12

ES

FR

EN

IT

Madas Technical Manual

- REV. 0 of 10

th

May 2018

RG/2M - FRG/2M

3.2 - INSTALLATION

(see example in 3.4)

Threaded devices:

• Assemble the device by screwing it, with the due seals, onto the plant with pipes and/or fittings whose threads are consistent

with the connection being attached.

• Do not use the neck of the top cover (

4

) as a lever to help you screw it on, only use the specific tool;

• The arrow, shown on the body (

11

) of the device, needs to be pointing towards the application;

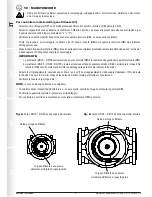

Flanged devices:

• Assemble the device by flanging it, with the due seals, onto the plant with pipes whose flanges are consistent with the

connection being attached. The gaskets must be free from defects and must be centred between the flanges;

• If, after installing the gaskets, there is still an excessive space in between, do not try to reduce the said gap by excessively

tightening the bolts of the device;

• The arrow, shown on the body (

11

) of the device, needs to be pointing towards the application;

• Insert the relative washers inside the bolts in order to prevent damage to the flanges during tightening;

• When tightening, be careful not to “pinch” or damage the gasket;

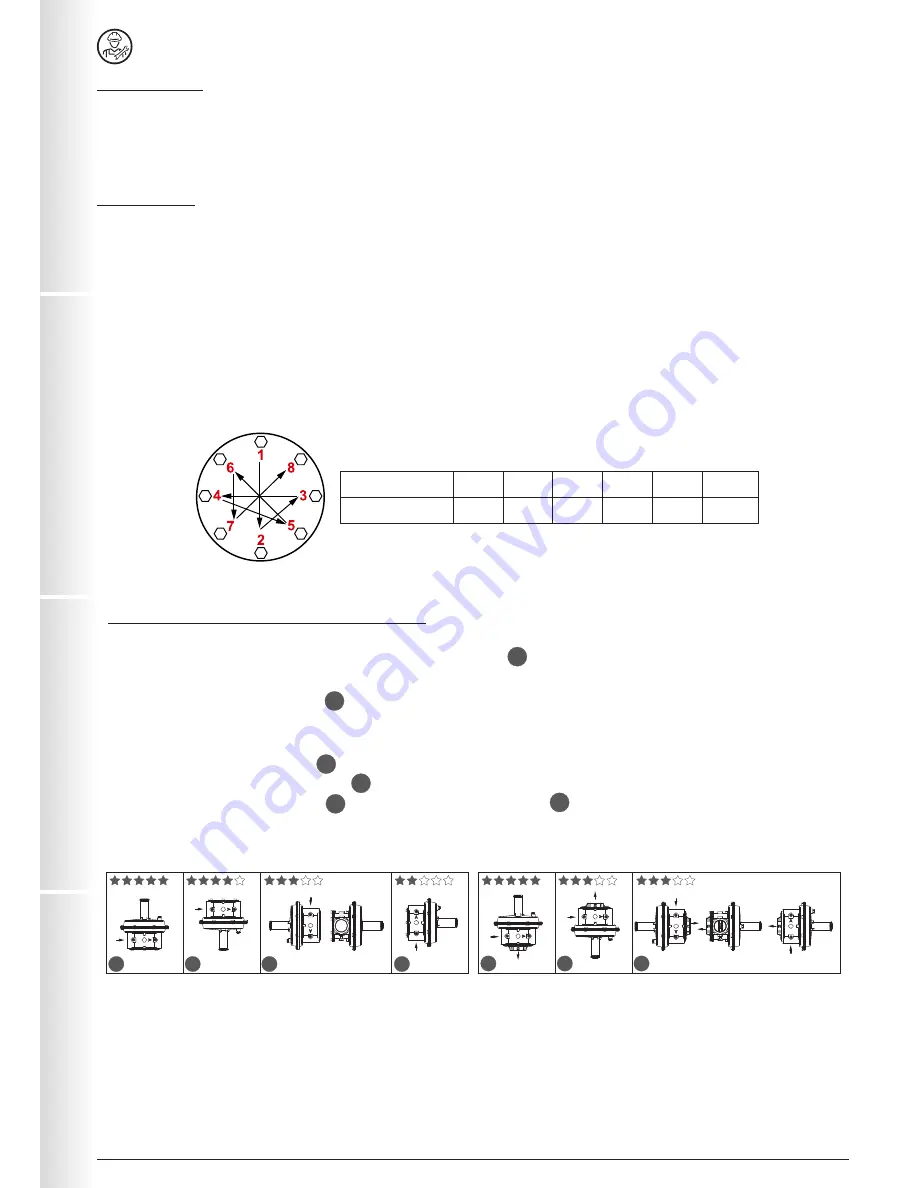

• Tighten the nuts or bolts gradually, in a “cross” pattern (see the example below);

• Tighten them, first by 30%, then by 60% and finally 100% of the maximum torque (see the table below according to

EN 13611);

Diameter

DN 32 DN 40 DN 50 DN 65 DN 80 DN 100

Max. torque (N.m)

50

50

50

50

50

80

• Tighten each nut and bolt again clockwise at least once, until the maximum torque has been achieved uniformly;

• Common procedures (threaded and flanged devices):

• The regulator is normally positioned before the utility. Primarily evaluate the possibility of installing the regulator as shown in

the installation example in 3.4, namely in an optimal position pos.

a

(see figures below);

• Should this not be possible, the following factors must be considered:

1. if installed as shown in pos.

b

the maximum P2 value declared on the rating plate could be less by a few mbar.

NOTE:

for versions with 90° connections, it is recommended to install a filter after the regulator that protects it from

debris that could enter from downstream from above (due to gravity);

2. if installed as shown in pos.

c

the life span of the product could be shorter than the duration that could be obtained

if installed in the optimal position

a

;

3. if installed as shown in pos.

d

, besides that indicated for pos.

c

it is recommended to install a filter after the

regulator that protects it from debris that could enter from downstream from above (due to gravity);

Connections in line 90° connections (closed line output)

a

b

d

c

a

b

c

• During installation, avoid debris or metal residues from getting into the device;

• To guarantee mechanical tension-free assembly, we recommend using compensating joints, which also adjust to the pipe’s

thermal expansion;

• If the device is to be installed in a ramp, it is the installer’s responsibility to provide suitable supports or correctly sized

supports, to properly hold and secure the assembly. Never, for any reason whatsoever, leave the weight of the ramp only on

the connections (threaded or flanged) of the individual devices;

• In any case, after the installation check the tightness of the system, avoiding to subject the membrane of the regulator

(therefore, the downstream pipe section) to a pressure higher than 300 mbar;