26. SPARE PARTS REQUEST

ATTENTION!

FILL IN DETAILS THIS FORM

Customer

…………………………………………………………..

Address

…………………………………………………………..

…………………………………………………………..

Date …………………………………………………….

Telephone number

…………………………………………………………..

Telefax

…………………………………………………………..

NOTE

………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………

N.B.:

Please attach a copy of each table where the requested part is.

MACHINE TYPE

SERIAL NUMBER

DELIVERY DATE

GROUP CODE

CODE

PART NAME

QUANTITY

Summary of Contents for BORING SYSTEM 35

Page 2: ...Page intentionally left blank...

Page 4: ...Page intentionally left blank...

Page 7: ...NOTES...

Page 38: ...Page intentionally left blank...

Page 40: ...26354000 FRAME UNIT SHEET 1...

Page 42: ...26354100 TABLE UNIT SHEET 2...

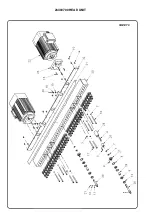

Page 44: ...26300200 RACK UNIT SHEET 3...

Page 46: ...26054300 26054301 LH RH SQUARE UNIT SHEET 4...

Page 48: ...26354401 SPINDLE HEAD UNIT SHEET 5...

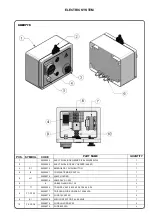

Page 50: ...26300500 CLAMPING UNIT SHEET 6...

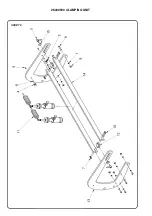

Page 52: ...26054502 CLAMP UNIT CLAMPING UNIT SUBGROUP SHEET 7...

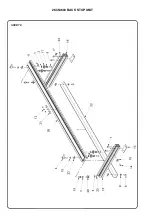

Page 54: ...26354600 BACK STOP UNIT SHEET 8...

Page 56: ...26300700 HEAD UNIT SHEET 9...

Page 58: ...SHEET 10 26054810 1 5 1 5 Mt EXTENSION FENCE N 4 ROTARY STOPS UNIT...

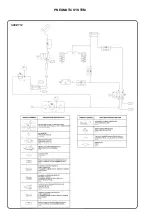

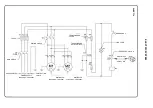

Page 60: ...PNEUMATIC SYSTEM SHEET 12...

Page 65: ...Page intentionally left blank...