solenoid valve:

• Make sure the power supply is connected;

• Close the flow downstream of the solenoid valve in order to balance the pressure between upstream and downstream when

opening.

• DN 65 - DN 80 - DN 100 - DN 125 - DN 150

without CPI (see fig. 1):

• Loosen completely and remove the protective cover (

13

);

• Loosen the reset pin (

14

) from the fastening screw (

15

);

• Insert the non-threaded part of the reset pin (

14

) in the hole provided on the hex knob (

1

);

• Using the pin (

14

):

• Turn the reset knob (

1

) slightly clockwise and wait a few seconds for the pressure upstream and downstream of the

valve to stabilise;

• After balancing the pressure, turn the reset knob (

1

) clockwise to its stroke end, when it is coupled;

• Remove the pin (

14

) from the knob (

1

) and screw it on in its original position. Alternatively to the reset pin (

14

), it is

possible to use a size 32 commercial spanner to turn the reset knob (

1

);

• Screw the protective cover (

13

) back on in its original place. Or seal it in that position.

• DN 200 - DN 250 - DN 300

without CPI (see fig. 2):

• Loosen completely and remove the protective cover (

13

);

• Using a size 32 commercial spanner:

• Turn the reset knob (

1

) slightly clockwise and wait a few seconds for the pressure upstream and downstream of the

valve to stabilise;

• After balancing the pressure, turn the reset knob (

1

) clockwise to its stroke end, when it is coupled;

• Remove the commercial spanner from the knob (

1

), then tighten the protective cover (

13

) back into its original position.

Or seal it in that position.

• DN 65 - DN 80 - DN 100 - DN 125 - DN 150 - DN 200 - DN 250 - DN 300

with CPI (see fig. 3 and 4):

• Loosen the fastening screw (

23

) and remove the protective cover (

13

);

• Using a size 32 commercial spanner:

• Turn the reset knob (

1

) slightly clockwise and wait a few seconds for the pressure upstream and downstream of the

valve to stabilise;

• After balancing the pressure, turn the reset knob (

1

) clockwise to its stroke end, when it is coupled;

• Remove the commercial spanner from the knob (

1

);

• Screw the protective cover (

13

) back on in its original place and secure it with the screw (

23

). Or seal the cover in that

position.