Page 30

CAUTION

CAUTION

DANGER

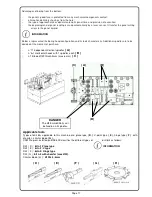

Only use fork-lift trucks having the suited carrying capacity and suited fork length.

It is very important to avoid any collision during the whole loading and carrying

procedure and to keep the machine always in balance.

Make sure that the forks of the lift truck are well positioned under the machine, so that its centre of gravity is

well balanced, thus ensuring the greatest stability of the whole loading.

An unbalanced load create dangerous conditions which persist during the whole carrying procedure

4.3.4 Conditions for the machine’s safeguard

All parts subject to rust and corrosion are adequately protected against oxidation and atmospheric agents by

protective greasing and spraying. Having to keep the machine stored for a short time make sure that the de-

signed location is free from humidity and that the packaging is undamaged and well dry. Under particular stor-

age conditions, for example storage inside a container, You have to make sure that the container is adequately

protected against atmospheric agents such as rain, snow and hail and that access is allowed to authorized

personnel only.

Having to keep the machine stored for a longer time it is necessary to undertake further protective measures

such as the greasing of all bearings and tooled parts

4.3.5 Control for possible damages

On receipt of the machine You are requested to check it in order to detect possible damages. Before unpacking

the machine make sure that there are no spares or accessories fixed to the cartons and boxes just to avoid

damaging them.

4.4 Preparation of the installation area

The machine is designed to stand on its small feet. The installation area has to be equipped with pneumatic

and electrical connection points.

Before installing the machine make sure that the floor carrying capacity is suited to the purpose. Do

verify that there are no electrical cables nor water pipes lying across the assigned area.

4.4.1 Installation requirements

The machine installation has to be carried out on a flat surface having the suited carrying capacity. It is essen-

tial that the installation floor is well leveled - maximum allowed and non cumulative error is + 0,25 mm / m

( even by using risers), ruling gradient allowed up to + 0,3 % in all directions.

CAUTION