6

Removal of excess heat

D - boilers are equipped with a cooling safety exchanger against overheating of the boiler (Fig. 1), which provides

safe dissipation of excess heat not to exceed 110 °C. If boiler is overheated (water outlet temperature is higher

than 95 °C) safety valve (e.g: Danfoss BVTS, Honeywell TS 130 or WATTS STS 20) opens ap the cooling circuit

and the cold water begins to flow through the cooling heat exchanger boiler. After the temperature decreases, the

valve closes. Input water pressure just before the premium cooling circuit must be between 2-6 bar. Before

entering into the cooling water valve is recommended to place a water filter that needs to be checked and cleaned

regularly.

NOTE:

Excess hot water need to be removed directly to canalization. It must not be used for different purposes.

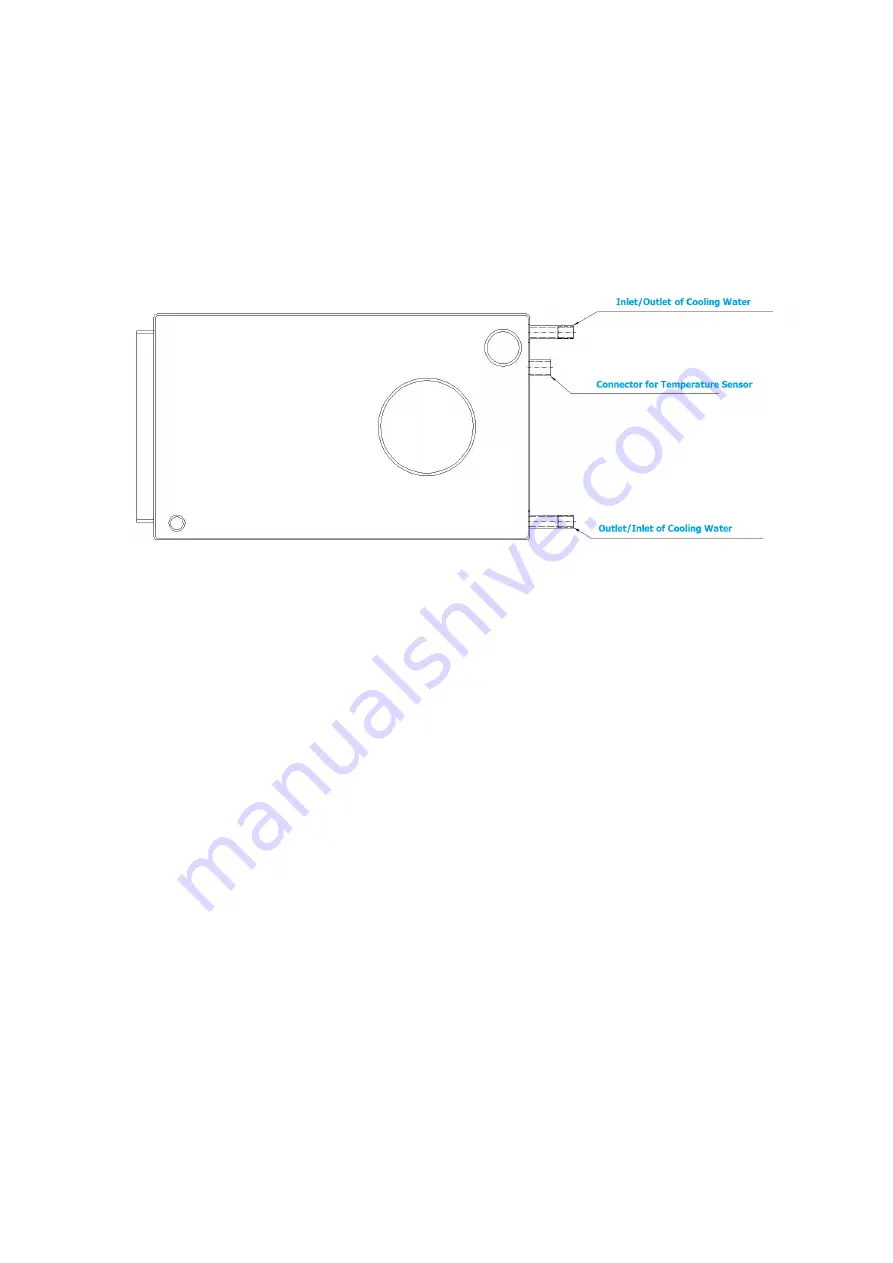

Fig. 1 Connection of cooling exchanger

5.

Heating System and Boiler Maintenance

You should check the water level in the heating system at least once in every 14 days. If necessary,

refill water. Refilling must at all times be carried out with the boiler out of operation. If, during winter

season, your boiler is out of operation, there is a danger that the water remaining in the system may freeze

causing damage to the system. In such an event use antifreeze designed for operation of heating systems.

Water should be pumped out of the system in exceptional cases only. If possible, drain the water from the

system for a minimum necessary amount of time. Thorough cleaning of the boiler after the end of a heating

season is essential.

6.

Fuel

The prescribed type of fuel is dry, two years old wood with 20 percent or less moisture content.

Logs: length 350 mm to 500 mm, calorific value of 14 – 17 MJ.kg

-1

and diameter ø 60-120 mm.