continue SETTING AND OPERATION

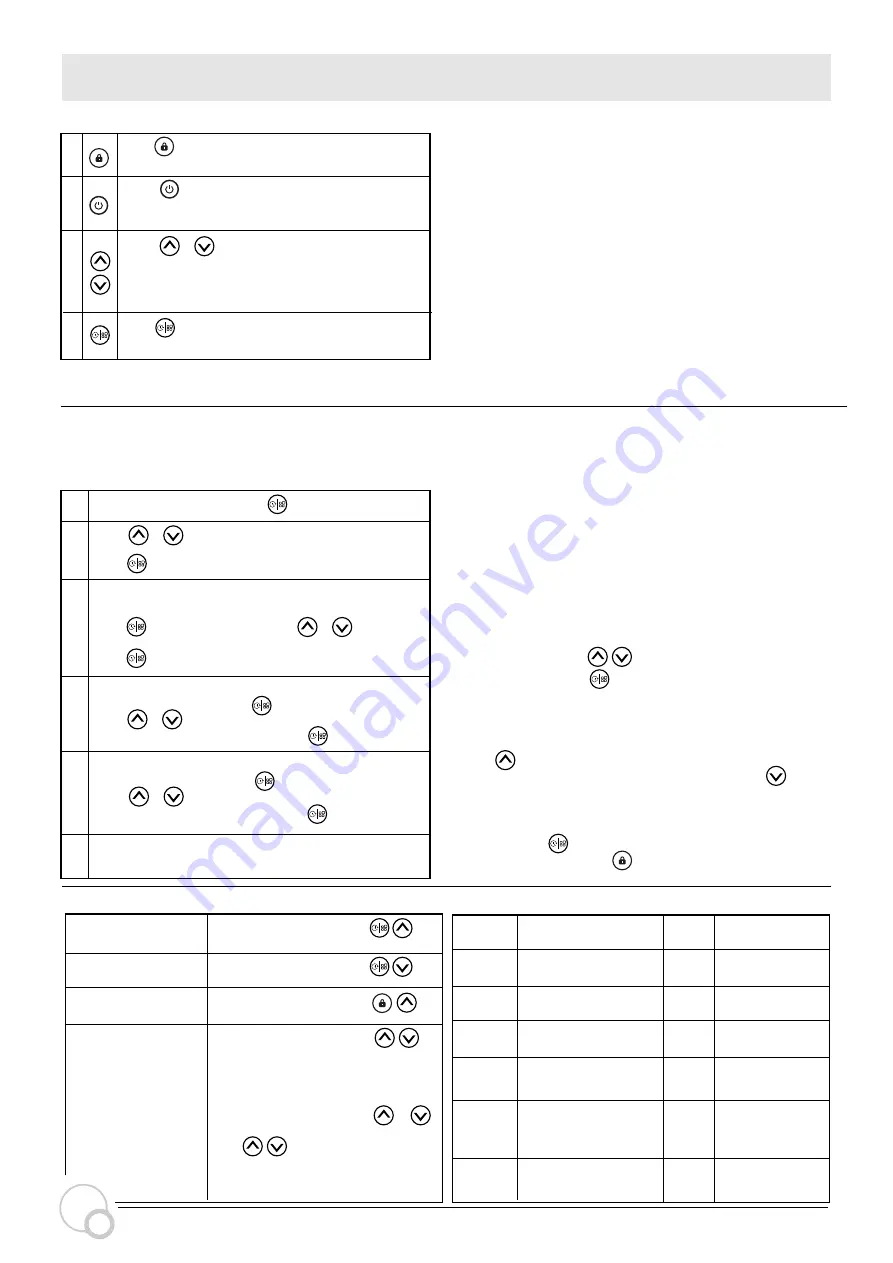

5.4 Running Capacity Setting

5.5 Timer mode

The pump’s on/off and running capacity could be commanded

by timer, which could be programmed daily as needed.

Maximum 4 timers can be set on the control panel.

