ES

FR

EN

IT

18

Madas Technical Manual

- 5|5.2a - REV. 0 of

th

Apr 2019

RG/2MCS - RG/2MBZ

6.4 - Adjusting the outlet pressure (Pa)

The outlet pressure Pa (unless specifically requested) is factory-set with the regulator installed as indicated in 3.4 and with

the adjustment screw (

1

) set approximately at the minimum setting value. The safety shut offs/relief valve are set accordingly;

If the regulator is installed in different positions, check and reset the outlet pressure Pa, and consequently the devices

incorporated in the regulator;

Adjust the outlet pressure as follows:

• Unscrew the cap (

26

);

• Unscrew the adjustment screw (

1

) and set it to the minimum setting allowed (threaded end of the top cover (

25

));

• Start the system or make sure there is a minimum flow downstream of the regulator;

• To increase the pressure calibration downstream of the regulator, tighten the adjustment screw (

1

) to the desired value.

Perform the reading with a calibrated pressure gauge, installed downstream of the regulator to at least 5 DN (see examples

in 3.4);

• Screw the cap (

26

) back on and if necessary, seal it in that position using the appropriate seal holes (if any);

• Use pressure outlets (

19

)on the device only for zero flow or very low flow measurements.

7.0 - RECOMMENDED PERIODIC CHECKS

• Use a suitable calibrated tool to ensure that the bolts are tightened as indicated in 3.2;

• Check the tightness of the flanged/threaded connections on the system;

• Check the tightness and operation of the regulator/shut off/relief valve;

The final user or installer is responsible for defining the frequency of these checks based on the severity of the service conditions.

7.1 - CHECK THAT THE MAXIMUM PRESSURE SHUT OFF VALVE IS WORKING (OPSO)

Reset the shut off device and close the valve downstream of the regulator;

Method 1:

1. Loosen and remove caps (

26

) and (

11

);

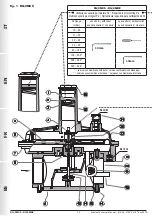

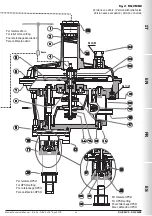

2. Use the same tool (shown in fig. 1 and 2) to press the nut (

4

) and slowly increase the downstream pressure until the

device is triggered;

3. Tighten the caps back to their original position and repeat the Pa setting steps (6.4);

Method 2:

1. Alternatively, use an auxiliary gas pressure to slowly increase the downstream pressure until the device is triggered

(so as to avoid having to set the Pa again).

7.2 - CHECK THAT THE MINIMUM PRESSURE SHUT OFF VALVE IS WORKING (UPSO)

• Reset the shut off device and close the ball valve upstream of the regulator;

• open the relief valve, downstream of the device, partially and slowly. As the outlet pressure decreases slowly it will cause the

minimum shut off to trigger at its setting value;

• Repeat the trigger step 2-3 times to make sure that the system functions correctly. Between one trigger and another, set the

downstream pressure back to the setting value.

7.3 - CHECK THE TIGHTNESS OF THE DEVICES (OPSO AND UPSO)

• Fully empty the downstream pipe section (wait a few seconds to allow it to empty completely). The downstream pressure

must remain at zero when the relief valve is closed.