506325-01

Issue 1734

Page 7 of 15

The location of fresh air capable models must conform to

the requirements of National Fire Protection Association

NFPA No. 54 in regards to proximity of forced air inlets

to flue gas terminals. Improper installation could result

in personal injury or death.

WARNING

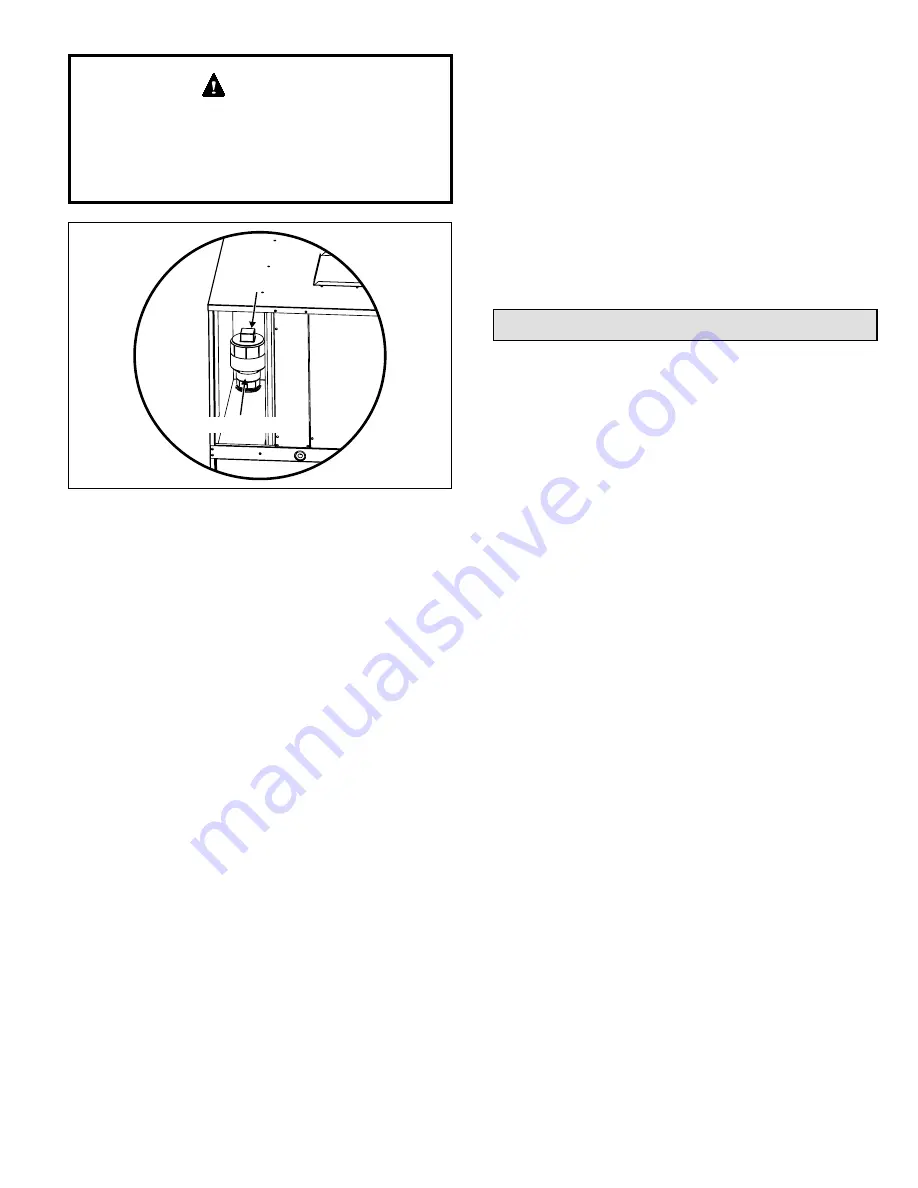

Figure 6. Fresh Air Intake Pipe and Cap

Fresh Air Intake Pipe

Threaded Cap

Thermostat

The room thermostat should be located on an inside

wall where it will not be subject to drafts, sun exposure,

or heat from electrical fixtures or appliances. Follow

manufacturer’s instructions enclosed with the thermostat

for general installation procedures. Color-coded insulated

wires (#18 AWG) should be used to connect the thermostat

to the unit.

Electrical Connections

All wiring must be done in accordance with the National

Electrical Code (NEC), ANSI/NFPA No. 70 (latest edition);

Canadian Electrical Code CSA C22.2 Part 1 (latest edition);

or local codes, where they prevail. Any alteration of internal

wiring will void certification and warranty.

Units are factory wired for a 230 volt power supply. If power

supply is 208 volts, it will be necessary to change a wire

connection on unit transformer from 240 volt terminal to

208 volt terminal as shown on the wiring diagram.

Use wiring with a temperature limitation of 75°F minimum.

Run the 208 or 230 volt, 60 hertz electric power supply

through a fused disconnect switch to the control box of the

unit and connect as shown in the wiring diagram located

on the inside of the control access panel.

The unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

or CSA C22.2 Part 1 (latest edition).

Operation

Sequence of Operation

Upon initial “power up” to unit, there is a 3-minute time delay

to the compressor contactor (R to Y). Any 24V interrupt (R,

C) to the defrost control will initiate the 3-minute delay to

the contactor.

Cooling

When the thermostat is in the cooling mode, the O circuit

is powered which energizes the reversing valve. Upon

cooling demand, the thermostat closes circuit R to Y and

G. Closing R to Y closes the unit contactor, starting the

compressor and outdoor fan. The thermostat automatically

closes R to G circuit which also brings on the indoor

blower at the same time. Upon satisfying cooling demand,

the thermostat will open the above circuits and open the

main contactor, stopping the compressor and outdoor

fan. The unit is equipped with a time delay; the blower will

continue to operate for 90 seconds which improves system

efficiency.

Heating

Upon heating demand, the thermostat closes circuit R to

Y, which closes the unit contactor, starting the compressor

and outdoor fan. The reversing valve is not energized in

the heating mode. The thermostat again automatically

brings on the indoor fan at the same time. The second

stage of the thermostat closes circuit R to W, which closes

the unit sequencers, bringing the auxiliary electric heat on.

Upon satisfying heating demand, the thermostat opens the

above circuits and stops unit operation.

NOTE:

The 7.2 and 10 kW heats strips offer a W1 and

W2 thermostat connection. Taking advantage of the two

heat strip circuits requires a 3-stage thermostat (Y for heat

pump, W1 for electric heat stage 1, and W2 for electric

heat stage 2). If a 2-stage thermostat is used, “pigtail” W1

and W2 wires together when connecting the thermostat

wires at the unit.

Power supply to the unit must be NEC Class 1 and must

comply with all applicable codes. A fused disconnect switch

should be field provided for the unit. The switch must be

separate from all other circuits. If any of the wire supplied

with the unit must be replaced, replacement wire must be

of the type shown on the wiring diagram. Electrical wiring

must be sized to minimum circuit ampacity marked on the

unit.

Use copper conductors only

. Each unit must be

wired with a separate branch circuit and be properly fused.

NOTE:

Some MHP4 models require two separate power

supply circuits. See the unit wiring diagrams and rating

plates for specifications.