Installation

MKH Series Gas Griddle

L25-053 Rev. 1 (12/11)

7

1/2" BOLTS (4)

BRACKET (2)

MOUNT FLUSH

TO FRONT

(SUPPLIED)

(SUPPLIED)

NUTS & BOLTS

INCLUDED

WITH STAND

REAR

Figure 4

NOTICE

Larger models have 6 threaded receiving holes, but require only the four 1/2" bolts on each corner to

mount the griddle.

1. Remove (4) existing 1/4-20 nuts and bolts

from the rear corners of the equipment

stand.

2. Align the 2 bolt holes on the rear corners of

the stand with the 2 bolt holes on the rear

mounting brackets. Orient the brackets as

shown in Figure #4 on this page.

3. Install the provided rear mounting brackets

(2) to the rear corners by using the existing

1/4-20 hardware that were removed in step

1, tighten securely.

4. Carefully place the griddle on the

equipment stand.

5. Once the griddle is on the stand, position

the griddle on the stand so that the front

edge of the base is flush with the front of

the equipment stand. If the griddle is the

only appliance to be mounted on the stand,

then both sides of the griddle should be

flush with the sides of the equipment stand.

6. When positioned properly, the threaded

receiving holes in the griddle base should

be aligned with mating clearance holes at

the front of the equipment stand, and with

the clearance holes in the rear mounting

brackets. Install the provided 1/2" bolts and

tighten securely.

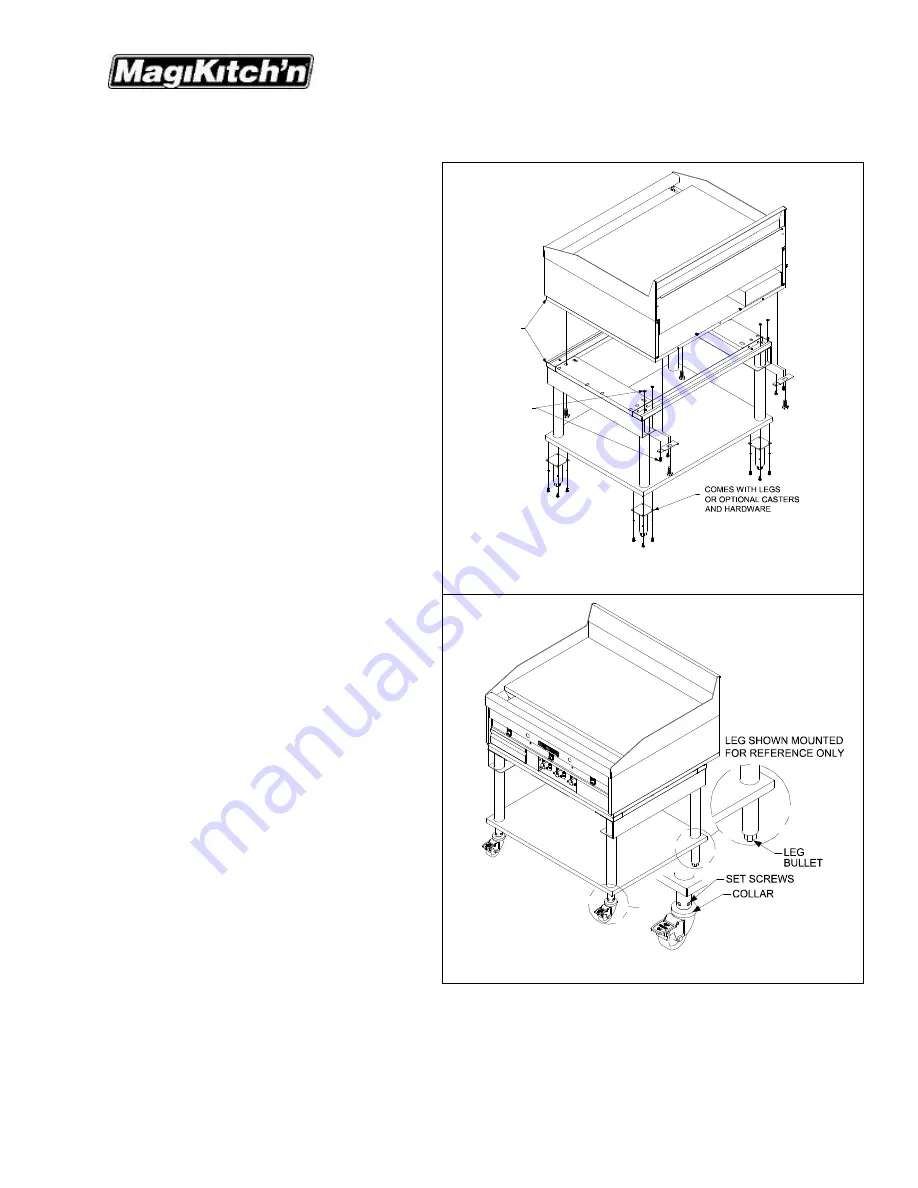

1.6.4. Leveling Instructions

NOTICE

Equipment stands are shipped from the

factory with the legs or casters set to the

minimum height adjustment. Units should be

leveled at time of installation, failure to do so

could cause the griddle to operate

improperly.

1. Identify the corner of the stand that needs to

be adjusted, remove the weight load from

the corner to be leveled.

2.

Legs-

using a wrench, or pliers turn the leg

bullet, See Figure 5, CCW to raise the

height of the equipment stand. There is ½”

to ¾” of adjustment.

Casters-

Using a Flat Head screwdriver,

loosen the set screws of the caster to be

leveled, See Figure 5.Turn the collar of the

caster CCW to raise the height of the

equipment stand. There is ¾” of adjustment.

After leveling adjustment is complete, re-tighten set screws.

3. Check the levelness of the equipment, if necessary Repeat steps 1 and 2.

NOTICE

This appliance may only be installed with casters provided by the manufacturer. When installed with

casters, a gas connection complying with ANSI Z21.69/CGA-6.16 and a quick disconnect device

complying with ANSI Z21.41/CAN 1-6.9. It must also be installed with a restraining device to guard

against putting any strain on the gas connections when the unit is moved.

Figure 5