IT

EN

FR

ES

17

Madas Technical Manual

- 5|5.2a - REV. 0 of

th

Apr 2019

RG/2MCS - RG/2MBZ

6.0

SETTING

Before carrying out the operations, make sure that the supplied spring/s is/are suitable for the desired Pa - OPSO - UPSO and

differential relief valve fields.

6.1 - Adjusting the maximum pressure shut off (OPSO)

• Unscrew the cap (

11

);

• Use the supplied key (

32

) to fully tighten the adjustment ring nut of the maximum shut off (

28

);

• Start the system, reset the shut off device as indicated in 4.0 and make sure that there is no gas consumption (close the

applications downstream of the regulator);

Method 1:

1. Loosen and remove caps (

26

) and (

11

);

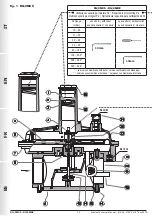

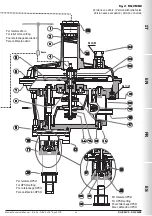

2. Use an 8 mm socket wrench (see fig. 1a and 2a) to press on the nut (

4

), slowly increasing the downstream pressure

to the desired value and simultaneously keep the nut (

4

) pressed; use the key supplied (

32

) to loosen the ring nut

(

28

) until the device is triggered;

3. Tighten the caps back to their original position and repeat the Pa setting steps;

Method 2:

1. Alternatively, use an auxiliary gas pressure to slowly increase the downstream pressure to the desired value and

simultaneously, use the key supplied (

32

) to loosen the ring nut (

28

) until the device is triggered (so as to avoid

having to set the Pa again);

• In both cases, reset the system by following the correct procedure and verify that the trigger value is that desired by repeating

the release step 2-3 times;

• If necessary, adjust the trigger value by turning the ring nut (

28

) with the specific key (

32

).

6.2 - Adjusting the minimum pressure shut off (UPSO)

• Unscrew the cap (

11

);

• Use the key supplied (

32

) to loosen the adjustment ring nut of the minimum shut off (

30

) to the minimum;

• Start the system and reset the shut off device as described in 4.0;

• Reduce the downstream pressure to the desired trigger value;

• Use the key supplied (

32

) to tighten the adjustment ring nut (

30

) until the minimum pressure shut off is triggered.

• Reset the system by following the correct procedure and verify that the trigger value is that desired by repeating the release

step 2-3 times;

• If necessary, adjust the trigger value by turning the ring nut (

30

) with the specific key (

32

);

6.3 - Adjusting the relief valve (differential DfRv)

NOTE

: The relief valve (if any) in these regulators is differential, therefore the range value (DfRv) indicated must be added to

the range value of the outlet pressure (Pa).

Example: Pa=32

-

60 mbar - DfRv=15

-

40 mbar.

Means that the relief valve can be calibrated from: (Pa min + DfRv min) = 32+15=47 mbar to: (Pa max + DfRv max) =

60+40=100 mbar

Therefore the effective range of the relief valve (in this case) is 47

-

100 mbar.

• Start the system and set the shut off as described in point 4.0;

• Slowly close the valve downstream of the regulator;

• Loosen and remove the cap (

26

);

• Use the 8 mm socket spanner (see fig. 1 and 2) to fully tighten the nut (

4

);

• Use the 8 mm socket spanner to press the adjustment nut (

4

) and increase the pressure Pa, reading it on the pressure gauge,

up to the desired setting value;

• Without pressing further, slowly loosen the adjustment nut (

4

) until the pressure Pa begins to decrease, shown on the

pressure gauge;

• In this case, the relief valve is set to the desired value;

• Remove the socket spanner and close the cap (

26

).