Troubleshooting

Card Warpage

During laminating, heating by the heating roller may cause warpage in cards with a low heat resistance, such as PVC ones.

If card is significantly warped

Lowering the temperature or increasing the speed helps to reduce the heat load on the card, thus causing less warpage. Alter

the temperature and speed gradually while making sure that the adhesiveness is not affected.

Settings can be changed on the status monitor of the computer that is connected to the card printer.

Laminating Condition Settings

Cautions:

If cards with low heat resistance are used, applying a large heat load at once causes the card to deform significantly, and this

may in turn cause card jam inside the laminator unit. Alter the temperature and speed gradually.

Reimbursement will not be done for poor adhesion or card warpage. For more information about the card, please consult our

authorized dealers and evaluate the settings.

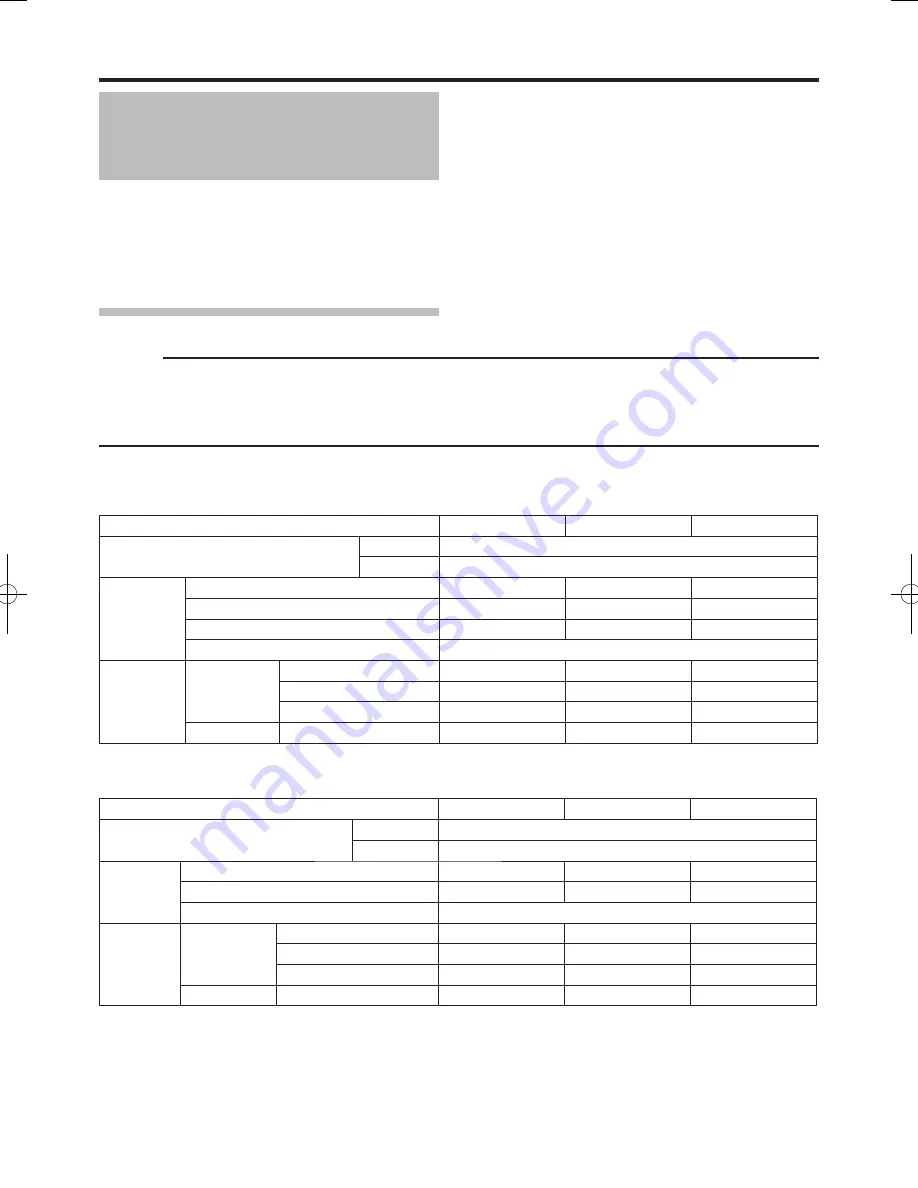

Setting example for double-sided printing and double-sided lamination

(Heat-resistant PET-G card)

Film

1mil

0.6mil

Overlay

Ambient Condition

Temperature

15 °C to 28 °C

Humidity

35 % to 60 %

Laminator

CL-600D

Temperature (Top Side)

150 °C

135 °C

120 °C

Temperature (Bottom Side)

140 °C

125 °C

110 °C

Speed

6.0 mm/s

7.0 mm/s

6.0 mm/s

Cooling Time

0 sec

Card Printer

CX-D80

Retransfer

Settings

Temperature Level

+2

+2

+2

Speed (Front)

0

0

0

Speed (Back)

+2

+2

+2

Bend Remedy

Temperature Level

Off

Off

Off

Setting example for double-sided printing and top side lamination

(Heat-resistant PET-G card)

Film

1mil

0.6mil

Overlay

Ambient Condition

Temperature

15 °C to 28 °C

Humidity

35 % to 60 %

Laminator

CL-600D

Temperature (Top Side)

170 °C

165 °C

140 °C

Speed

4.0 mm/s

5.0 mm/s

5.0 mm/s

Cooling Time

0 sec

Card Printer

CX-D80

Retransfer

Settings

Temperature Level

+2

+2

+2

Speed (Front)

0

0

0

Speed (Back)

+2

+2

+2

Bend Remedy

Temperature Level

Off

Off

Off

●

■

●

●

●

●

■

■