Page 13 of 20

507389-02

Issue 1733

5. Set the room thermostat to the desired temperature.

If the thermostat “set” temperature is above room

temperature after the pre-purge time expires, main

burners will light.

To Shut Down Main Burners

1. Turn off electrical power to unit.

2. Move the ON/OFF switch to the “OFF” position (see

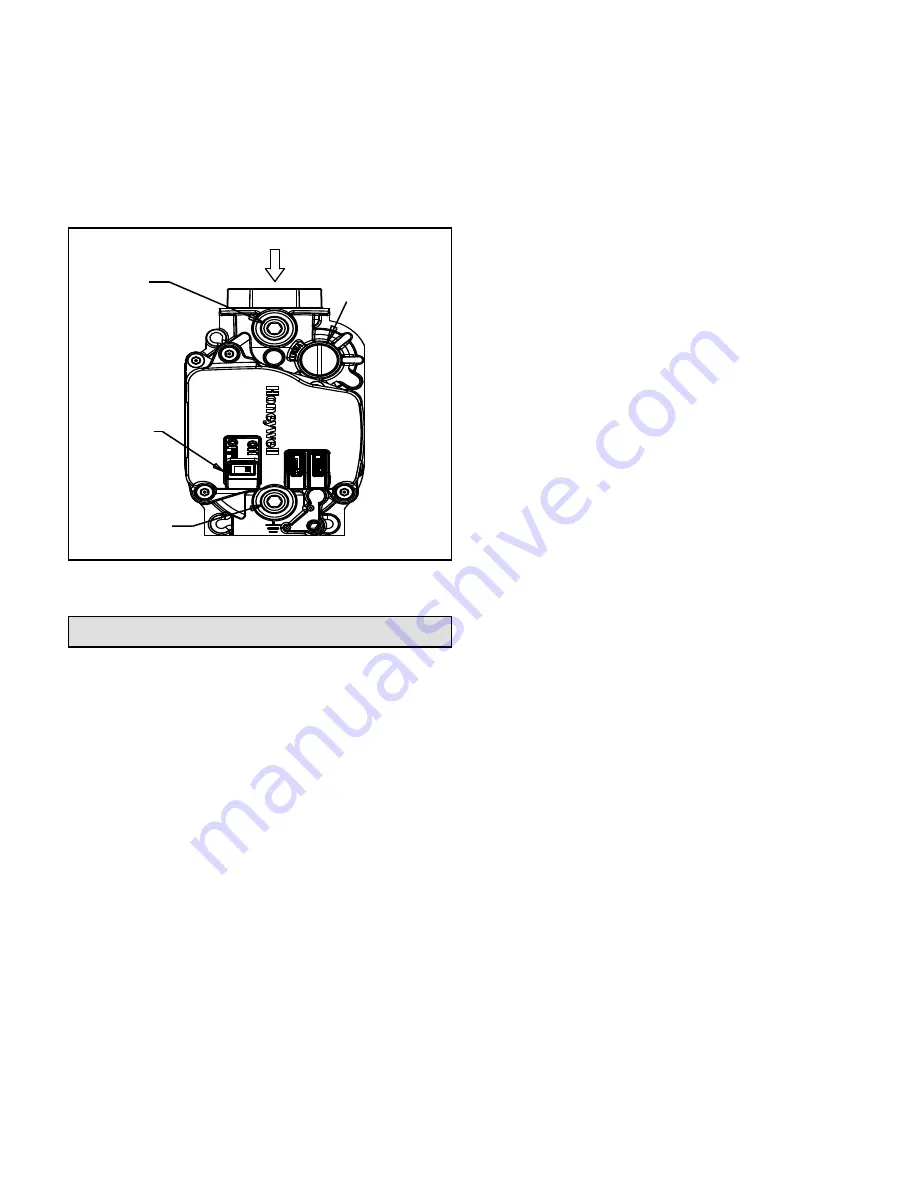

Figure 9. Gas Valve

Gas Inlet

ON/OFF

Switch

Gas Inlet

Pressure

Test Tap

Regulator

Adjustment Screw

(under cap)

Gas Manifold

Pressure Test

Tap

Operation

Operation of the unit is automatic and will provide heating

and cooling depending on the setting of the thermostat.

Heating

1. Turn on main power supply.

2. Open manual gas shutoff valve.

3. Set thermostat system to “HEAT”.

4. Set thermostat to temperature desired.

Cooling

1. Turn on main power supply.

2. Set thermostat system switch to “COOL”.

3. Set thermostat to temperature desired.

Heating Sequence of Operation

1. Thermostat calls for heat.

2.

Combustion blower starts and proper air flow is proven

by the pressure switch closing.

3. Blower continues to operate for 30 seconds prior to

the burners lighting.

4.

Ignition control begins spark and opens gas valve. The

burners are lit. Ignition is proved through the flame

sensor.

5. Circulating air blower starts 30 seconds after the

burners light.

6.

When the thermostat is satisfied, the burners and

combustion blower shut off.

7. Circulating air blower will shut off 120 seconds later.

If the burners should fail to ignite, the ignition control will

try to ignite the burners a total of three times. Should the

burners fail to ignite within the three trials for ignition, the

ignition control will lock out for 1 hour before beginning

another ignition cycle. To reset the control, turn the

thermostat down or off for 10 seconds and then set to

desired setting. At this time, the ignition sequence will try

again.

Blower Control

The blower will start approximately 30 seconds after the

burners ignite and will stop approximately 120 seconds

after the thermostat is satisfied. The time delay is preset at

the factory and timing can not be adjusted.

Cooling Sequence of Operation

When the thermostat system switch is set for “COOL”, the

blower will start 5 seconds after the thermostat calls for

cooling and will stop 90 seconds after the thermostat is

satisfied.

Continuous Fan Operation

Continuous operation of the air handling blower will be

obtained if the thermostat fan switch is set to “ON”. With

the thermostat fan switch set to “AUTO”, the air handling

blower will cycle corresponding with the thermostat cycling.

To Shut Down Unit

For temporary or short periods of shutdown, set the

thermostat system switch to “OFF”. For a prolonged period

of shutdown, set the thermostat system switch to “OFF”

and turn off the electrical power supply and the gas supply

to the unit.