Page 8 of 18

508196-01

Issue 2120

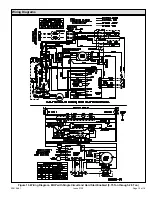

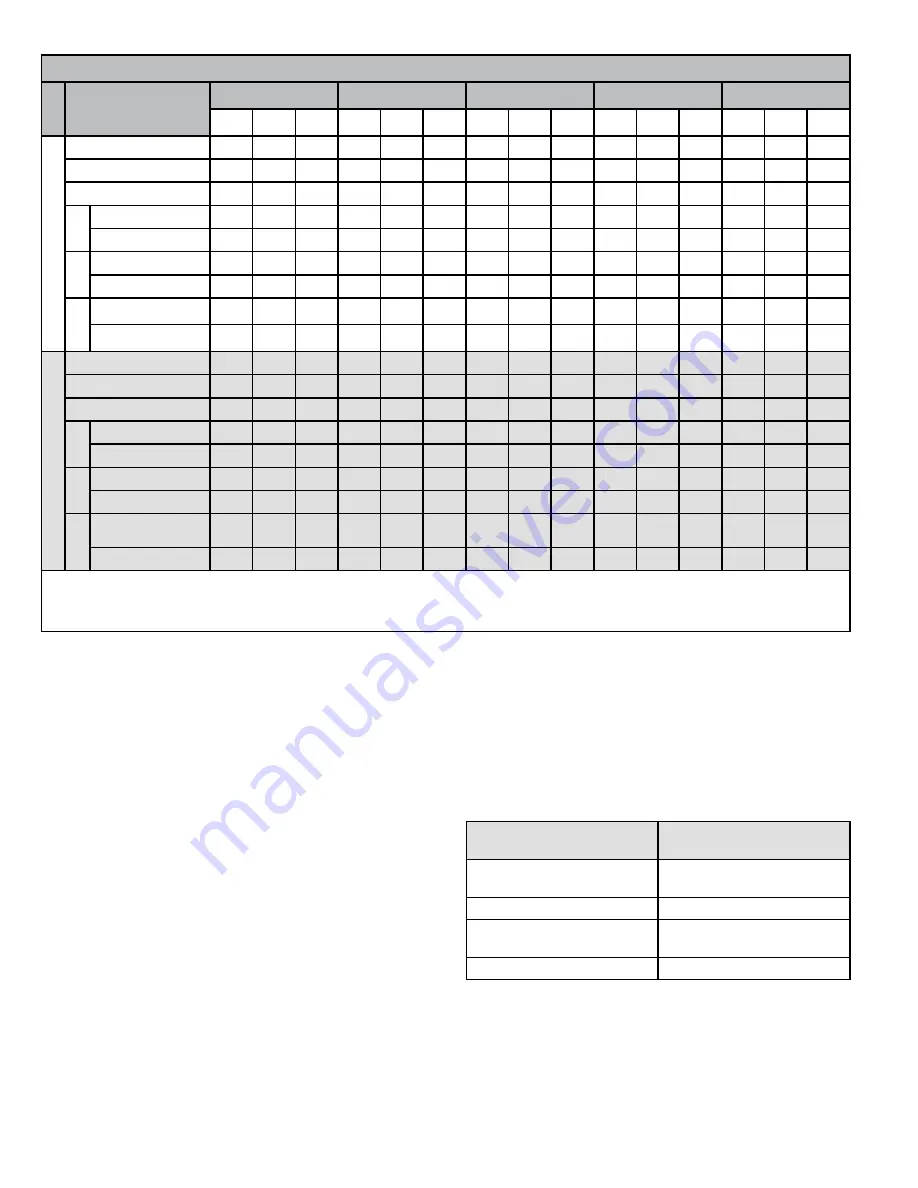

Airflow Performance as a Function of External Static Pressure

Model

Indoor Blower Speed

0.1 “w.c.

0.2 “w.c.

0.3 “w.c.

0.4 “w.c.

0.5 “w.c.

