506325-01

Issue 1734

Page 9 of 15

Maintenance

Disconnect all electrical power to the unit before

conducting any maintenance procedures. Failure to

disconnect the power could result in personal injury or

death.

WARNING

Periodic inspection and maintenance normally consists of

changing or cleaning filters and (under some conditions)

cleaning the coils.

Filter

Inspect the filter once a month. Replace disposable filter or

clean the washable filter as necessary (a minimum of three

times each heating or cooling season is recommended).

Do not replace washable filter with a disposable filter

unless an installation was made in which the filter was

mounted exterior to the unit.

Motors

The indoor and outdoor fan motors are permanently

lubricated and require no maintenance.

Outdoor Coil

Foreign material should not be allowed to accumulate on

the outdoor coil surface or other parts in the air circuit.

Cleaning should be as often as necessary to keep the coil

clean. To clean the coil, remove the lower access panel

and blow out debris by using compressed air or water.

Be

sure power to unit is shut off before using water to

clean the coil.

Care should be used when cleaning the coils so that

the coil fins are not damaged.

Outdoor Base Drain

Foreign material should not be allowed to clog the drain

hole. Inspect and clear drain opening prior to heating

season.

System Performance

For maximum performance of this electric cooling system,

the operating temperatures and pressures should be

checked and superheat determined at Standard ARI test

conditions of 82°F outdoor – 80°F indoor dry bulb/67°F

wet bulb. If superheat measured deviates from the values

given in Table 5, refrigerant charge should be adjusted

accordingly for maximum performance.

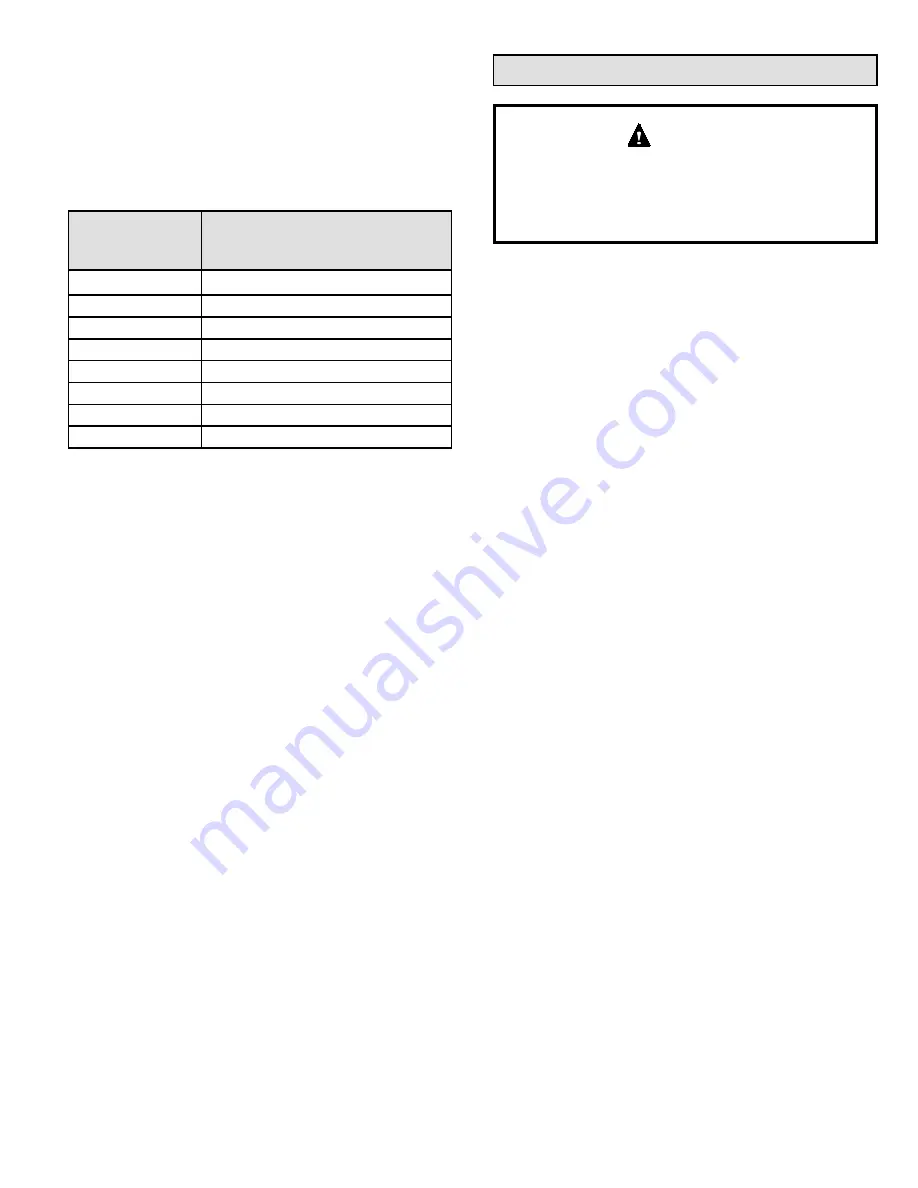

Table 5. Suction Superheat

Magic-Pak

Model

Suction Superheat @ ARI Conditions

82° OD 80° IDDB/67° IDWB

MHP4-09-12

15-18

MHP4-09-18

9-11

MHP4-09-24

17-19

MHP4-09-30

11-13

MHP4-09-36

23-25

MHP4-10-18

8-10

MHP4-10-24

16-18

MHP4-10-30

24-26