1-800-MAGLINE (624-5463)

Page 59 www.magliner.com

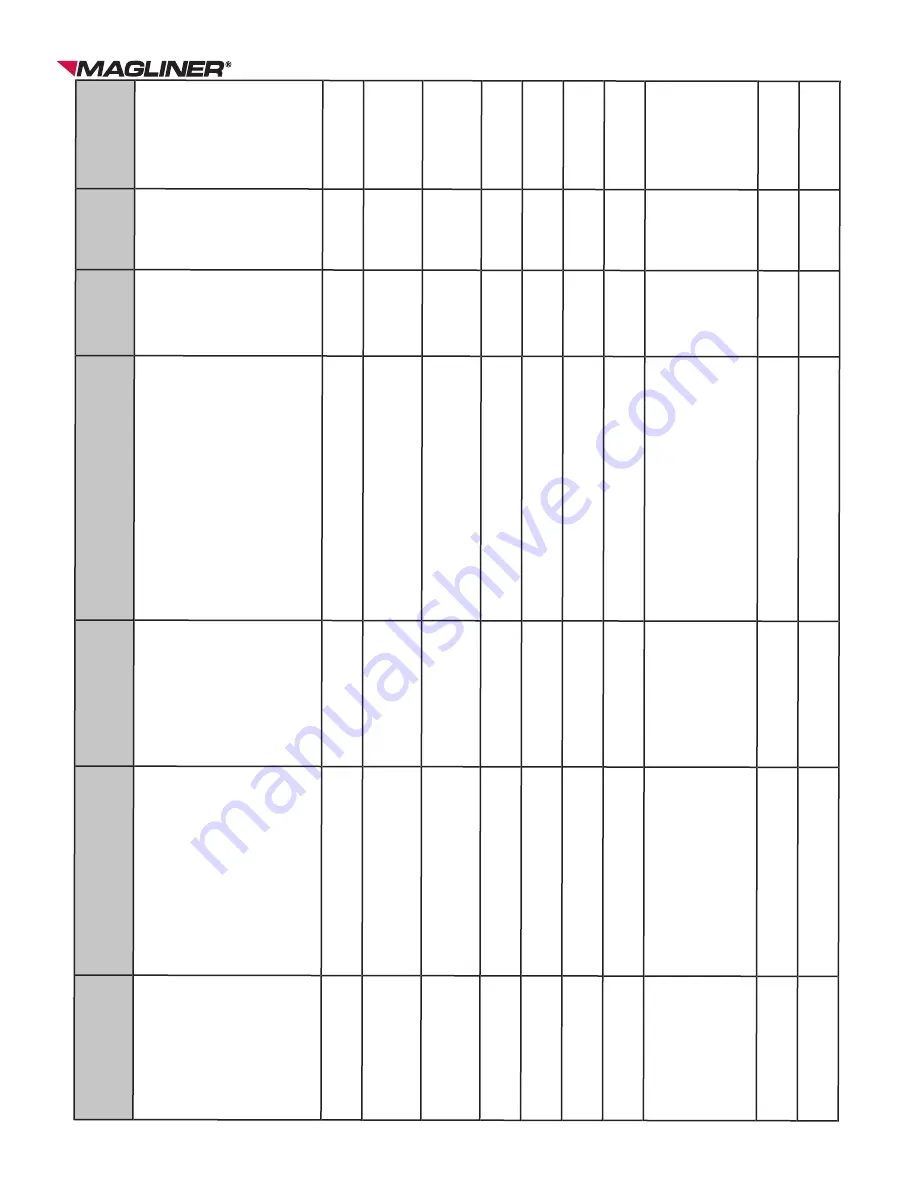

CooLift

®

Area

Description

Method of Inspection

Normal Condition

Findings

Pass or Fail

Timing

Notes

Brake System

Mounting screws tight • Master cylinder mount to handle • Master cylinder cap • Connecting block to base of enclosure • Caliper mounting

Manual inspection

•

Parts are tight to mounting surfaces

W

eekly

Brake System

Mounting screws on brake discs are tight

Visual inspection

•

Mounting screws on brake disc are not backing out

•

Brake disc is mounted tightly to the center wheel

W

eekly

Hydraulics

Cylinders not leaking (note especially front cylinder)

Visual inspection

Thin film of oil on piston rod

W

eekly

Hydraulics

Cylinder condition • No rod scoring • Return springs fully functional

Visual inspection

Cylinder rod is smooth and retracts fully into cylinder body

W

eekly

Suspension

Wheels and tires are in good condition

Visual inspection

Wheels and tires are free of damage

W

eekly

Suspension

Components are straight and undamaged • Front wheel mounting yoke • Main axle • Rear swivel caster frames

Manual inspection

•

Components are not damaged and operate freely

•

Main axle plating is not cracked or damaged

W

eekly

Operator Interface

External mounting screws are tight • Base plate mounting to frame • Enclosure mounting or base plate • Handle mounting screws • Switch mounting hardware is tight

Manual inspection

Components are tight to mounting surfaces

W

eekly

Operator Interface

•

Handle, enclosure and door are free of damage and in good condition

•

Door latches are fully functional

Visual inspection

•

Straight sections

•

Smooth curves

•

Flat surfaces

•

Minor scratches and dings are expected

W

eekly

Area

Description

Method of Inspection

Normal Condition

Findings Pass or

Fail

Timing

Notes

Operator Interface

Containment strap

Manual / V

isual

inspection

•

Belt should be free of tears and abra

sions

•

Plating on buckle should not be cracked or damaged

•

Mounting screws should be tight

•

Mounting tab should not be bent or damaged

•

Belt should retract into housing such that only the buckle protrudes

•

Housing should not be cracked or damaged

•

Strap tongue should rotate freely

W

eekly

Operator Interface

Handle grips

Visual inspection

Grips are not worn or damaged

W

eekly

Electrical

Lift system • Limit switches • Motor

Manual inspection

•

No loose components

•

Wiring harness are not damaged

•

Check connectivity

Every 2 weeks

Electrical

Propulsion system • Motor • Clutch

Manual inspection

•

No loose components

•

Wiring harness are not damaged

•

Check connectivity

Monthly

Brake System

Fluid level

Visual inspection

Fluid level up to notch in master cylinder reservoir

Monthly

Brake System

Hose without damage, abra

-

sion, wear

Visual inspection

No visible damage or wear

Monthly

Brake System

Brake discs have minimal rub and warp

Spin wheel

Wheel should continue to rotate several times before stopping

Monthly

Suspension

Wheels and casters spin freely

Manual inspection

Wheel should continue to rotate several times before stopping

Monthly

Suspension

Mounting hardware is tight • Front wheel axle/pin • Rear caster frame • Main axle mounts to frame and axle clamp • Nuts for main wheels

Manual inspection

All hardware is tight

Monthly

Hydraulics

No cracks or damage to hose or tubing

Visual inspection

No deep scratches or dents

Monthly

Hydraulics

Cylinder mount screws to frame and deck are tight

Manual inspection

Cylinder body is tight to frame; deck mounting screw is tight

Monthly