035-000049-001

Page 19

HCA IOM 1.1 8-28-2017

START-UP

Pre-Startup

BUILDING ENVELOPE

—

All building windows and

doors should be installed and closed before starting

unit. During summer construction, avoid unit sweating

by allowing for gradual pull down: use elevated chilled

water temperature, reduce chilled water flow rate

(gpm), use maximum available airflow.

HEATING FLUID TEMPERATURE-Maximum entering

water temperature is 180°F, unless nameplate indicates

200°F.

CAUTION

: If unit is marked for 200°F maxi-

mum entering water temperature, customer must en-

sure that water vaporization does not occur especially

at higher elevations when entering water temperatures

are greater than 190°F.

TEMPERATURE CONTROLS-Check that unit or wall

mounted thermostat or field-supplied controller is con-

nected to the unit.

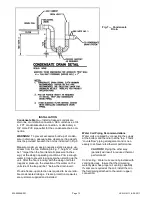

OUTSIDE AIR AND FREEZE PROTECTION-

WARNING: Insure that the unit is protected against

freezing conditions Failure to provide freeze pro-

tection may result in equipment or property dam-

age.

Freeze protection measures are customer-

provided and installed and include but are not limited to

low-limit thermostats, automatic temperature controls,

and use of glycol based heat transfer fluids (see section

FREEZE PROTECTION OF WATER PIPING).

1. If “locking quadrant” manual damper operator pro-

vided, set to desired position.

2. If damper actuator provided, insure that actuator

opens the damper when the fan turns on, and closes

when fan stops. Test mixing box controls to make sure

OA damper closes on power failure or upon activation

of customer-supplied and installed low limit thermostat

or other freeze protection device.

Start-Up Check List —

Remove all construction debris

from unit interior.

Remove tools and all foreign objects

before starting unit. Checklist—perform full startup

checklist located on the last page of this manual, and

submit to the factory to register the warranty.

FILTERS — Install unit filters in all filter sections. Pro-

tect open filters from drywall dust and construction de-

bris.

MOTOR/FAN ASSEMBLY

1. Hand turn fan to make certain it turns freely and fan

wheel does not rub the inlet ring.

2. Check fan speed with a laser-type tachometer to

confirm operating speed (access doors must be

closed to apply correct external static pressure to

the fan).

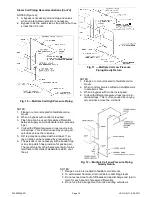

3. Check direction of rotation (see Fig. 15).

4. Check vibration. If excessive vibration occurs,

check for the following:

A. Shipping screws removed.

B. Inadequate airflow.

C. Damaged wheel.

D. Loose mounting bolts.

E. Wheel or motor out of balance.

F. External vibration isolators improperly ad-

justed.

G. Out-of-balance or corroded wheel

(rebalance or replace if necessary).

H. Accumulation of material on wheel (remove

excess material).

Fig. 15 — Fan Wheel Rotation

COILS

1. Make sure freeze protection measures are

in place to protect water coils from freezing

(see section FREEZE PROTECTION OF

WATER PIPING).

2. Make sure hydronic (water based chllled

water and hot water) systems are filled and

have air removal devices in operation.

3. For hydronic coils with 3ea connections,

make sure that the supply connection is at

the bottom (air leaving side of coil) and re-

turn connection is in the middle (air entering

side of coil), and the top connection is

capped with the factory-provided cap.

Start-Up—Run Fan, Set Airflows

CONTROLS

Set up control system so that it correctly runs

the fan as needed and activates control valves

when required. Note that operating cooling with

the fan off can cause the cabinet temperature to

become too low and result in condensation in-

side and outside the unit cabinet, leading to un-

safe conditions. When fan is not running, cool-

ing should be inactive.

START THE FAN

With 4-Speed Control:

1. Using a thermostat: Route R, C and G1

connections in the HCA control box to the

matching thermostat connections (include

G2 and G3 if required). Set thermostat to

run the fan at speed G1.

2. Without a thermostat: Jump together the R

and G1 terminals in the control box.

3. While fan is running, adjust potentiometer

marked “FLO1” that controls fan speed G1

using a small flat blade screwdriver. Repeat

for the other speeds as needed.

With 0-10VDC Control:

1. Using a thermostat: Route R, C, + (plus)

and -(minus) connections in the HCA control

box to the matching thermostat connections.

Set the thermostat to run the fan.

2. Without a thermostat: Provide a DC control

voltage across the + (plus) and — (minus)

terminals.

3. Fan starts at 2.0VDC. Fan speed varies

across available range (pre-programmed at

factory) from 2.0 VDC (minimum speed) to

10.0 VDC (maximum speed).

Summary of Contents for HCA Series

Page 2: ...035 000049 001 Page 2 HCA IOM 1 1 8 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 26: ...035 000049 001 Page 26 HCA IOM 1 1 8 28 2017...

Page 28: ...035 000049 001 Page 28 HCA IOM 1 1 8 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 29: ...035 000049 001 Page 29 HCA IOM 1 1 8 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...