508196-01

Issue 2120

Page 11 of 18

Operation

Sequence of Operation

Upon initial “power up” to unit, there is a 3-minute time delay

to the compressor contactor (R to Y). Any 24V interrupt (R,

C) to the defrost control will initiate the 3-minute delay to

the contactor.

Cooling

When the thermostat is in the cooling mode, the O circuit

is powered which energizes the reversing valve. Upon

cooling demand, the thermostat closes circuit R to Y and

G. Closing R to Y closes the unit contactor, starting the

compressor and outdoor fan, and signaling the indoor

blower to run at cooling speed. Upon satisfying cooling

demand, the thermostat will open the above circuits and

open the main contactor, stopping the compressor and

outdoor fan. The unit is equipped with a blower OFF delay;

the blower will continue to operate for a fixed 90 seconds

after the thermostat is satisfied.

Heating

Upon heating demand, the thermostat closes circuit R to

Y, which closes the unit contactor, starting the compressor

and outdoor fan. The reversing valve is not energized in

the heating mode. The Y signal from the thermostat brings

the indoor blower on at heat pump speed. The second

stage of the thermostat closes circuit R to W, which closes

the unit sequencers, bringing the auxiliary electric heat on.

The W signal from the thermostat brings the indoor blower

on at electric heat speed. Upon satisfying heating demand,

the thermostat opens the above circuits and stops unit

operation.

The unit is equipped with a blower OFF delay; the blower

will continue to operate for a fixed 90 seconds (heat pump)

or 120 seconds (electric heat) after the thermostat is

satisfied.

NOTE:

The 7.2 and 10 kW heats strips offer a W1 and

W2 thermostat connection. Taking advantage of the two

heat strip circuits requires a 3-stage thermostat (Y for heat

pump, W1 for electric heat stage 1, and W2 for electric

heat stage 2). If a 2-stage thermostat is used, “pigtail” W1

and W2 wires together when connecting the thermostat

wires at the unit.

Defrost Cycle

If the outdoor ambient conditions are such that frost forms

on the outdoor coil, the defrost control monitors the need

for, initiates, and terminates defrost cycles as necessary to

maintain system performance.

The defrost control is time/temperature initiated and

temperature terminated with a maximum defrost time

(time-out) of 14 minutes. The time between defrost cycles

is preset at 90-minute intervals at the factory, but can be

field adjusted to 30 or 60 minutes. To field adjust time

between defrost cycles, place defrost time plug in the

proper position (see Figure 11).

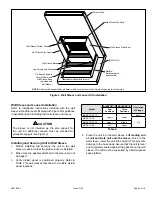

Figure 10. Defrost Control

24V TERMINAL

STRIP

CONNECTIONS

DIAGNOSTIC

LEDS

HIGH PRESSURE

SWITCH

TEST

PINS

REVERSING

VALVE

DEFROST

THERMOSTAT

LOW PRESSURE

SWITCH

SERVICE LIGHT

CONNECTIONS

FIELD SELECT

DEFROST INTERVAL

TIMING PINS

30

TEST

90

60

P1

Figure 11. Defrost Interval Timing Jumper

Defrost control will initiate a defrost cycle if the time period

has elapsed and the defrost sensor sees a temperature

below freezing. At the start of a defrost cycle, the defrost

control will energize the reversing valve solenoid, shifting

the reversing valve and de-energizing the outdoor fan.

The defrost control will also energize auxiliary heat for

increased comfort during defrost. The unit will remain in

defrost until the defrost sensor has determined that the

frost has been removed from the coil or a 14-minute time

period has elapsed.