12

M16/RMOX N.A. - M16/RMOCX N.A.

Madas Technical Manual

- 3|3.1bX - REV. 0 of 1t

h

Aug 2019

ES

FR

EN

IT

1

2

8

9

10

3

4

5

6

7

7

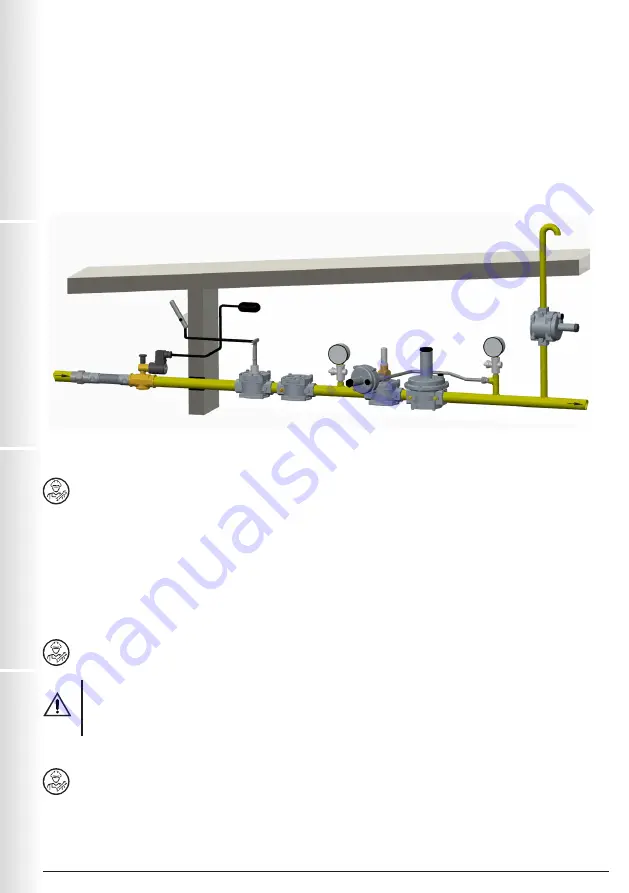

3.4 - GENERIC EXAMPLE OF AN INSTALLATION

1. M16/RMOX N.A. Manual reset solenoid valve

2. SM jerk ON/OFF valve

3. FM gas filter

4. OPSO series MVB/1 MAX shut off valve

5. RG/2MC pressure regulator

6. MVSP/1 relief valve

7. Pressure gauge and relative button

8. Gas detector

9. SM remote jerk ON/OFF valve lever control

10. Expansion joint/anti-vibration mount

discharge

in open air

internal thermal unit

external roof

piping

application

The subsequent application of a non-conductive coating with a thickness of > 0.2mm on the external surface prohibits its use

in environments with potentially explosive atmospheres where group IIC Gases are present. The thickness of the coating must

be < 2mm for group IIB.

For group III it is necessary to take appropriate precautions to prevent the accumulation of electrostatic charges (e.g. cleaning

with an antistatic cloth, etc.).

4.0 - MANUAL RESET

To reset the solenoid valve:

• Make sure the valve is

NOT

electrically powered;

• Close the flow downstream of the solenoid valve in order to balance the pressure between upstream and downstream when opening;

• Push the reset handgrip (

1

) and wait a few seconds for the pressure upstream and downstream of the valve to stabilise;

• After balancing the pressures, pull the reset knob (

1

) until it connects.

• To close maually the solenoid valve (only M16/RMOCX N.A. versions), push the closing push button (

12

).

• The red label under the manual reset (

1

), if visible, shows that the valve is closed.

5.0 - FIRST START-UP

• Before start-up make sure that all of the instructions on the rating plate, including the direction of flow, are observed;

• After having gradually pressurized the system, check the seal and operation of the solenoid valve, electrically

powering / disconnecting it.

IMPORTANT NOTE

: Do not use the connector as a switch to close the solenoid valve.

• Make sure the solenoid valve is closed by electrically connecting it.

5.1 - RECOMMENDED PERIODIC CHECKS

• Check tightness of the flanged/threaded connections on the system;

• Check tightness and operation of the solenoid valve;

• Clean the product regularly to prevent dust from building up;