Page 12 of 18

508196-01

Issue 2120

Maintenance

Disconnect all electrical power to the unit before

conducting any maintenance procedures. Failure to

disconnect the power could result in personal injury or

death.

WARNING

The refrigeration system normally requires no maintenance

since it is a closed, self-contained system.

Periodic inspection and maintenance normally consists of

changing or cleaning filters and (under some conditions)

cleaning the coils.

Filter

Inspect the filter once a month. Replace disposable filter or

clean the washable filter as necessary (a minimum of three

times each heating or cooling season is recommended).

To clean the washable filter, shake filter to remove excess

dirt and/or use a vacuum cleaner. Wash filter in soap or

detergent water and replace after filter is dry.

Motors

The indoor and outdoor fan motors are permanently

lubricated and require no maintenance.

Outdoor Coil

Foreign material should not be allowed to accumulate on

the outdoor coil surface or other parts in the air circuit.

Cleaning should be as often as necessary to keep the coil

clean. To clean the coil, remove the lower access panel

and blow out debris by using compressed air or water.

Be

sure power to unit is shut off before using water to

clean the coil.

Care should be used when cleaning the coils so that

the coil fins are not damaged.

Primary and Secondary Condensate Drain

Foreign material should not be allowed to clog the drain

hole. Inspect and clear drain opening prior to each heating

and cooling season.

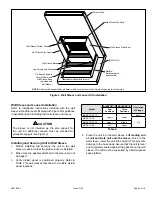

The defrost control is also equipped with a set of pins to

aid in the troubleshooting of the defrost system (see Figure

11). The following is a brief outline of the testing of the

defrost system.

1. Defrost sensor must be closed, 32°F or below. If

temperatures are such that the switch will not close,

jumper between defrost sensor terminals on the

defrost control.

2. Start system in heating operation.

3. Place the defrost pin jumper on the test pins for a brief

second, then place back on the proper defrost time

setting (30, 60, or 90). This will speed up defrost time

interval as shown in Table 7.

Defrost Control Setting

Defrost Test Cycle Time

30 minutes

7 seconds

60 minutes

14 seconds

90 minutes

21 seconds

Table 7. Defrost Test Cycle Time

The reversing valve will then shift to defrost mode and

the outdoor fan should stop. After 2 seconds of defrost

operation, the reversing valve should shift back to heating

operation and the outdoor fan should start.

Diagnostic LEDs

The state (Off, On, Flashing) of two LEDs on the defrost

board (DS1 [Red] and DS2 [Green]) indicate diagnostics

conditions that are described in Table 8.

Mode

Green LED (DS2)

Red LED (DS1)

No power to control

Off

Off

Normal operation /

power to control

Simultaneous slow flash

Timed lockout

Alternating slow flash

Low pressure switch

fault

Off

Slow flash

Low pressure switch

lockout

Off

On

High pressure switch

fault

Slow flash

Off

High pressure switch

lockout

On

Off

Table 8.