Page 17 of 20

507389-02

Issue 1733

2. Disconnect the orange and yellow wires at the rollout

switch.

3. Remove the screw and slip the rollout switch from

beneath the lanced tab on the burner assembly.

4. For reassembly, follow the above steps in reverse

order.

Flame Sensor

1.

Remove the control board mounting bracket as

described previously.

2.

Remove the screw and pull the flame sensor from the

bottom of burner assembly.

3. For reassembly, follow the above steps in reverse

order.

Primary Limit Switch

The primary limit will shut down the unit in case of

overheating and automatically resets when temperature

falls to an acceptable level. It is not field adjustable

1.

Remove the control board mounting bracket as

described previously.

2. Disconnect the orange and yellow wires at the primary

limit switch.

3. Remove the three screws securing the primary limit

switch to the vest panel.

4. For reassembly, follow the above steps in reverse

order.

Inducer Prover Switch

1.

Remove the control board mounting bracket as

described previously.

2. Disconnect the two purple leads at the inducer prover

switch.

3. If the tubing is in place, remove it.

4.

Remove the screw securing the switch to the bracket

and slip the strap end out of the hole in the bracket.

5. For reassembly, follow the above steps in reverse

order.

Burner Orifices

Orifices are threaded into the gas manifold. To remove

them:

1. Remove the burner & manifold assembly as described

previously.

2. Remove the four screws securing the gas manifold to

the burner assembly.

3.

Remove the orifices by unscrewing them. Do not use

any pipe thread sealant during reassembly.

4. For reassembly, follow the above steps in reverse

order.

Combustion Inducer

The combustion inducer can be removed for inspection,

replacement, or to access the heat exchanger and flue

tube extension for cleaning. To remove the combustion

inducer:

1.

Remove the control board mounting bracket as

described previously.

2. Disconnect the inducer motor leads.

3. Disconnect the inducer prover switch tubing at the

switch.

4. Disconnect the drain hose tubing at the collector box.

5.

Loosen the hose clamp at the inducer elbow-flue tube

joint (the upper hose clamp).

6. Remove the three screws securing the inducer to the

cold- end header box. Loosen clip at upper mount.

7. Pull the combustion inducer and elbow away from the

vest panel to move it free of the mounting legs on the

cold-end header box, while pulling the inducer elbow

free of the flue tube extension.

8. Pull the inducer and elbow out of the compartment.

9.

The flue tube extension can be cleaned if necessary.

Leave it in place; do not remove it from the unit.

10. If replacing the inducer with a new part, transfer

inducer orifice from old inducer. Attach inducer orifice

11. For reassembly, follow the above steps in reverse

order.

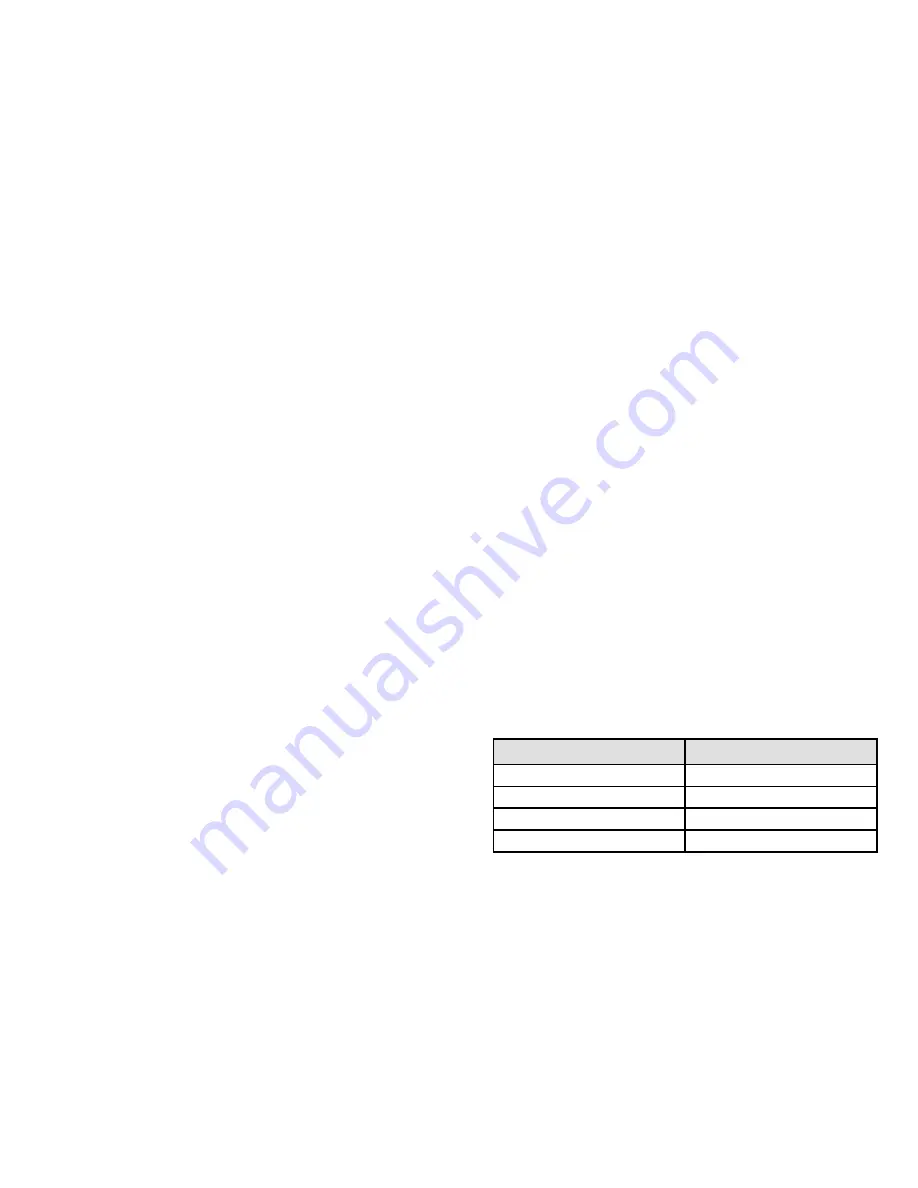

Combustion Inducer Orifice

The combustion inducer orifice meters the air flow needed

for proper combustion. Orifices are unique to each heating

input, and the correct one must always be used. The

orifices are color-coded as an aid. Refer to Table 3:

Model

Orifice Color

HWC9N22

Blue

HWC9N33

Black

HWC9N44

Gray

HWC9N55

Brown

Table 3.

Refer to Figure 12 to remove the combustion inducer

orifice: