©

Install_CelmerSL100P - All specification and suggested dimension is for reference only- subject to change without further notice.

9

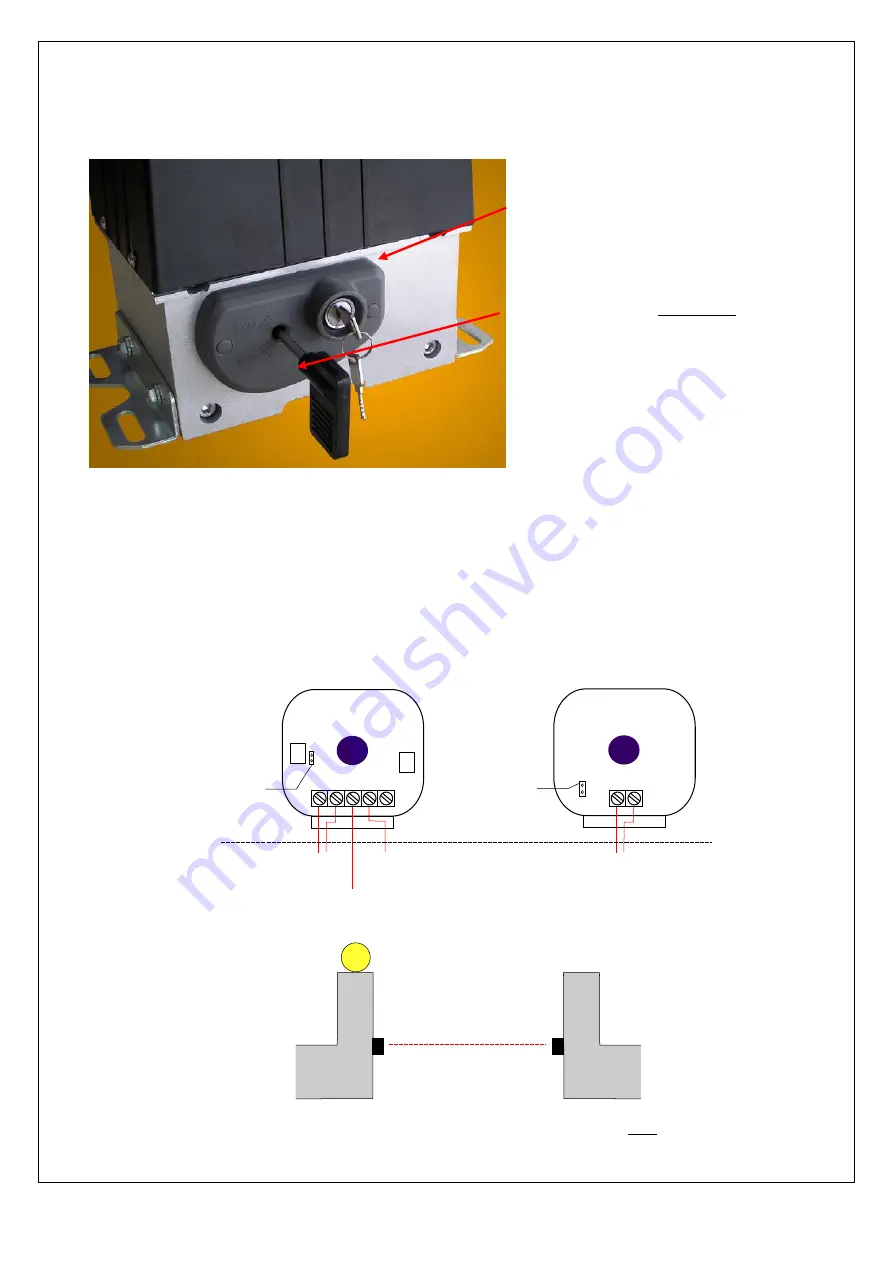

Manual Operation

Should the need arise to operate the gate manually because of power failure or malfunction, release the clutch so that

the motor are free to rotate. This can be done with the following procedure:

CAUTION:

DO NOT turn the Alan key all the way to the end – this will cause the clutch to be completely

disengage from the gear system and unable to be tighten back later. Turn the Alan key only 2 round or less

will be able to free the clutch for manual sliding. The clutch needs to be tighten back for the automatic gate

system to resume operation.

Optional installation of photo beam

The approved photo beam to be used together with SL100P system is ART104 from DEA (Italy). Photo beam is to be

installed on the wall pillar facing each other aligning to an horizontal axis. The corresponding jumper wire on F1 board

needs to be cut to enable photo beam function. The following is the detailed wiring of the photo beam:

NO

-

C NC

+

AC24V - shared power

supply with remote

control receiver.

Common CM

share with limit switch

PIB input

F1 control panel

Power selection

No jumper - AC24V

With jumper - DC12V

-

+

AC24V - shared power

supply with remote

control receiver.

Power selection

No jumper - AC24V

With jumper - DC12V

Transmitter (TX)

Receiver (RX)

IR beam passing horizontal across

the gate entrance. Trigger signal

will be sent to control board once

IR beam is blocked by obstacle.

pillar wall

© COPYRIGHT 20 Feb 2012. All diagrams are for illustration only and does not necessary reflect the actual exact assembly/installation. This

documentation served as a reference only. It is subject to change without further notice. All the diagrams and information in this documentation

may not be duplicated or modified in any form without the written approval from

MAG®

.

1)

Use the key supplied to unlock the

clutch

2)

Turn the Alan key TWO round anti-

clockwise to release the clutch