1-800-MAGLINE (624-5463)

Page 56 www.magliner.com

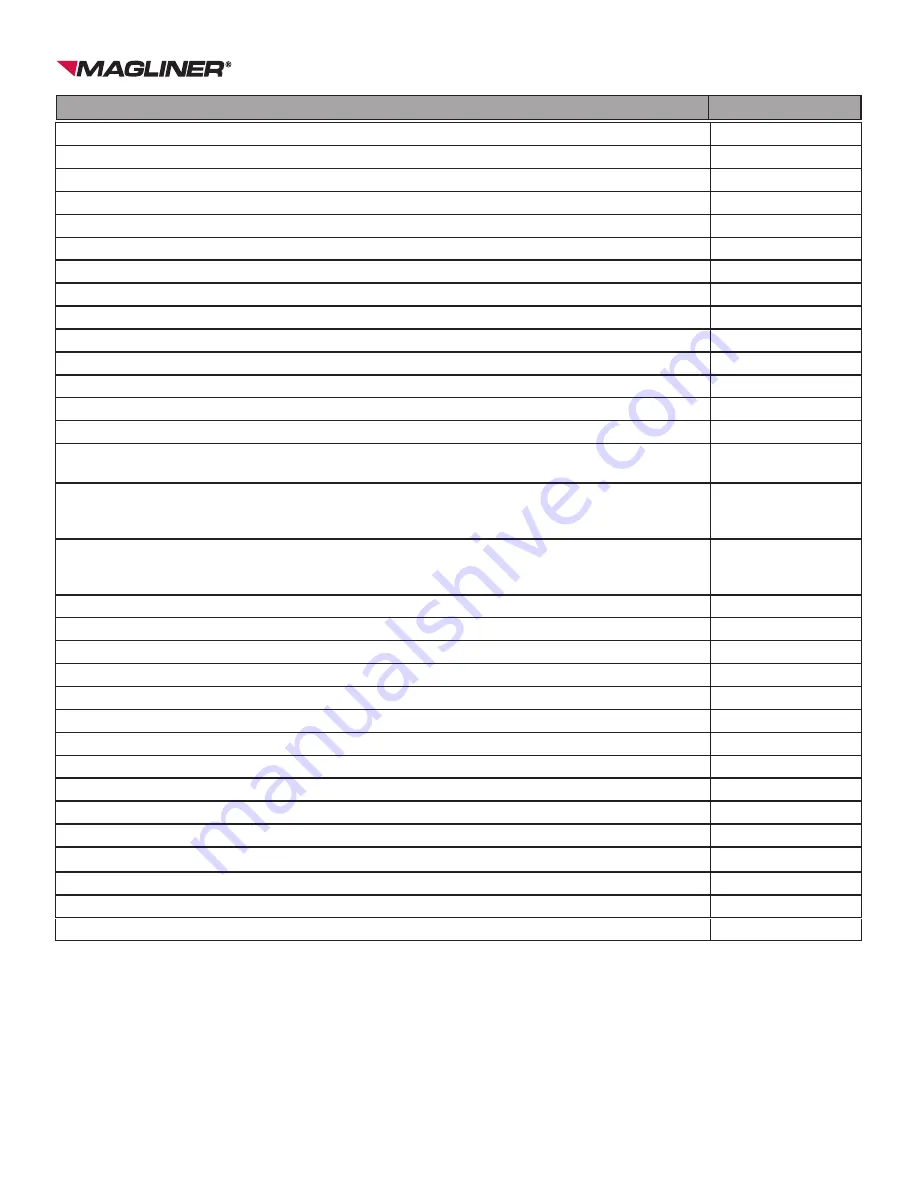

CooLift

®

Replacement Part Description

Part Number

Pan head machine screw - 1/4”-20 x 2-1/2” long

80108

Pan head machine screw - 1/4”-20 x 2-3/4” long

80111

Pan head machine screw - 1/4”-20 x 3” long

80110

Pan head machine screw - 5/16”-18 x 1-1/4” long

80313

Plug male - 115v 5-15p

61053

Pump mount plate

309062

Pump starter - 24v DC (solenoid)

63015

Round head machine screw - #10-32 UNF x 7/8” long

80122

Round head machine screw - 5/16”-18 x 1-1/2” long

80115

Saddle plate for CTA43 and CTA48

309341

Saddle plate for CTA53

309151

Spacer - 3/4” square foam, self adhesive backing

309217

Steel end cap for vertical loop handle

309049

Straight cotter pin

81142

Switch plate full assembly (includes switch plate with all wiring harnesses installed)

- use only

for CooLift units with serial numbers 3999 and lower and does not have a battery meter

309181

Switch plate service kit (includes switch plate with only charge port harness installed)

- use

only for CooLift units with serial numbers 3999 and lower and does not have a battery

meter

309181S

Switch plate full assembly for units with battery meter (includes switch plate with all wiring har-

nesses installed)

- use only for CooLift units with serial numbers 4000 and higher or if

your CooLift has a battery meter

309357

Swivel caster 6” x 2” gray thermoplastic rubber flat tread

130066

Vertical handle mount assembly

309087P

Vertical loop handle - LH

309039

Vertical loop handle - RH

309053

Washer for #6 screw - neoprene bonded

80730

Washer for CooLift wheel

80718

Wiring harness for battery box connector plug

62025

Wiring harness for battery charge meter

62032

Wiring harness for battery interconnect

62024

Wiring harness to connect battery box to on/off toggle switch

62023

Wiring harness to connect cabinet charge port to on/off toggle switch

62030

Wiring harness to connect circuit breaker to on/off toggle switch

62020

Wiring harness to connect circuit breaker to pump

62022

Wiring harness to connect pump to on/off toggle switch

62021

Yoke brush

309259