2 ©2006

MadCow

Rocketry™

MIM-23A

Hawk

Assembly

Please make sure you read all directions and understand how to assemble your model

before you start construction. It is also a good idea to test fit each part before assembly

– some manufacturing tolerances may require light sanding before final assembly.

Laser cut parts will exhibit varying amounts of charring on the edges depending on the

density of the plywood. The charred edges do not interfere with bonding and do not

need to be cleaned before assembly. In most cases the charring will be cleaned up

during sanding for finishing and painting.

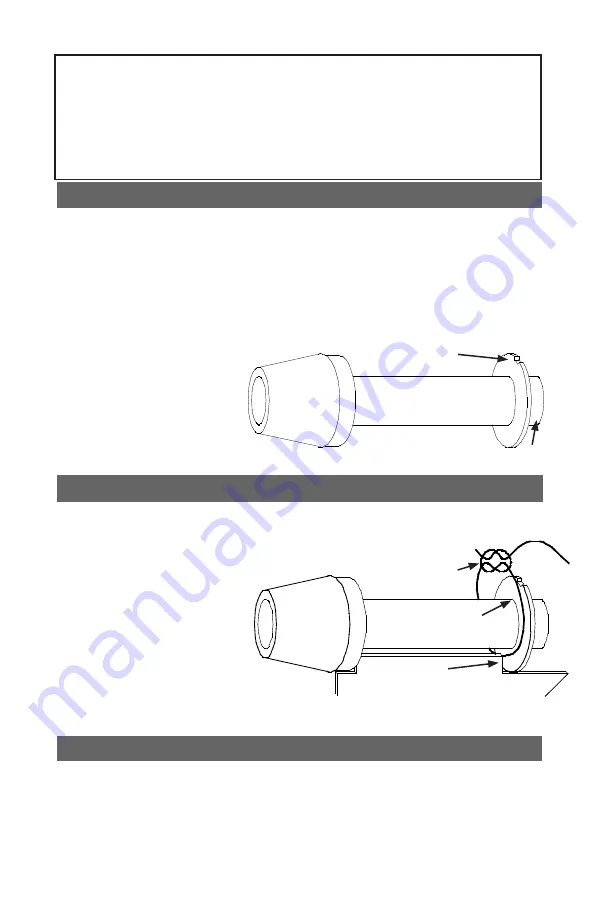

Step 1 – Motor Mount Assembly

Test fit the tail cone into the aft end of the body tube. Make sure that the tail cone

shoulder does not interfere with the fin slot. If it does, sand the shoulder to the correct

length (the nominal length of the shoulder should be 0.5”). Next, Test fit the tail cone

and centering ring over the motor mount tube and sand if necessary. The centering ring

should have a snug fit but loose enough to move the ring over the motor tube without

deforming it. Also test fit the centering ring in the body tube and sand if necessary.

Spread some epoxy on the outside of one end of the motor tube and slide the tail cone

in place so the motor tube is flush with the aft end of the tail cone. Make sure you clean

the motor tube of any epoxy so

as not to interfere with the fin

tangs later.

After the tail cone is dry, make a

mark 3/8” from the other end of

the motor tube. Spread some

epoxy on the motor tube and

slide the forward ring (with the notch) until it aligns with the mark.

3/8” Exposed

Forward Ring Notch

Step 2 – Shock Cord Attachment

The shock cord in this kit consists of a shorter section of Kevlar and a longer section

of nylon cording. The two sections should be tied together using a single overhand,

ring bend or double fisherman’s knot. The Kevlar section will be attached to the motor

mount and the nylon section will be

attached to the nose cone.

Wrap the end of the Kevlar shock

cord around the forward end of the

motor tube and tie a square knot

or bowline knot near the notch in

the forward centering ring. Apply

some epoxy to the knot to make

sure it doesn’t come loose later.

Make sure the Kevlar loop is seated

against the forward centering ring so that it will not interfere with the fin tangs later. You

can tack with epoxy or CA to hold in place.

Fin Tang

Apply CA or

Epoxy to knot

Push cord in corner

and tack with epoxy

Step 3 – Insert Motor Tube Assembly into Body Tube

Wrap the shock chord into a small bundle and stuff it inside the motor tube for this next

step. Make sure the cord passes over the notch in the forward centering ring. Test fit the

motor tube assembly into the body tube to ensure a snug fit. Sand the centering rings if

necessary. When you are satisfied with the fit, spread some epoxy on the inside of the

body tube and slide the forward centering ring of the motor assembly into the body tube.

Spread some more epoxy on the inside edge of the body tube before sliding the tail cone

into the body tube. Continue sliding the assembly inside the body tube until the tail cone