©

Install_CelmerSL100P - All specification and suggested dimension is for reference only- subject to change without further notice.

6

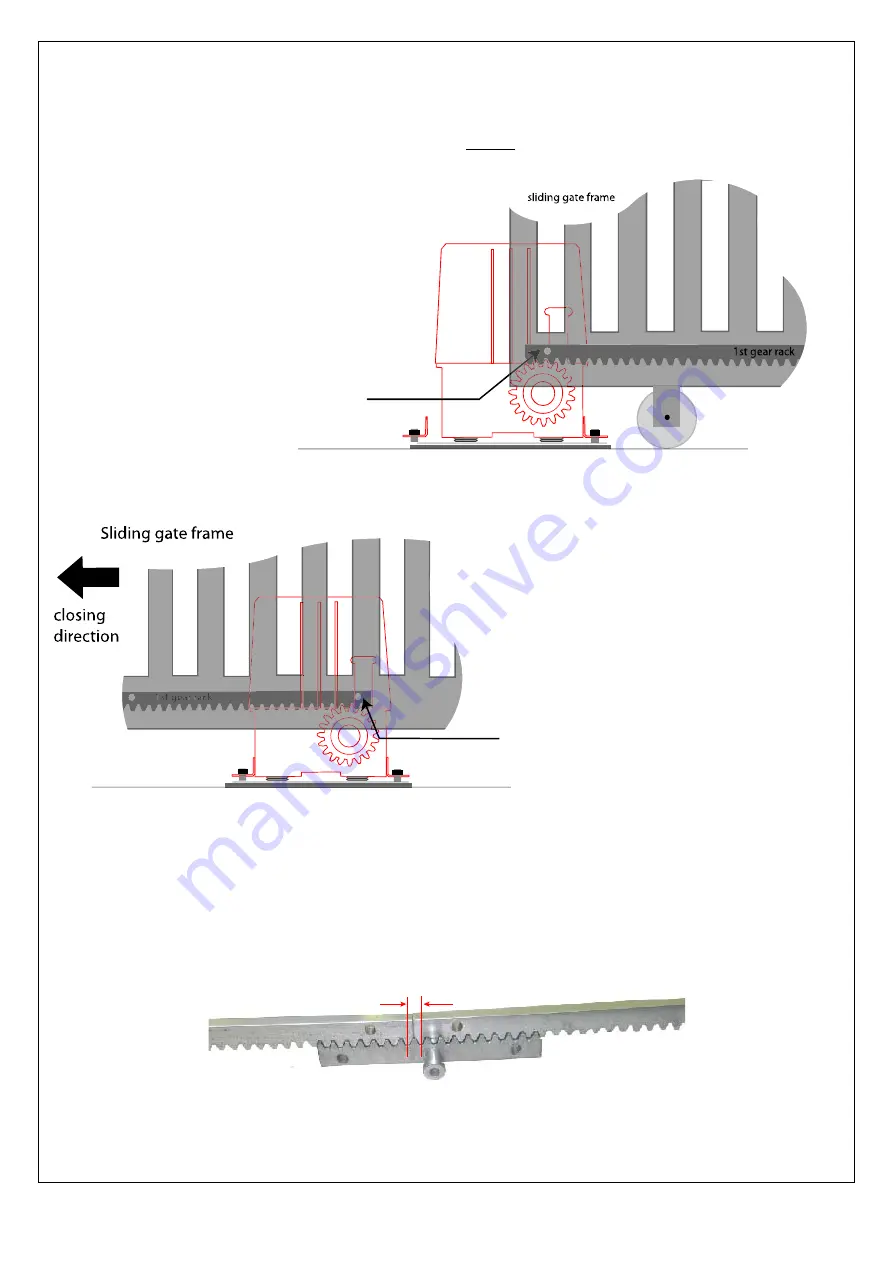

Installing the gear rack

Gear rack mounting location must be parallel to the pinion gear horizontal axis after the operator motor is fully

mounted at that specific installation site. Using alignment liquid level ruler or simply following the gate frame is not an

accurate method. The gear rack location must be determined relative to the pinion gear location. The following is the

method suggested. Release the motor clutch for free rotation during installation.

Now the gear rack horizontal axis should be aligned to be parallel to the pinion gear axis. With minima effort try to

slide the gate back and forth within the gear rack length and make sure the movement is smooth and even.

Repeat the same installation procedure for all subsequent gear racks that are needed to reach the position of

complete closing. Use a section of rack of about 150 mm to ensure that the teeth-to-teeth distance of subsequent

gear rack is spaced correctly - see illustration below.

After installing all the required gear racks, manually check if the gate can open completely and the movements of the

gate is smooth and even. Full weld all the spacer to the gate frame. Tighten the motor clutch back. IMPORTANT: Do

not weld the rack section to the spacers or to each other. Do not apply grease or other lubricant to the pinion and rack.

Slide the gate open by hand. Place the first section

of the rack on the pinion, aligning it with the first

spacer. The pinion gear teeth should fit into the

gear rack teeth with almost no spacing.

Secure the gear rack to gate using a clamp.

Spot weld the first spacer to the gate frame.

Slide the gate towards its closed position until

the third spacer of gear rack is on top of the

pinion gear.

Secure the position of the bolt and spacer to

gate through gear rack's last screw hole.

Spot weld the second and third spacer to the

gate frame

Correct teeth-to-teeth distance at the joint