CONTROL ELEMENTS

Exterior lighting

Operating manual MT 32 / 36

53

Hazard lights

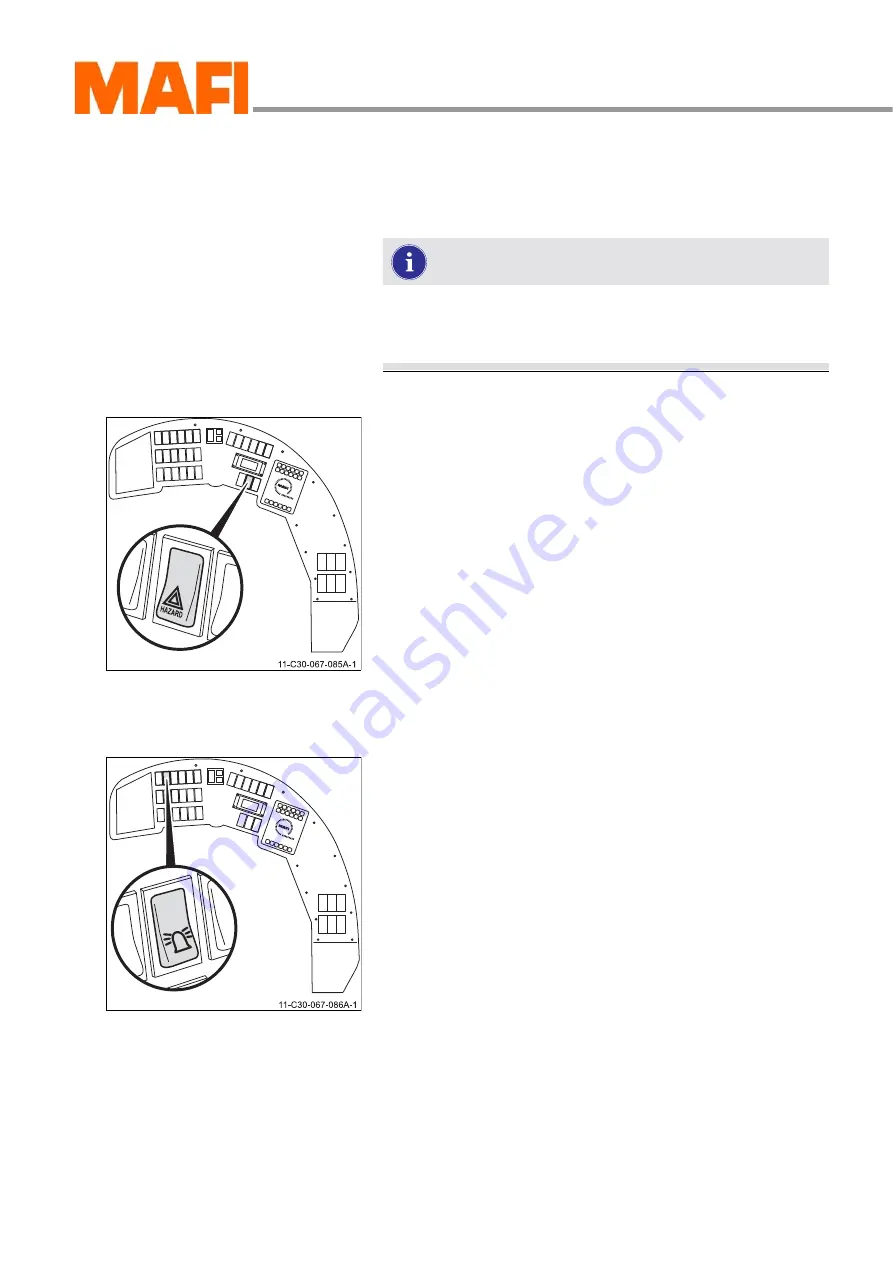

The switch for the hazard lights is installed in the instrument

panel.

S w i t c h t h e h a z a r d l i g h t s o n w h e n eve r yo u h ave t o s t o p

i n a n e m e r g e n c y. Yo u c a n t h e r e by wa r n o t h e r s a b o u t

p o s s i bl e d a n g e r s.

Fig. 34: “Hazard lights” switch

Switching on the hazard lights

X

Press the switch.

3

The hazard lights are on and the driving direction indica-

tors on the multi-function display flash simultaneously.

Warning beacon

The switch is installed in the instrument panel.

Fig. 35: “Warning beacon” switch

Switching on the warning beacon

X

Press the switch.

3

The warning beacon is switched on.

Summary of Contents for Trac G Series

Page 1: ...Operating manual MAFI Trac MT 32 36 Series G get it rolling Production no 3321128...

Page 8: ...6 Maintenance manual MT 32 36...

Page 32: ...30 Operating manual MT 32 36...

Page 124: ...OPERATION Care 122 Operating manual MT 32 36...

Page 125: ...Operating manual MT 32 36 123 TRANSPORT Loading onto a flatbed trailer Loading with a crane...

Page 140: ...SELF HELP Inflating tyres 138 Operating manual MT 32 36...

Page 148: ...TECHNICAL DATA Brake system 146 Operating manual MT 32 36...

Page 152: ...150 Operating manual MT 32 36...