Enter timer setting by pressing .

Press or to set the local time.

When enter the timer-1 setting, the timer indicator 1

will light up. “StA”will be shown on the screen.

Press to proceed and then press or to set the

start time of timer-1 (with 30 minutes for each step),

press to con

fi

rm.

Press to confirm and move to timer-1

When the start time of timer 1 is con

fi

rmed, “End”will be

shown on the screen. Press to proceed and then

press or to set the end time of timer-1

(with 30 minutes for each step), press to con

fi

rm.

When the end time of timer 1 is con

fi

rmed, “SPd”will be

shown on the screen. Press to proceed and then

press or to set the running capacity of timer-1

(30% - 100%, each step by 5%), press to con

fi

rm.

When the timer 1 setting is completed, repeat steps 3 – 5

to complete the setting of timer 2 – 4.

Hold for more than 3 seconds to read the

real-time power.

Press or to set the running

capacity between

30%~100%, each step by 5%.

Press to start. The pump will run at 80% of the

running capacity at the initial startup after the

self-priming.

NOTE:

When timer mode is acti

v

ated, if the set time period contains the

current time, the pump will start running according to the set running

capacity and the corresponding timer indicator (1 or 2 or 3 or 4) will

stay on, and the set running capacity will be shown on the screen.

If the set time period does not contain the current time, the timer

indicator (1 or 2 or 3 or 4) that isabout to start running will light up

and flash, and the current time will be shown on the screen.

All 4 time periods should be set in chronological order.

O

v

erlap setting of time will be considered in

v

alid, the pump will only

run based on the pre

v

ious

v

alid setting.

During the timer setting, if users want to return to the pre

v

ious

setting item, hold both for 3 seconds. If users don’t need

4 timers, they can hold for 3 seconds after completing the

setting of the speci

fi

c timer, the system will automatically sa

v

e the

current set

v

alue and acti

v

ate the timer mode.

When the timer mode is on, users can check the setting of each timer.

Press to select the speci

fi

c timer (1 or 2 or 3 or 4), and the

corresponding timer indicator will light up. Then press to check

the start time, end time, and running capacity setting of the

selected timer.

Users can hold for 3 seconds to read the real-time power and

exit timer mode by holding for 3 seconds.

2

3

4

1

2

3

4

5

6

Hold for more than 3 seconds to unlock the

screen.

1

Note:

a. When the running capacity is adjusted, the system will sa

v

e the

latest parameter automatically.

b.When setting 100% speed, the pump will increase the speed

automatically if the pipeline resistance is high, but will not exceed

the rated power of each model.

5.6 Parameter Setting

Description

Default

Setting Setting Range

1

100%

2

80%

3

40%

4

100%

5

25

Restore factory setting.

Under off mode, hold both for

3 seconds.

Check the software

v

ersion.

Under off mode, hold both for

3 seconds.

Manual priming.

Enable or disable the

priming that occurs at

start.

Backwash

capacity

25:enables

0:disables

80~100%, by 5%

increments

30~100%, by 5%

increments

30~100%, by 5%

increments

30~100%, by 5%

increments

Under ON mode, hold both for

3 seconds.

Enter parameter

setting as shown.

Under OFF mode, hold both

for 3 seconds to enter the parameter

setting. The parameter address

(on the left) and default setting

v

alue

(on the right) will flash alternately on

the screen. Users can press or

to adjust the current

v

alue, and hold

both for 3 seconds to the next

parameter address. It will exit the

parameter setting after 10 seconds

without operation.

Parameter

Address

6

INVER

FLOW

Self-priming/

2min

6

Self-primming

recheck time

1-15min by 1min

increments

Digital input 2

Digital input 3

Digital input 4

For the purpose of

backwashing, users can set a high running capacity

according to the size of filter.

Summary of Contents for invermac inverFLOW INVFLO300

Page 1: ...Powered by INSTALLATION MANUAL...

Page 12: ...AG045 DE 05...