continue INSTALLATION

1) Install the pump as close to the pool as possible, to reduce

friction loss and improve ef ci

if ency, use short, direct suction

and return piping.

2) To avoid direct sunshine, heat or rain, it is recommended

to place the pump indoors or in the shade.

3) DO NOT install the pump in a damp or non-ventilated

location. Keep pump and motor at least 150mm away from

obstacles, pump motors require free circulation of air f

f

or cooling.

4) The pump should be installed horizontally and xed i

i

n the

hole on the support with screws to prevent unnecessary

noise and vibration.

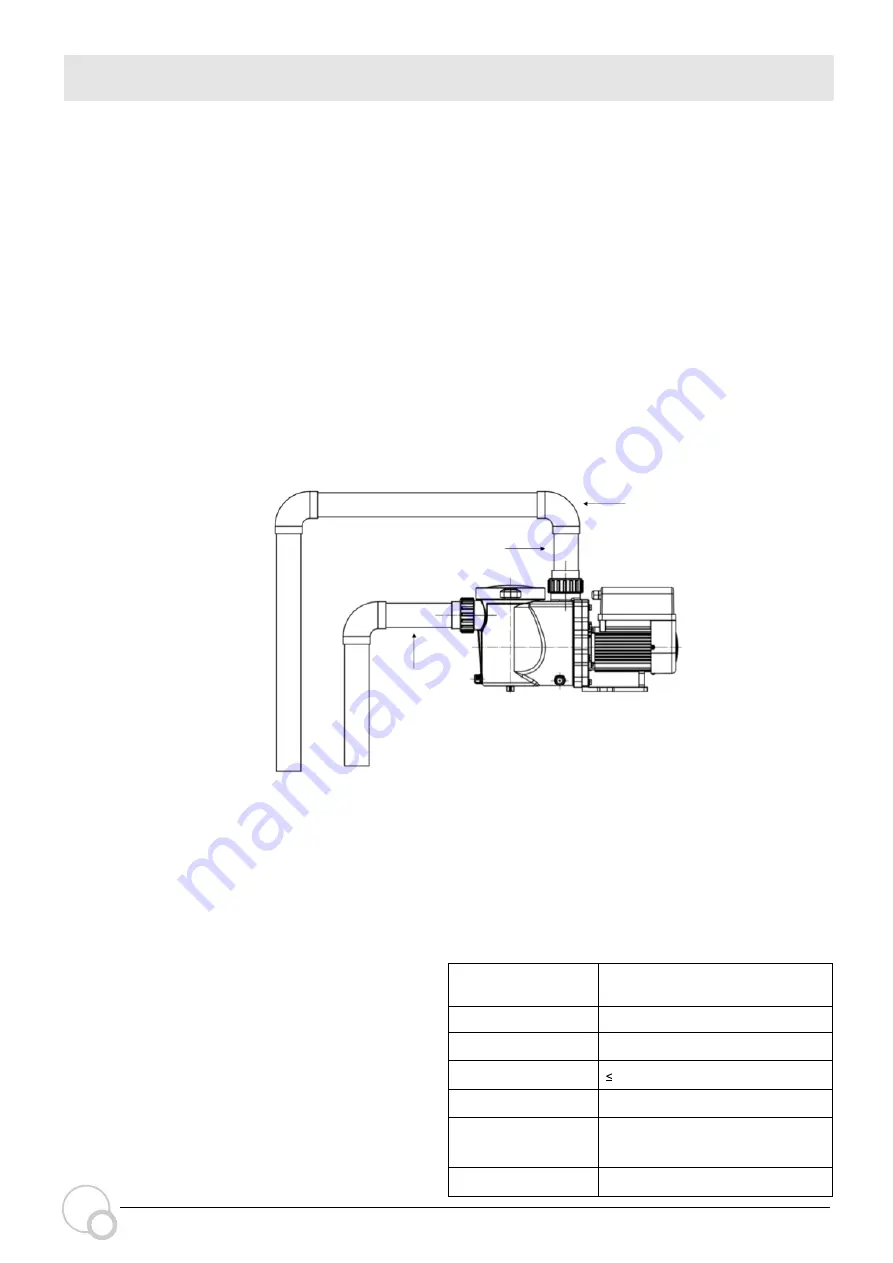

4.2 Pump Location

* The pump inlet/ outlet union size: optional with metric 50 or 40mm.

2) Below water level system should have an isolation valves installed on suction and return line f

f

or maintenance; however, the suction

gate valve should be no closer than seven times the suction pipe diameter as described in this section.

3) A check valve shopuld be installed if there are long pipe runs aboave water level or if is signi icant height between the return line

and

the outlet of the pump.

4) Be sure to install check valves when plumbing in parallel with other pumps. This helps prevent reverse rotation of the impeller and

motor.

4.4 Valves and Fittings

1) Check whether pump shaft rotates freely;

2) Check whether power supply voltage and frequency conform

to the nameplate;

3) Facing the fan blade, the direction of motor rotation should

be clockwise;

4) It is forbidden to run the pump without water.

4.5 Check before initial startup

4.6 Application conditions

1) For optimization of the pool plumbing, it is recommended to

use a pipe with size of 50mm. When installing the inlet and outlet

tti

i ngs

f

(joints), use the special sealant for PVC material.

2) The dimension of suction line should be the same or larger

than the inlet line diameter, to avoid pump sucking air, which will

affect the eff ci

i ency of the pump.

3) Plumbing on the suction side of the pump should be as short

as possible.

4) For most installations we recommend installing a valve on

both the pump suction and return lines, which is more convenient

for routine maintenance. However, we also recommend that a

valve, elbow, or tee installed on the suction line should be no close

e

r

to the front of the pump than seven times the suction line diamete

r

5) Pump outlet piping system should be equipped with a check

valve to prevent the pump from the impact of medium recirculation

and pump-stopping water hammer.

4.3 Piping

Ambient temperature

Indoor installation, temperature range:

-10 ~ 40°C

Water temperature

Salt pools

Salt concentration up to 0.5%, i.e. 5g/L

Humidity

Altitude

Not exceed 1000m above sea level

Installation

The pump can be installed max. 2m

above water level

Insulation

Class F, IP55

5°C ~ 50°C

90% RH,

(

20°C±2°C

)

The pump should be installed in an area with at least 150mm

distance around the unit away from any obstacles and away

from any corrosive products.

Suction and return connections on the pool pumps are 50mm

pressure pipe dimensions.

It is recommended to install isolation valves on the suction and

return lines for easier maintenance of the pool pump.

Elbows should be no closer than 350mm to the inlet.

Do not install 90° elbows directly into the pump inlet/outlet.

Joints must be tight.

Elbow

Return to pool 50mm

350mm

Suction

50mm

4

INVER

FLOW

Summary of Contents for invermac inverFLOW INVFLO300

Page 1: ...Powered by INSTALLATION MANUAL...

Page 12: ...AG045 DE 05...