SCFM Watts

HP

SCFM Watts

HP

SCFM Watts

HP

SCFM Watts

HP

SCFM Watts

HP

*MHP4-12-301*P

TAP 1 (FAN)

590

43

0.06

535

48

0.06

430

55

0.07

380

60

0.08

315

65

0.09

TAP 2 (COOL/HP)

†

1040

161

0.22

1005

169

0.23

970

177

0.24

935

185

0.25

900

193

0.26

TAP 3 (COOL/HP)

N/A

N/A

N/A

1105

211

0.28

1070

220

0.30

1040

229

0.31

1010

237

0.32

5 kW

TAP 4 (AUX HEAT)*

1075

151

0.20

1040

159

0.21

1005

168

0.23

N/A

N/A

N/A

N/A

N/A

N/A

TAP 5 (AUX HEAT)

N/A

N/A

N/A

N/A

N/A

N/A

1100

205

0.27

1065

216

0.29

1025

225

0.30

7 kW

TAP 4 (AUX HEAT)*

1075

151

0.20

1040

159

0.21

1005

168

0.23

N/A

N/A

N/A

N/A

N/A

N/A

TAP 5 (AUX HEAT)

N/A

N/A

N/A

N/A

N/A

N/A

1100

205

0.27

1065

216

0.29

1025

225

0.30

10 kW

TAP 4 (AUX HEAT)*

1075

151

0.20

1040

159

0.21

1005

168

0.23

N/A

N/A

N/A

N/A

N/A

N/A

TAP 5 (AUX HEAT)

N/A

N/A

N/A

N/A

N/A

N/A

1100

205

0.27

1065

216

0.29

1025

225

0.30

*MHP4-14-361*P

TAP 1 (FAN)

680

61

0.08

630

68

0.09

575

74

0.10

525

79

0.11

460

86

0.12

TAP 2 (COOL/HP)

†

1235

260

0.35

1200

272

0.36

1165

284

0.38

1135

295

0.40

1100

305

0.41

TAP 3 (COOL/HP)

N/A

N/A

N/A

N/A

N/A

N/A

1250

330

0.44

1215

342

0.46

1180

354

0.47

5 kW

TAP 4 (AUX HEAT)*

1240

232

0.31

1205

248

0.33

1170

262

0.35

N/A

N/A

N/A

N/A

N/A

N/A

TAP 5 (AUX HEAT)

N/A

N/A

N/A

N/A

N/A

N/A

1260

315

0.42

1230

328

0.44

1200

338

0.45

7 kW

TAP 4 (AUX HEAT)*

1240

232

0.31

1205

248

0.33

1170

262

0.35

N/A

N/A

N/A

N/A

N/A

N/A

TAP 5 (AUX HEAT)

N/A

N/A

N/A

N/A

N/A

N/A

1260

315

0.42

1230

328

0.44

1200

338

0.45

10 kW

TAP 4 (AUX HEAT)*

1240

232

0.31

1205

248

0.33

1170

262

0.35

N/A

N/A

N/A

N/A

N/A

N/A

TAP 5 (AUX HEAT)

N/A

N/A

N/A

N/A

N/A

N/A

1260

315

0.42

1230

328

0.44

1200

338

0.45

N/A: Do not operate unit using this blower speed at this external static pressure.

† As shipped speed for Cooling operation. Blower speed must be field adjusted to Speed Tap 3 for higher duct static applications.

* As shipped speed for Heating operation. Blower speed must be field adjusted to Speed Tap 5 for higher duct static applications.

Table 3. Blower Performance (208V or 230V)

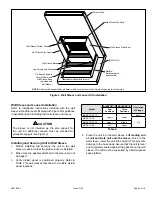

Filter

All return air must be filtered. A washable filter is furnished

with the unit, located in the return air compartment. If the

optional front return opening is used and a duct is installed,

provisions must be made to accommodate filter servicing.

If

a filter is installed at a separate central return location,

then the factory furnished filter must be removed from

the unit.

The washable filter may be replaced with a disposable

filter. Avoid filter with paper frame and media; if it gets wet,

it could collapse and block the coil, restricting airflow and

causing issues with unit operation. Table 4 lists filter sizes

that fit the unit.

When proper duct design is applied, field-provided filters

up to MERV 6 can typically be installed in the unit’s factory

filter location in lieu of a washable filter. If a higher resistance

filter is field installed in the unit, the added resistance must

be included in the external static pressure and must not

exceed 0.5 in. w.c., including ductwork.

If an installation is made in which it is more desirable to

mount the filter exterior to the unit, in the return duct work

or elsewhere, the washable filter can be used or replaced

with a disposable filter. If a disposable filter is used, in lieu

of washable filter, use the information provided in Table 5

when sizing the disposable filter.

Model Number

Filter Size

(in.)

*MHP4-12-09*

*MHP4-12-12*

18 x 20 x 1

*MHP4-12-18*

20 x 20 x 1

*MHP4-12-24*

*MHP4-12-30*

22 x 24 x 1

*MHP4-14-36*

22 x 28 x 1

Table 4. Filter Sizes